Mining bucket elevator

The hopper is driven by high-strength chains or belts to lift powder, granular and other materials vertically from low to high. It is wear-resistant and resistant to high temperatures of 400°C, and is the best choice for harsh working conditions in mines.

| Conveying capacity | 5-1000m³/h |

| Lifting height | 60 meters |

| Motor power | 3-75KW |

| Hopper volume | 0.02-0.5m³ |

| Working temperature | -30℃ to + 400℃ (can be expanded under special working conditions) |

| Equipment material | Manganese steel, stainless steel 304/316L (optional) |

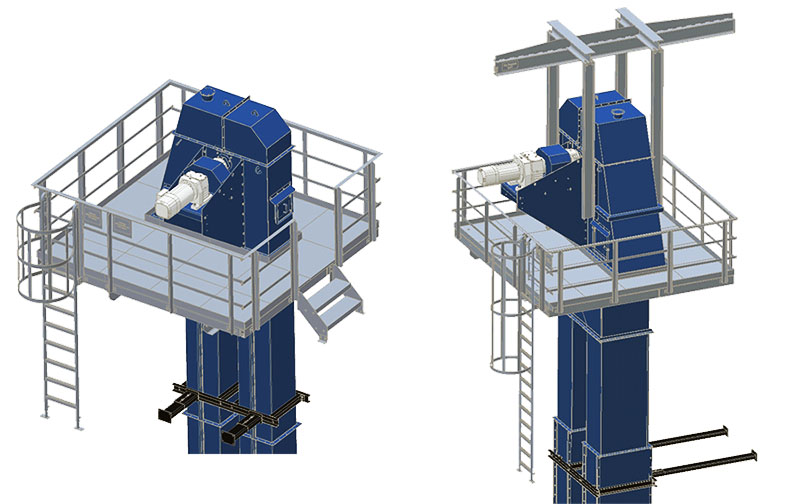

What is the mining bucket elevator?

Mining bucket elevator is an elevator used for vertical transportation of powder and granular materials such as coal, ore, cement, gypsum powder, limestone, etc. The maximum lifting height is 60 meters and the conveying capacity can reach 800 tons/hour. The bucket is made of thickened steel material (such as Q345B high-strength steel or 16Mn wear-resistant steel) to resist wear and impact, and is equipped with chain/plate chain transmission to ensure long-term stable operation.

Mining bucket elevator adopts explosion-proof motor and sealed structure, which is safe and reliable, suitable for high temperature and high dust environment. It provides different models such as TH type (ring chain type), NE type (plate chain type) and TD type (belt type) to adapt to different material characteristics and working conditions. It is widely used in coal mines, ore dressing plants, power stations, chemical plants and other fields. It is a solution for vertical transportation of mining materials!

What types of mining bucket elevators are there?

Mining bucket elevator has different traction devices and driving devices and can be divided into three types: TH chain type, NE plate chain type, and TD belt type. The appropriate model can be selected according to the characteristics of the hoisted materials and application scenarios.

TH chain bucket elevator: uses high-strength alloy steel chain, wear-resistant and tensile, suitable for large, abrasive materials (such as ore, coal gangue), lifting height ≤50 meters, conveying capacity 15-800m³/h.

NE plate chain bucket elevator: plate chain structure, stronger bearing capacity, suitable for high-temperature materials (≤250℃), such as cement clinker and metallurgical ore powder.

TD belt bucket elevator: uses high-strength rubber belt traction, bucket width 160-630mm, suitable for light powder (such as coal powder, lime powder), low noise, simple maintenance

In addition, there are TG series wire rope belt elevators for special working conditions, which are suitable for ultra-high (100 meters) grain or light material transportation.

Why choose Mining bucket elevator?

Mining bucket elevator has the advantages of high load, wear resistance, dustproof seal, low energy consumption, etc., suitable for harsh environments with high dust, high load and continuous operation.

Designed for harsh mine environment: using thickened steel plate casing and wear-resistant alloy chain/hopper, the wear resistance is improved by more than 50% compared with ordinary models, adapting to the high abrasiveness of ore, and the structural strength is increased by 30%, which can withstand the impact of large pieces of materials.

Efficient transportation: using inflow feeding + gravity unloading to avoid material return, the conveying capacity is up to 1000m³/h, which is 40% energy-saving than traditional equipment.

