Heavy duty bucket elevator

It is used for vertical conveying of large, highly abrasive materials.

| Conveying capacity | 5-1000 tons/h |

| Lifting height | 110 meters |

| Motor power | 3-1400KW |

| Temperature | ≤900℃ |

| Materials | Slag, coal, ore, chemical raw materials, flammable and explosive materials, clinker, slag |

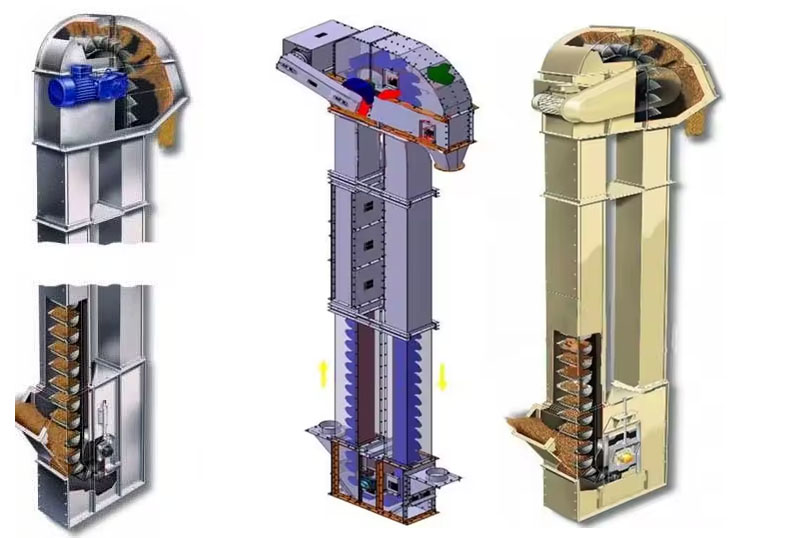

What is a Heavy duty bucket elevator?

Heavy duty bucket elevator is a bucket elevator for lifting large-capacity, high-density or abrasive powder, granules, block bulk materials (such as limestone, cement clinker, ore, etc.). It realizes the closed transportation of materials from low to high positions through the continuous circulation movement of the bucket fixed on the chain or belt, solving the problems of dust pollution and space occupation. Its maximum lifting height is 60 meters (higher can be customized). For example, the NE series has a conveying capacity of about 72-94m³/h at a height of 50 meters; the conveying capacity is as high as 800m³/h (such as NE800), and some models have a maximum capacity of 880 tons/hour.

Heavy duty bucket elevator hoppers include Q type (shallow hopper), H type (arc bottom hopper), ZD type (medium deep hopper) and SD type (deep hopper). The materials include carbon steel, alloy steel and stainless steel (304/316L) for selection.

What types of heavy duty bucket elevators are there?

Heavy duty bucket elevator can be divided into NE series plate chain bucket elevator (NE15-NE800, conveying capacity 15-800m³/h), TH/HL series chain bucket elevator (suitable for medium and low load conveying) and D-type deep bucket elevator (suitable for powdery and small particle materials); among them, NE series is the first choice for heavy-duty conditions, adopting double-row chain structure (NE50 and above) to ensure stable operation under high load. You can choose according to material properties and use environment.

What are the characteristics of heavy duty bucket elevator?

Heavy duty bucket elevator has super high wear resistance and large conveying capacity. It is very suitable for operation in harsh environments, high temperature resistance and low energy consumption:

Large conveying capacity: alloy steel plate chain is used, which has much better wear resistance than ordinary chains. The maximum conveying capacity reaches 800m³/h, which is more than 40% higher than ordinary models. The height of a single machine exceeds 150 meters, meeting the needs of large production lines.

Wear-resistant and durable: special steel and sealing structure are used to resist impact and wear, and can withstand high temperatures of 900℃, acid and alkali corrosion and dusty environments. It is suitable for highly abrasive materials such as ore and clinker.

Low energy consumption: inflow feeding reduces the return rate, and the energy consumption is only 70% of the chain hoist; the fully enclosed structure achieves a dust concentration of <10mg/m³, which does not pollute the environment.

What is the working principle of the heavy duty bucket elevator?

The operation of heavy duty bucket elevator is divided into three stages: feeding, lifting and unloading. The material enters the hopper from the bottom feed port. Driven by the traction component, the hopper rises vertically until the top discharges the material under gravity or centrifugal force, and the cycle continues.

Heavy duty bucket elevator parameters

| Model | Conveying capacity (m³/h) | Lifting height (m) | Applicable materials | Motor power (kW) |

| NE30 | 30-50 | ≤40 | Limestone, cement | 5.5-11 |

| NE50 | 50-100 | ≤50 | Lump coal, ore | 11-22 |

| NE150 | 150-200 | ≤60 | Gypsum, slag | 22-45 |

| NE800 | 800 | ≤80 | Large mines | 90-160 |

What are the applications of heavy duty bucket elevator?

Heavy duty bucket elevator can be used to transport large, abrasive and high temperature materials, such as cement clinker, raw material, slag, etc. in cement industry; iron ore, copper ore, coal, etc. in mining and metallurgy industry; fertilizer, soda ash, sulfur, etc. in chemical industry; and ash and slag in coal-fired power plants in power industry.

Heavy duty bucket elevator customer case

| Application scenario | Lifting height | Lifting amount | Power |

| A coal mine in a new energy plant in Europe | 40 meters | 300 tons/hour | 55 kilowatts |

| A port terminal in China (bulk grain loading and unloading) | 35 meters | 800 tons/hour | 90 kW |

| A cement plant in Southeast Asia (250℃ clinker lifting) | 30 meters | 500 tons/hour | 75 kW |

| Metal mine (ore lifting) | 50 meters | 400 tons/hour | 60 kW |