Z type chain bucket elevator

Thursday December-18 2025 15:42:39

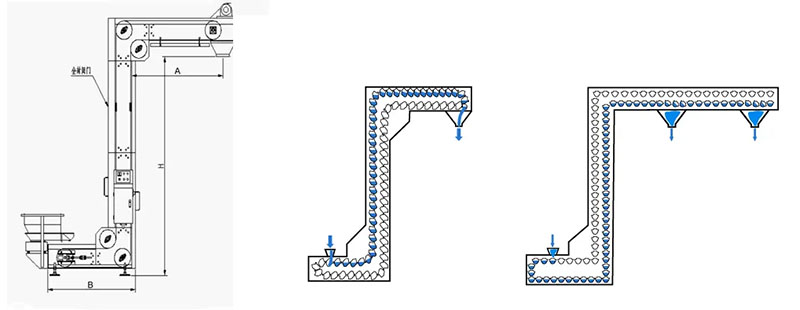

The Z type chain bucket elevator uses a combination of horizontal conveying and vertical lifting to transport materials to a designated location via a chain-driven bucket. It connects material transfer between production processes at different heights and horizontal positions. It can be used to transport free-flowing, granular, powdery, and small-lump non-sticky materials. It allows for multi-point feeding and unloading. The fully enclosed casing prevents dust leakage and material contamination. Lifting heights range from 3-30 meters, and horizontal conveying distances from 2-15 meters. The specific length can be customized by adding or removing sections of the machine body. It can meet the needs of different workshop layouts, with a conveying capacity of 5-100 m³ per hour.

Z type chain bucket elevator video

What types of Z type chain bucket elevators are there?

The type of Z type chain bucket elevator chosen depends on the properties of the materials being conveyed. For general powders and granules without special properties, carbon steel elevators are a good choice due to their wear resistance, durability, low manufacturing cost, and high cost-effectiveness. For industries with high hygiene requirements or conveying corrosive materials, stainless steel bucket elevators made of 304 or 316L stainless steel are necessary. These elevators are resistant to acids, alkalis, and high temperatures, and are easy to clean, making them ideal for environments with strict hygiene requirements, such as the food and pharmaceutical industries. For applications requiring feeding multiple silos or equipment, Z type chain bucket elevators with multi-point discharge can be selected. These elevators can be equipped with 2-7 discharge ports, allowing for simultaneous discharge or selection of a single outlet, and are commonly used for continuous feeding requirements in production lines.

What are the advantages of Z type chain bucket elevators?

The Z type chain bucket elevator features a fully enclosed casing, preventing dust leakage and environmental pollution even when conveying powdery materials. Its gentle conveying method ensures that even brittle materials will not break. Conveying length and lifting height can be customized to meet specific needs, typically ranging from 3-30 meters in lifting height and 2-15 meters in horizontal length, with a maximum conveying capacity of 100 m³ per hour. The Z-shaped design allows for flexible configuration of multiple inlets and outlets to accommodate complex factory layouts. Hopper capacity can be selected or customized based on the type of powder, granules, or lumpy materials being conveyed, with options including 1L, 1.8L, 2L, 4L, 6L, and 8L.

What is the working principle of the Z type chain bucket elevator?

When a Z type chain bucket elevator is in operation, material is fed into the inlet via a feeder or manually. The buckets, fixed to the chain, are loaded with material at the inlet. The material-filled buckets are first moved horizontally forward by the chain to a bend, then vertically lifted to a height, and finally horizontally conveyed to the outlet for unloading. Its conveying trajectory resembles a Z, a horizontal-vertical-horizontal conveying method.

Z type chain bucket elevator parameters

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

What are the applications of a Z type chain bucket elevator?

The Z type chain bucket elevator uses a combination of horizontal and vertical conveying to transport powdered, granular, and lumpy materials from a low position to a high position. It can be used in industries such as grain processing, chemicals, building materials, metallurgy, and light industry to transport materials such as grains, feed, plastic granules, fertilizers, soybeans, cement, sand, gravel, ore crushing, and biscuit blanks. It is suitable for materials with low viscosity, good flowability, and no strong corrosiveness or excessively high temperatures. The chain bucket elevator can be connected to vibrating screens, crushers, quantitative feeders, packaging machines, silos, mixers, and other equipment to form a complete material handling production line. It is suitable for practical scenarios such as feed mill pellet transfer, fertilizer plant finished product conveying, and mine coal powder hoisting, improving material transfer efficiency.

What customization options are available for the Z type chain bucket elevator?

Z type chain bucket elevators offer comprehensive customization services based on material properties, conveying capacity, and on-site operating conditions. These include adjustments to lifting height, conveying capacity, and inlet/outlet location and size to adapt to different plant layouts and process integrations. For material characteristics, bucket material, shape, and capacity can be customized for handling high-temperature, corrosive, or fragile materials. Materials include carbon steel, stainless steel, and wear-resistant steel, with bucket capacities ranging from 1L to 8L. Drive units can be matched with different power and reducer models. Accessories such as observation windows, maintenance doors, explosion-proof features, sealing, or dust collection can be added to the machine body. Furthermore, the overall material, color, and special processing requirements, such as food-grade polishing and anti-corrosion coatings, can also be customized. In addition to the Z-type, C-type, E-type, F-type, and T-type bucket elevators are also available.

Z type chain bucket elevator manufacturer

DaHan Z type chain bucket elevator manufacturer provides Z type chain bucket elevators, multi-point unloading Z type chain bucket elevators, mobile Z type chain bucket elevators, and other lifting equipment. Materials include carbon steel and stainless steel. Buckets include deep, shallow, and pointed buckets, with capacities ranging from 1L to 8L. Lifting heights can reach 30 meters, and conveying capacities range from 5-100 m³/h. A full range of models and specifications are available. Factory direct sales, prices between $450 and $7500 USD. Customization is also available based on material, lifting height, lifting capacity, and site conditions. Free drawings are provided.

Recommend Product

- Stainless Steel Bucket Elevator

- Z Type Bucket Conveyor

- Chain Bucket Elevator

- TH Chain Bucket Elevator

- Heavy duty bucket elevator