Corrosion-resistant bucket elevator

Made of stainless steel or polymer materials, anti-corrosion and anti-oxidation, suitable for harsh environments such as acid, alkali, salt spray, etc.

| Conveying capacity | 5-800m³/h |

| Lifting height | 4-60 meters |

| Motor power | 31.5-7.5KW |

| Temperature | -20℃~200℃ (special materials can withstand higher temperatures) |

| Hopper capacity | 3L/8L |

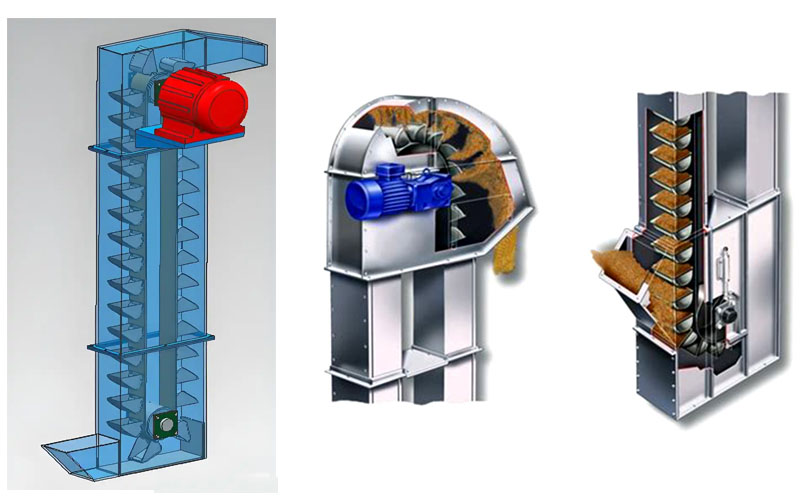

What is a corrosion-resistant bucket elevator?

The corrosion-resistant bucket elevator is specially designed for handling corrosive powder, granular and small block materials. It uses corrosion-resistant materials such as stainless steel 316L, PP plastic, PVDF coating, etc., combined with a fully sealed structure and anti-corrosion chain. It can operate stably in harsh environments such as strong acid, strong alkali, and high temperature (-30℃ to 500℃) for a long time. The equipment optimizes the hopper design (such as deep bucket, shallow bucket, arc bottom bucket) to achieve efficient lifting of powder, granular and block materials. The conveying capacity can reach 800m³/h and the lifting height can reach up to 60 meters.

Compared with traditional bucket elevators, our corrosion-resistant bucket elevator has specially strengthened the following key components:

Bucket: Made of 304/316 stainless steel or PP plastic to resist acid and alkali corrosion

Chain: Optional stainless steel chain or special coated alloy steel chain to prevent rust

Casing: Lined with polymer polyethylene material or all-stainless steel structure, double protection

Transmission parts: Specially anti-corrosion treated to adapt to high humidity environment

Why choose a corrosion-resistant bucket elevator?

The corrosion-resistant bucket elevator adopts 304/316L stainless steel or polymer polyethylene lining, which has excellent corrosion resistance and is suitable for strong acid, strong alkali, salt spray, and high humidity environments to ensure long-term stable operation and reduce the risk of downtime

Super corrosion resistance: Adopting 316L stainless steel or polymer lining, it can resist corrosive media such as H2S, Cl⁻, SO₂, and is suitable for corrosive environments.

High efficiency and energy saving: Adopting inflow feeding + induced unloading to reduce return material, improve efficiency by more than 20%, and reduce energy consumption by 15%.

Low maintenance cost: equipped with a torque protector, the bucket stops automatically to avoid equipment damage; polymer guide rails reduce wear and extend service life.

Customized solutions: support explosion-proof, airtight, automatic cleaning and other configurations to meet the needs of different industries

How does a corrosion-resistant bucket elevator work?

When the corrosion-resistant bucket elevator is working, the bucket scoops materials from the bottom, lifts them to the top through a chain/belt, and accurately delivers them through the induction discharge port.

Corrosion-resistant bucket elevator parameters

| Parameter items | TD16 | TD25 | TD30 | TD45 |

| Bucket width (mm) | 160 | 250 | 300 | 450 |

| Bucket distance (mm) | 200 | 200 | 305 | 400 |

| Dou Rong (L) | 1 | 3 | 8 | 20 |

| Conveying capacity (m³/h) | 2-5 | 4-12 | 8-25 | 15-50 |

| Chain speed (m/min) | 6-20 | 6-20 | 6-20 | 6-20 |

| Chain pitch (mm) | 100 | 100 | 152.4 | 200 |

| Lifting height (m) | 5-20 | 5-25 | 6-30 | 8-40 |

| Motor power (KW) | 1.5-4 | 2.2-5.5 | 4-7.5 | 5.5-15 |

| Applicable particle size (mm) | <20 | <30 | <40 | <50 |

| Applicable humidity (%) | ≤10 | ≤10 | ≤10 | ≤10 |

| Applicable temperature (℃) | ≤200 | ≤200 | ≤200 | ≤200 |

| Material bulk density (t/m³) | ≤2 | ≤2 | ≤2 | ≤2 |

| Chain type | Single row | Single row | Single row | Double row |

| Transmission type | Chain drive | Chain drive | Chain drive | Chain drive |

| Drive device installation | Left and right installation | Left and right installation | Left and right installation |

Where is the corrosion-resistant bucket elevator used?

Corrosion-resistant bucket elevator can be used for acidic, alkaline and high-temperature materials due to its special corrosion resistance and oxidation resistance, such as: conveying fertilizers, potash fertilizers, soda ash, dyes, plastic particles, resins, mineral powder, alumina, coke, copper chips, steelmaking dust, boiler ash, desulfurized gypsum, sludge particles, fly ash, cement, fly ash, quartz sand, kaolin, concrete additives, salt, sugar, food additives, pharmaceutical raw materials, etc. It is often used in chemical, food, pharmaceutical, environmental protection, sewage treatment, metallurgy, mining and other industries.

How to select a corrosion-resistant bucket elevator?

Determine the material characteristics (corrosiveness, particle size, humidity).

Select the material (316L is suitable for strong acid, PP is suitable for strong alkali).

Calculate the lifting capacity & height (2-800m³/h, 4-60 meters optional).

Additional functions (explosion-proof, frequency conversion, automatic cleaning).

Maintenance and after-sales service

To ensure the long-term and efficient operation of the corrosion-resistant bucket elevator, it is recommended to follow the following maintenance specifications:

Regular inspection: Check the tension of the chain/belt and the fixation of the hopper every week

Cleaning management: Remove residual materials in the equipment during shutdown to prevent corrosion accumulation

Lubrication maintenance: Lubricate the bearings, sprockets and other moving parts regularly according to the manual requirements

Anti-corrosion inspection: Check the condition of the anti-corrosion layer every month, and promptly discover and treat the damaged parts