Z type Quartz Sand Bucket Elevator

Thursday October-23 2025 15:20:10

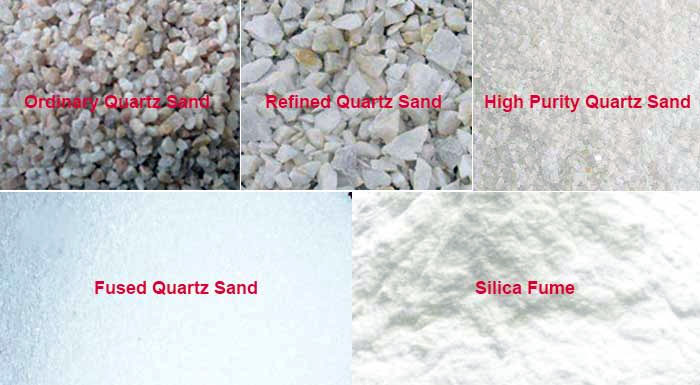

Quartz sand, as a key raw material in many industries such as glass, ceramics, casting, and water treatment, has a direct impact on production efficiency and product quality through efficient and low-loss transportation. However, traditional transportation methods often face challenges such as high material breakage rate, severe dust, and high maintenance costs. Now, we bring you a solution for efficient quartz sand transportation - Z type Quartz Sand Bucket Elevator, which is specially designed to solve the problem of conveying fine, fragile, and dusty quartz sand materials!

Z type Quartz Sand Bucket Elevator is a vertical conveying equipment designed for high hardness and high abrasive materials such as quartz sand. It combines the horizontal-vertical-horizontal Z-type path to achieve efficient and low-loss continuous conveying. Its core components are alloy steel chains, stainless steel hoppers and airtight chassis, which can cope with the harsh working conditions of quartz sand with Mohs hardness level 7. The equipment supports single-point or multi-point feeding and unloading.

Why choose Z type Bucket Elevator to transport Quartz Sand?

Low crushing rate: Inflow feeding + low-speed unloading, reduce the breakage of quartz sand particles, and ensure that the quartz sand particles are intact.

High efficiency: Quartz sand can be lifted vertically to a height of 30 meters, and the lifting capacity can reach 50 tons/hour.

Strong sealing: Fully enclosed structure to prevent quartz sand dust from leaking out, in line with environmental protection requirements.

High space utilization: Z-type structure can be transported horizontally-vertically-horizontally, adapting to narrow plant layout.

The difference between Z type Bucket Elevator and traditional elevator in transporting Quartz Sand:

| Comparison items | Z-type quartz sand bucket elevator | Traditional bucket elevator |

| Conveying path | Horizontal-vertical-horizontal (Z-type) | Vertical conveying only |

| Sealing | Fully enclosed, no dust leakage | Easy to generate dust |

| Crushing rate | <1% | 3%-5% |

| Applicable scenarios | Narrow space, multiple feeding points | Vertical lifting only |

How does the Z type Quartz Sand Bucket Elevator work?

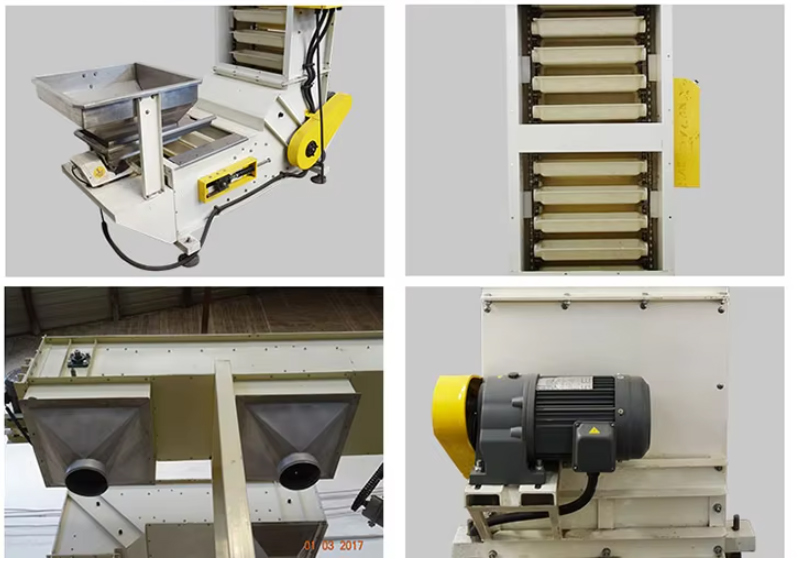

Z type bucket elevator usually uses an electric motor as the power source, and drives the transmission chain or belt through a reducer. Buckets are fixed at equal intervals on the chain or belt, and these buckets are arranged in a Z shape. When the chain or belt moves, the bucket moves with it, lifting the material from the bottom to the top. When the bucket reaches the upper discharge port, the material is automatically discharged due to gravity, and the empty bucket returns to the bottom along the chain on the other side.

