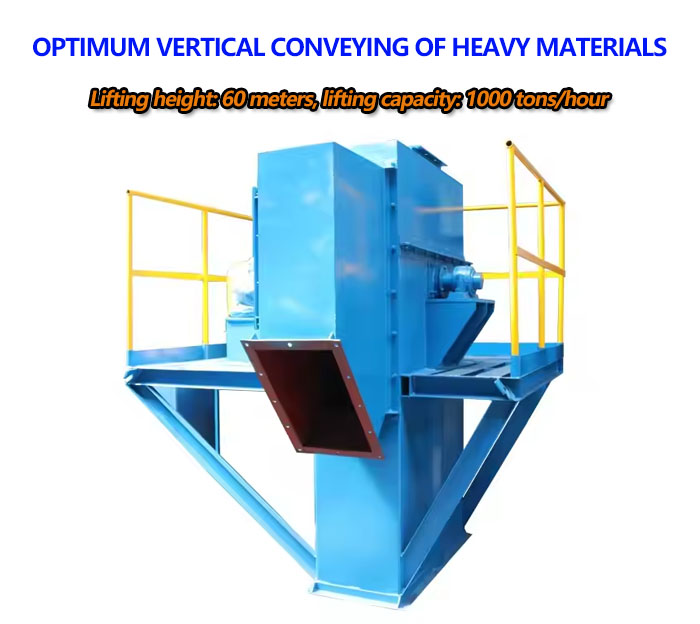

Industrial bucket elevator

Ideal for vertical conveying of heavy materials, with high load, wear resistance and intelligent control

| Conveying capacity | 5-1000m³/h (customizable) |

| Lifting height | 60 meters |

| Motor power | 3-75KW |

| Hopper volume | 0.02-0.5m³ |

| Working temperature | -30℃ to + 400℃ (can be expanded under special working conditions) |

| Equipment material | Manganese steel, stainless steel 304/316L (optional) |

What is an Industrial bucket elevator?

Industrial bucket elevator is designed for heavy industrial environment. It drives the bucket to operate through traction components (such as belts or chains) to transport powdered, granular and blocky industrial materials such as ore, chemical raw materials and coal from low position to a specified height. The lifting height can usually reach 60 meters, and the hourly conveying capacity is 5-1000 tons, depending on the model and configuration. It is suitable for working conditions with high temperature, high wear and large conveying capacity.

Compared with ordinary bucket elevators, industrial bucket elevators meet the material lifting needs under high intensity, long time and harsh working conditions. It not only "lifts" the materials, but also is a vital link in the industrial process. It bears the heavy responsibility of connecting the upstream and downstream of the production line and ensuring the continuity of production. It has higher load-bearing capacity, stronger wear resistance and more stable operating performance.

What are the types of Industrial bucket elevators?

Industrial bucket elevators can be divided into three types: chain type, plate chain type and belt type. You can choose the appropriate model according to the lifting material and application conditions.

Chain type Industrial bucket elevator (TH type): uses high-strength alloy steel round chain, suitable for large and highly abrasive materials (such as ore and coke), high temperature resistance (≤250°C), suitable for metallurgy and cement industries.

Chain type Industrial bucket elevator (NE type): uses wear-resistant steel plate chain, suitable for heavy materials (such as coal and sand and gravel), large conveying capacity, stable structure, suitable for large industrial production lines.

Belt type Industrial bucket elevator (TD type): uses steel wire core belt, suitable for powdery and small particle materials (such as cement and coal powder), stable operation, low noise, suitable for building materials and chemical industries.

What are the advantages of Industrial bucket elevator?

In addition to high load and large output to convey various industrial bulk materials, Industrial bucket elevator can work in various harsh environments, and its life span is 3-5 times longer than that of ordinary models.

High load capacity: high-strength traction chain/belt is used, and the conveying capacity can reach 1000T/h, which is far higher than ordinary elevators.

Wear-resistant design: the hopper is made of wear-resistant steel plate, and the chain/belt is specially heat-treated to extend the service life.

Anti-deviation and anti-reversal: equipped with automatic tensioning device and backstop to prevent material backflow and equipment damage.

Harsh working environment: adapt to harsh environments such as high temperature, strong abrasion, strong corrosion, and high dust to ensure stable operation of the equipment.