Sealed, wear-resistant and durable: the chain/belt is made of high-strength wear-resistant material, with a service life of more than 5 years, and the fully enclosed casing design prevents dust from spilling.

Strong adaptability: It can convey powder, granular and block materials, including highly abrasive ores and high-temperature materials (≤250℃).

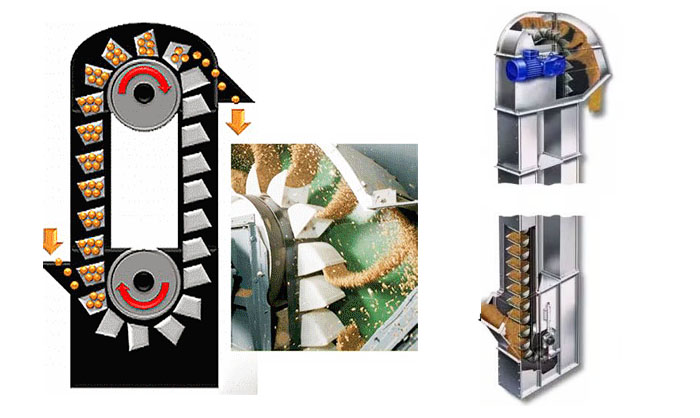

How does a mining bucket elevator work?

When a mining bucket elevator is in operation, the material is scooped up through a bucket installed at the bottom. The material can be transported in a variety of ways, such as gravity feeding or with the help of a conveyor belt. When the bucket is full, it is pulled upward by a drive mechanism. The drive mechanism can be a motor-driven pulley in a belt elevator or a sprocket in a chain elevator. As the buckets move upward along the vertical or inclined frame of the elevator, they carry the material with them. When the buckets reach the top of the elevator, they are turned over or discharged through a discharge mechanism. The material is then poured into a receiving hopper or a conveyor belt system. The empty bucket then returns to the bottom of the elevator and the process is repeated, forming a continuous material conveying cycle.

Mining bucket elevator parameters

| Model | Conveying capacity (m³/h) | Lifting height (m) | Power (kW) | Applicable materials |

| TH300 | 28-400 | 5-60 | 15-22 | Coal, ore, cement |

| NE50 | 15-300 | 10-60 | 7.5-18.5 | Mineral powder, metallurgical materials |

| NE200 | 200 | ≤60 | 22 | Highly abrasive slag, steel slag |

| TD250 | 10-150 | 5-50 | 5.5-11 | Powdered coal, lime powder |

*Note: The actual parameters need to be adjusted according to the material density (generally <1.5t/m³) and working conditions. More models can be customized.

What are the applications of Mining bucket elevator?

Mining bucket elevator is the preferred equipment for harsh working environment in mining, metallurgy, building materials and other industries. It can vertically transport fine powder to large bulk materials, such as raw coal, coal gangue, iron ore, copper ore, gold ore, cement, cement clinker, gypsum, limestone, phosphate rock, potassium salt, slag, steel slag, fertilizer, plastic particles and other materials.

Mining bucket elevator customer case

| Customer case | Application scenario | Lifting height | Lifting amount | Power/drive mode | Remarks |

| Active lime production line in Southeast Asia | Vertical transportation of limestone | 40m | 600 tons/day (multiple units) | Chain drive (TH type) | The hopper is made of wear-resistant steel and runs smoothly |

| A coal mine in Russia | Deep well ore lifting | 80m | Uncertain | Frequency conversion electric control system | Diameter 5m, the largest specification of domestic private enterprises |

| A copper and gold mine in Australia | Underground ore transportation | 60m | 1020 tons/hour | 5000kW synchronous motor (ABB drive) | Tower hoist, speed 16m/s |

| China's coking coal Zhongma Village Mine | Coal mine granular material transportation | 50m | 40 tons/hour | NE plate chain | Secondary inquiry and comparison procurement, used in coal mine scenarios |

How to choose a mining bucket elevator?

When choosing a mining bucket elevator, we need to consider the properties of the material, including the particle size, humidity, abrasiveness and temperature (≤250℃), etc., calculate the conveying capacity, and choose the appropriate model according to production needs; choose the traction method, choose the chain type for conveying large and highly abrasive materials (such as ore), and choose the belt type for conveying light powder (such as coal powder); in addition, we need to consider the automation requirements. If you want to achieve unmanned operation, you can choose an intelligent control system.