Z type Quartz Sand Bucket Elevator Parameters

| Model | Conveying capacity (t/h) | Lifting height (m) | Motor power (kW) | Applicable quartz sand particle size |

| ZX-160 | 2-5 | ≤15 | 0.75-2.2 | 0.1-5mm |

| ZX-330 | 5-10 | ≤20 | 3-5.5 | 0.1-10mm |

| ZX-500 | 10-20 | ≤30 | 5.5-7.5 | 0.1-20mm |

What are the structures of Z type Quartz Sand Bucket Elevator?

Z-type bucket elevator is mainly composed of bucket, chain, traction parts, drive device and tensioning device. The bucket is made of wear-resistant and corrosion-resistant materials and can withstand high-intensity material friction and impact. It has a simple structure and stable operation, which is suitable for the transportation needs of various materials.

What are the applications of Z type Quartz Sand Bucket Elevator?

Z-type quartz sand bucket elevator is widely used in the transportation of fine, fragile, dusty or hygienic materials such as quartz sand. It can be used in the glass manufacturing industry (conveyance of quartz sand raw materials to the furnace), the chemical industry (enclosed transportation of silicon micropowder and high-purity quartz sand), the building materials industry (quartz sand is used in artificial stone and ceramic production), the photovoltaic industry (dust-free transportation of solar silicon wafer raw materials), the foundry industry (conveyance of quartz sand to sand mixers, supporting high-precision batching), etc. In addition to quartz sand, it can also transport cement, lime, slag, construction sand, fertilizer, ore and other materials.

Z type Quartz Sand Bucket Elevator Customer Case

| Application scenario | Lift height | Lifting capacity | Quartz sand particle size | Features |

| A large glass manufacturing company needs to transport quartz sand raw materials from the ground storage bin to the furnace feeding port, requiring low crushing rate + dust-free transportation. | 10 meters | 8 tons/hour | 0.2-3mm | The crushing rate is <1%, which is much lower than the 5% of the traditional elevator. The fully enclosed structure prevents dust from spilling out. It has passed the environmental protection test and saved 30% of the factory space (Z-type structure is suitable for narrow layout) |

| A photovoltaic silicon wafer company needs to transport high-purity quartz sand (SiO₂≥99.9%) from the clean workshop on the first floor to the drying line on the second floor, requiring zero pollution + anti-static. | 6 meters | 5 tons/hour | 80-120 mesh high purity sand | Completely eliminate metal pollution, meet semiconductor-level clean standards, electrostatic control effectively prevents quartz sand from adsorbing and agglomerating, modular hoppers are easy to disassemble and clean quickly |

| An artificial stone factory needs to mix quartz sand of different particle sizes (with resin in proportion, requiring multi-point precise feeding + anti-blocking material. | 15 meters (including 2 horizontal turning points) | 12 tons/hour | 0.1-5mm | Synchronous and precise feeding of 3 mixing tanks (error <2%), wear-resistant ceramic lining extends the life of the equipment by 3 times, and solves the problem of wet sand adhesion through vibration anti-blocking system |

How to choose Z type Quartz Sand Bucket Elevator?

When choosing a Z-type quartz sand bucket elevator, you need to consider:

Quartz sand characteristics: particle size (0.5-32mm, choose a standard hopper; 32mm and above, a customized reinforced hopper is required), humidity (waterproof and sealed type is required for moisture content >8%), and abrasiveness.

Conveying volume requirements: Choose a suitable model according to production capacity, such as: 80m³/h, choose ZT-20L.

Environment and plant space: The Z-type structure is suitable for confined spaces, and explosion-proof motors + anti-static coatings are required in explosion-proof areas.

Z type Quartz Sand Bucket Elevator is an ideal choice for quartz sand transportation due to its wear-resistant design, sealed and dust-proof, low breakage, high space utilization and other advantages. Whether in glass manufacturing, mining or new energy fields, its performance is significantly better than traditional equipment. Contact us now to get a customized solution to improve your production efficiency.