What is the difference between an Industrial bucket elevator and an ordinary bucket elevator?

| Comparison items | Industrial bucket elevator | Ordinary bucket elevator |

| Carrying capacity | High (up to 1000T/h) | Low (usually <50T/h) |

| Wear resistance | Using alloy steel chain and wear-resistant lining | Ordinary rubber belt or chain |

| Applicable temperature | -30°C~250°C | Usually <80°C |

| Operation stability | Anti-deviation and anti-reversal design | Basic structure |

| Application industry | Mining, metallurgy, building materials | Food, agriculture, light industry |

How does the Industrial bucket elevator work?

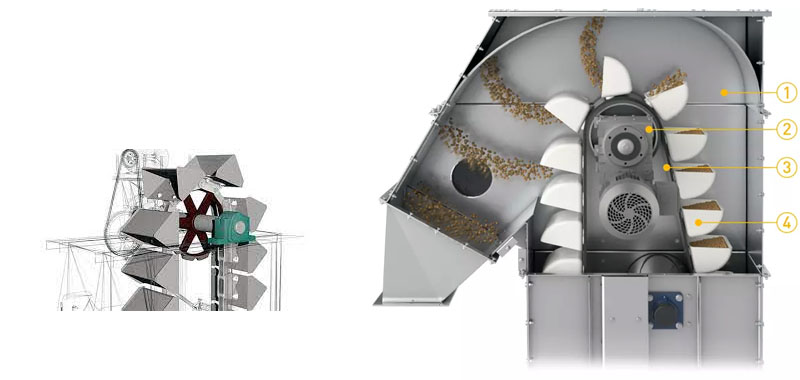

When the Industrial bucket elevator is working, the motor drives the traction member (belt or chain) through the reducer to operate, and the hopper fixed on the traction member scoops industrial materials from the feed port of the machine base; as the traction member is lifted vertically, the material rises with the hopper to the top discharge port; through the action of centrifugal force (or gravity), the material is unloaded into the designated industrial conveying pipeline or silo, forming a continuous material vertical conveying cycle. Its core technology is to optimize the hopper shape, traction speed and discharge angle according to the characteristics of industrial materials (such as particle size, density, moisture content), ensuring the transportation efficiency and stability in industrial production.

Industrial bucket elevator technical parameters

| Model | Conveying capacity (T/h) | Lifting height (m) | Power (kW) | Applicable materials |

| TH315 | 50-100 | ≤40 | 7.5-22 | Ore, coke |

| NE150 | 30-200 | ≤50 | 11-45 | Coal, sand and gravel |

| TD160 | 10-50 | ≤30 | 3-15 | Cement, coal powder |

What are the applications of Industrial bucket elevator?

Industrial bucket elevator is used to lift various powder, granular, and blocky industrial materials vertically from low to high. It is often used to lift iron ore, copper ore, coal, cement, lime, sand and gravel, fly ash from coal-fired power plants, coke, slag, metal powder, fertilizer, plastic granules, chemical raw materials and other materials

Industrial bucket elevator customer case

| Customer Cases | Application Scenario | Lifting Height | Lifting Amount | Motor Power | Equipment Model | Main Features |

| A Cement Plant in Henan | Clinker Transportation | 45m | 120t/h | 45kW | NE300 | High temperature resistant design, operating temperature ≤250℃ |

| A feed processing plant in Shandong | Corn pellet lifting | 25 meters | 50t/h | 15kW | TDTG36/28 | Food grade stainless steel, dustproof seal |

| A chemical plant in Hebei | Vertical transportation of fertilizer raw materials | 32 meters | 80t/h | 30kW | TH400 | Anti-corrosion design, acid and alkali resistant |

| A grain warehouse in a port in Guangdong | Wheat storage | 38 meters | 100t/h | 37kW | HL400 | Large-capacity hopper with explosion-proof motor |

How to select Industrial bucket elevator?

When selecting Industrial bucket elevator, it is necessary to analyze from aspects such as material properties, lifting volume, lifting height, and working environment:

Material properties: clarify the physical properties (particle size, density, moisture content, abrasiveness) and chemical properties (acidity, alkalinity, flammability) of industrial materials as the core basis for selecting traction methods and hopper materials. For example, highly abrasive ores require chain + manganese steel hoppers, and corrosive chemical raw materials require stainless steel 316L.

Working condition properties: select appropriate machine specifications based on the conveying volume requirements, lifting height, installation space, and working environment (temperature, humidity, and dust concentration) of the industrial production line. For example, open-pit mines require equipment with an IP65 protection level, and high-temperature smelting workshops require the installation of a thermal insulation layer.