What is the Use of Bucket Conveyor?

Friday October-31 2025 16:03:34

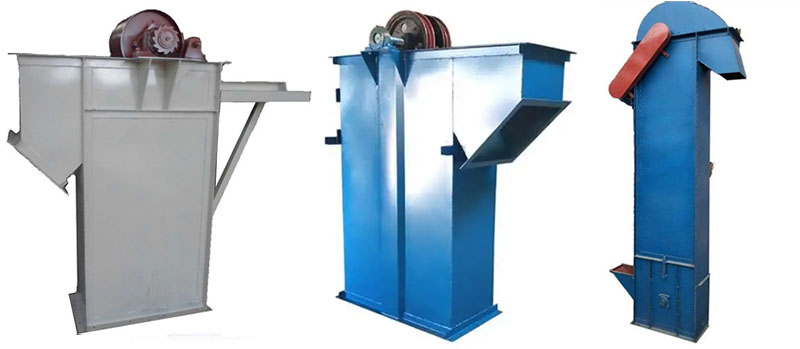

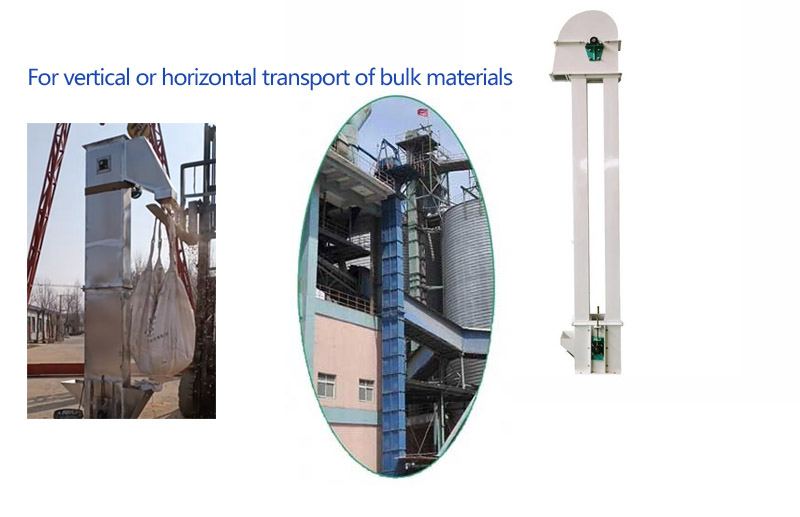

Bucket Conveyor is mainly used to vertically lift powder, granules, small blocks and other materials. It uses a hopper fixed to a traction device to lift bulk materials such as cement, grain and coal from one place to another designated height. Due to the different materials being lifted, different bucket conveyor models are selected. There are four main types including plate chain bucket conveyor, belt bucket conveyor, chain bucket conveyor and Z-type bucket conveyor.

What are the different types of bucket conveyors according to their uses?

Based on their purpose, bucket conveyors convey different materials. They can be categorized into four types: belt, plate chain, chain, and Z-type. So, what are the different materials they can convey and what are their advantages?

Belt-type bucket conveyors use a rubber belt (or steel-cored belt, heat-resistant belt) as a traction mechanism and a flow-through feed system. They are quiet, operate smoothly, and are the lowest-cost bucket conveyor. However, they are not heat-resistant (material temperatures do not exceed 120°C) and have limited load-bearing capacity. They are primarily used for low-abrasive materials such as powders (cement, gypsum powder), granular materials (grain, fertilizer), and small lumps (≤30mm, such as soybeans and coal), with lifting heights ranging from 5 to 40 meters.

Plate chain bucket conveyors use a plate chain traction mechanism. They offer high strength, high load capacity, and excellent wear and impact resistance. They are commonly used for lumpy, dense, and abrasive materials (such as cement clinker and ore). They have lifting heights of 30 to 60 meters and can transport up to 800 cubic meters. They are heat-resistant, but are heavier and more expensive.

Chain Bucket Conveyor: An economical alternative to plate chains, it uses an endless chain to pull and lift materials. It can be used for medium-abrasive materials such as powders, granules, and small pieces (e.g., cement powder and fertilizer). It can lift heights of 10-50 meters and is heat-resistant, but its operating stability and wear life are generally inferior to plate chains.

Z-type bucket conveyors: Compared to standard straight-up and straight-down bucket conveyors, this one features both horizontal and vertical zigzag conveying. Its name derives from its "Z"-like conveying path. Its lifting height ranges from 3 to 20 meters, with custom options reaching up to 30 meters. Its lifting capacity ranges from 1 to 50 cubic meters per hour. Its low-speed, stable operation and deep, leak-proof hopper reduce material collisions and compression. It's suitable for handling fragile and scratch-sensitive materials (rice, millet, and other grains, plastic pellets, and puffed foods), materials susceptible to contamination (food powders, flour, and pharmaceutical granules), and materials requiring multi-directional conveying (e.g., transporting materials from storage tanks on the first floor to mixers on the third floor within a workshop). It's commonly used in complex environments and for conveying delicate materials in industries like food, pharmaceuticals, and chemicals.

What is the Use of Bucket Conveyor?

Bucket conveyors are primarily used for vertical conveying of bulk materials. They are commonly used in industries such as grain, building materials, chemicals, and mining. They solve the challenge of vertically transferring bulk materials, efficiently conveying granular materials (such as grain and plastic pellets), powdered materials (such as cement and flour), and small lumps (such as ore and coal slag). They address the large footprint and low vertical efficiency of horizontal conveying equipment, enabling precise material delivery from low to high locations (such as silos and production line feeds). For fragile and easily contaminated sensitive materials (such as food ingredients and fine chemical granules), their shallow/curved bucket design and slow, stable operation ensure gentle conveying, preventing material breakage and quality degradation.

Bucket Conveyor Application Cases

| Application Scenario | Material Lifting | Equipment Type | Lifting Height | Lifting Capacity (m³/h) | Case Highlights |

| 600t/d Active Lime Production Line in Inner Mongolia | Limestone Granules | Chain Bucket Elevator | 35m | 180 | Suitable for high-temperature conditions, chain wear resistance and trouble-free operation |

| Large flour mill in Vietnam | Wheat | Belt bucket elevator | 8m | 120 | Sealed conveying reduces dust and prevents material damage |

| Clinker transfer line at a cement plant in China | Cement clinker (150°C) | Plate chain bucket elevator | 40m | 320 | High-temperature corrosion resistance, 60% lower failure rate |

| Potato chip packaging line at a food factory in India | Puffed potato chips | Z-type bucket elevator | 18m | 28 | Horizontal-vertical combined conveying, scrap rate <0.1% |

Bucket conveyors vary in usage scenarios and applications, requiring different equipment models and prices. Our bucket conveyors range in price from US$400 to US$7,500. You can select the appropriate model based on material properties, lifting height, and lifting capacity. We also offer customized products, such as mobile, explosion-proof, hopper-equipped, multi-point feeding/discharging, and dust collector-equipped models. We can also provide customized solutions to meet customer needs, including product customization, material customization, and scenario customization. However, the cost of a customized bucket conveyor will generally increase.