Universal Industrial Bucket Elevator

Saturday November-01 2025 17:57:54

The Universal Industrial Bucket Elevator is a device that uses buckets fixed to chains or belts to dig, lift, and unload industrial bulk materials. It can vertically lift powders, granules, small lumps, and other bulk materials from the ground or lower levels to higher levels, enabling transfer between different heights or floors. Lifting heights range from 3 to 50 meters, and the lifting capacity ranges from 5 to 500 cubic meters per hour.

The Universal Industrial Bucket Elevator is available in carbon steel for lifting non-corrosive bulk materials and stainless steel for materials requiring hygiene, corrosive materials, or in humid environments. Depending on the material type, deep, shallow, and pointed buckets are available, with bucket capacities ranging from 1L to 6L. However, it cannot be used to lift viscous, easily agglomerated wet mud, paste-like materials, high-humidity, easily adhesive strong acid or alkali materials, or high-temperature liquid materials.

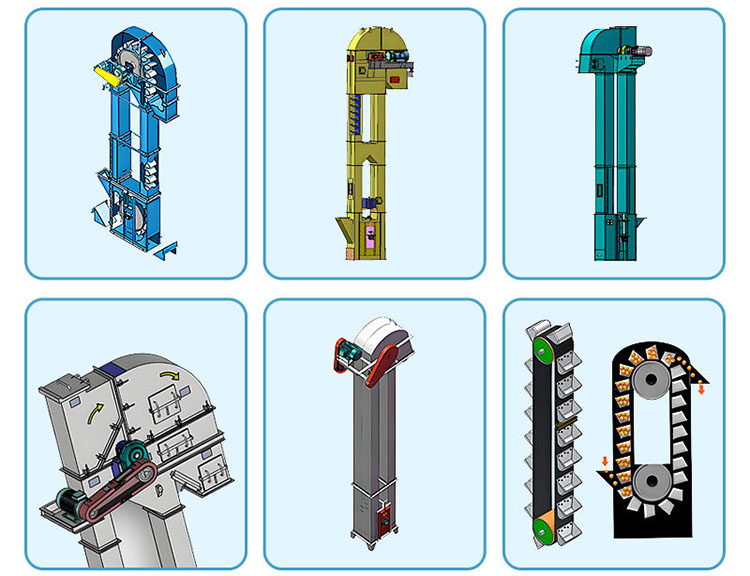

What types of Universal Industrial Bucket Elevators are available?

Universal Industrial Bucket Elevators mainly come in three types: plate chain, ring chain, and belt chain, suitable for conveying different types of materials in industry.

Plate chain Universal Industrial Bucket Elevators: These are frequently used for heavy-duty material lifting in industry because their traction components utilize high-strength, wear-resistant, and high-temperature-resistant plate chains. This structure can withstand temperatures up to 300℃, has extremely high load-bearing capacity, can withstand the impact of large materials, and has a long service life of 5-8 years. Lifting heights range from 10-50 meters, and lifting capacities range from 50-500 cubic meters per hour, meeting high-capacity lifting requirements. They can be used to lift high-density, highly abrasive materials such as ores, coke, and gravel.

Chain Type Universal Industrial Bucket Elevator: This type uses a metal ring chain as the traction device, offering excellent rigidity and toughness. It operates stably even under varying load conditions, and the chain is easy to disassemble and replace, resulting in 30% lower maintenance costs compared to plate chain types. However, the lifting height is limited to 40 meters, with a lifting capacity of 30-300 cubic meters per hour, making it suitable for medium-to-heavy-load applications. It can be used in small and medium-sized coal mines and cement plants to lift lumpy and granular materials such as raw coal, coal gangue, and cement raw materials.

Belt-type Universal Industrial Bucket Elevator: Generally uses rubber belts as the traction component. This type of belt has low operating noise, fast conveying speed, and a material damage rate of less than 1%, which can protect the integrity of fragile materials. The energy consumption is 20% lower than that of chain-type machines, but the lifting height is generally 5-30 meters; the lifting capacity is 20-100 cubic meters/hour. It is often used to lift light powdery or granular materials such as grains, flour, fertilizers, and soda ash. However, this type of belt is not suitable for materials with a temperature higher than 60℃.

What are the advantages of the Universal Industrial Bucket Elevator?

The Universal Industrial Bucket Elevator uses a vertical lifting method, saving factory space while enabling continuous material transport from low to high. It is available in both sealed and open structures. For materials containing dust, a sealed structure is suitable; for materials requiring monitoring during the lifting process, an open structure is preferable. It can handle powdery, granular, and small lump materials. Lifting heights range from 3-50 meters, and lifting capacities from 5-500 cubic meters, meeting the production capacity needs of various industries. For different types of materials, hopper size, capacity, motor configuration, and other parameters can be customized.

What is the working principle of the Universal Industrial Bucket Elevator?

When the Universal Industrial Bucket Elevator is working, material enters from the bottom through the inlet. Inside the machine, there is a ring of hoppers fixed to a belt or chain, which are circulated by a motor. When the hoppers reach the bottom inlet, they scoop up the material like ladles and then move upwards with the traction device. Once at the top, the hoppers automatically flip, throwing the material into the top outlet, which is then delivered to the desired location. The empty hoppers then rotate down the other side, returning to the bottom to scoop material again, repeating this cycle indefinitely.

Universal Industrial Bucket Elevator Parameters

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

What are the applications of the Universal Industrial Bucket Elevator?

The Universal Industrial Bucket Elevator is used in industrial applications to transport powders, granules, and small lumps of non-abrasive bulk materials. It is primarily used in the grain industry for transporting granular raw materials such as wheat, corn, and rice; in the mining industry for lifting lumpy or granular materials such as coal, ore, and slag; in the building materials industry for transferring cement, sand, gravel, and lime powder; in the chemical industry for transporting non-corrosive fertilizers and soda ash; and in the feed industry for processing feed ingredients such as soybean meal and wheat bran.

Universal Industrial Bucket Elevator Customer Cases

|

应用场景 |

提升物料 |

提升高度 |

提升量 |

|

水泥生产线 |

水泥熟料(块状) |

42.5 米 |

750 吨 / 小时 |

|

粮食仓储中心 |

小麦、玉米(颗粒) |

40 米 |

60 吨 / 小时 |

|

新能源锂电池回收 |

破碎锂电池材料(粉状) |

10 米 |

15 吨 / 小时 |

|

化肥生产车间 |

尿素颗粒(粒状) |

30 米 |

5.56 吨 / 小时 |

Universal Industrial Bucket Elevator Manufacturer

Established in 2008, DaHan Universal Industrial Bucket Elevator boasts 15 years of production and R&D experience in lifting industrial powders, granules, and lumps. Its main products include NE plate chain, TD ring chain, TH belt conveyor, and TB vertical conveyors, with a complete range of models and hourly processing capacities from 5 to 500 cubic meters. Meeting the lifting needs of everything from small workshops to large factories, the equipment is available in carbon steel and stainless steel, and in both enclosed and open structures. To meet the diverse needs of users, customized solutions are also provided, such as mobile, dust-collecting, explosion-proof, and spray-type systems.

Recommend Product

- Industrial bucket elevator

- Mining bucket elevator

- Dust-tight bucket elevator

- Heavy duty bucket elevator