What is chain bucket elevator?

Saturday September-20 2025 14:37:10

A chain bucket elevator is a type of elevator that uses a chain to pull a hopper to vertically lift powdered, granular, or small-block materials (such as cement, pulverized coal, ore, and grain). It can vertically lift various bulk materials from the ground or a low location to another designated location, with a lifting height of up to 40 meters and a lifting capacity of 5-500 cubic meters per hour. The chain is the traction member for lifting the materials and can be selected according to the properties of the different materials being lifted. Available options include wear-resistant alloy chains (suitable for highly abrasive materials), carbon steel chains (suitable for general materials, inexpensive and durable), and stainless steel chains (suitable for corrosive materials). We can also customize these chains based on your needs.

What are the advantages of a chain bucket elevator?

The chain bucket elevator uses a chain to drive the hopper to lift materials. The chain's high structural strength makes it resistant to slipping and breaking, and it offers a strong load-bearing capacity. It is particularly suitable for lifting abrasive or high-temperature materials (≤250°C), such as ore and cement clinker. It offers high reliability and ensures continuous production. It also boasts high conveying efficiency and can stably transport large volumes, up to 500 cubic meters per hour. Its vertical or high-angle conveying method offers high space utilization, reducing floor space and making it ideal for space-constrained factories. For environments with high dust and high temperatures, such as those involving flammable and explosive materials, we also offer explosion-proof designs to prevent explosions during conveying. Furthermore, it offers low maintenance costs, with the chain and hopper being quickly accessible and replaceable, minimizing downtime and simplifying ongoing maintenance.

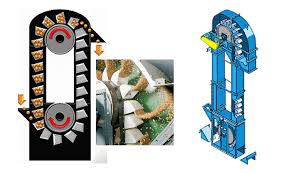

How does a chain bucket elevator work?

The chain bucket elevator uses a closed chain to pull the hopper in a circular motion, and the material enters the hopper from the bottom feed port; the chain drives the hopper to rise vertically; the material is discharged from the top by gravity or centrifugal force, and the empty hopper returns to the bottom, and the operation is cyclical.

Chain bucket elevator parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Hopper form | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Conveying volume m/h | Ordinary type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved version | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper | Hopper width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Dou Rong L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Ordinary type | 500 | 512 | 688 | ||||||||||||||

| Improved version | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter × pitch) mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Ordinary type | 9 | 7 | 7 | ||||||||||||||

| Improved version | - | 5 | 5 | |||||||||||||||

| Hopper running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Material*large piece size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

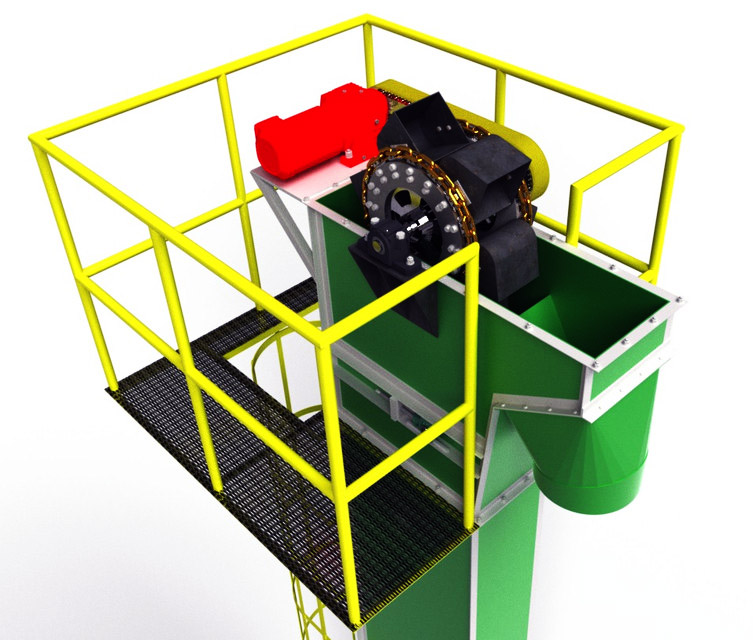

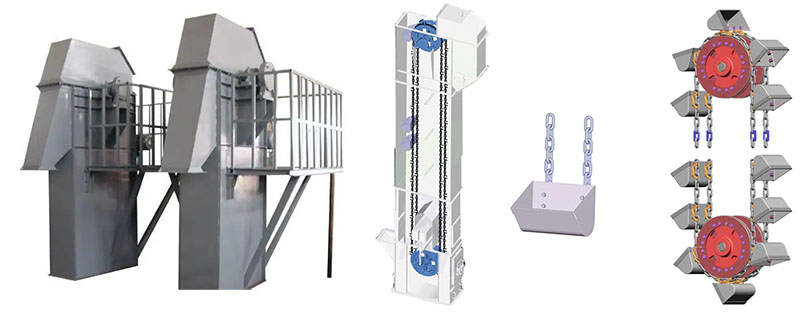

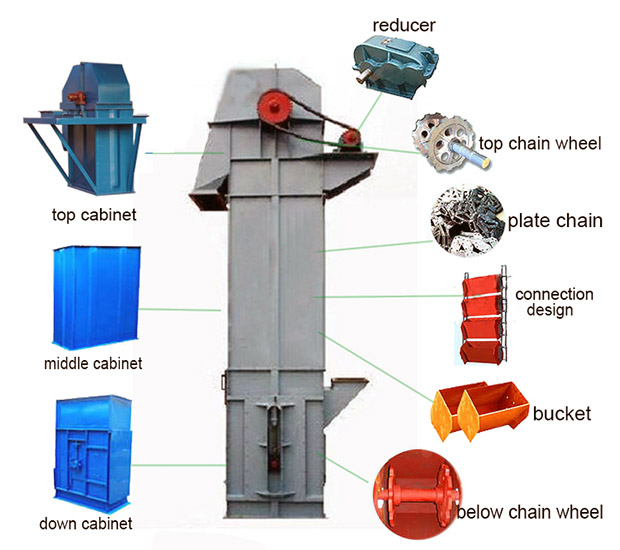

What are the structures of chain bucket elevator?

Chain bucket elevators are mainly composed of traction components (high-strength plate chain or round link chain), hoppers (S-type (powder) and D-type (granules/small pieces)), drive units (motor + reducer), housings (carbon steel or stainless steel), and tensioning devices (the tail adopts an internal and external double tensioning structure to ensure smooth chain operation).

What are the applications of chain bucket elevators?

Chain bucket elevators can vertically lift powders, granules, and bulk materials, and are commonly used in the mining, chemical, grain, and building materials industries to transport materials from one location to another. In the mining industry, they can transport bulk or granular materials such as coal and ore, connecting mining, crushing, and storage. In the chemical industry, they can safely transport corrosive or powdery materials such as fertilizers and soda ash, adapting to the closed, continuous operation requirements of chemical workshops. In the grain industry, they are commonly used to lift and transport grains such as wheat, corn, and rice, enabling efficient storage and processing in granaries and flour mills. In the building materials industry, they can transport materials such as cement, sand, gravel, and lime, connecting the raw material mixing, calcination, and finished product storage processes in building materials production. They can also be used to lift materials such as slag and waste pellets in waste treatment plants and metallurgical plants.

Chain bucket elevator customer case

| Application Scenario | Material Lifting | Lifting Amount | Lifting Height |

| A Fertilizer Plant in the United States | Granular Urea | 60 Tons/Hour | 30 Meters |

| A cement factory in Pakistan | Limestone, slag, and other raw materials | 150m²/h | 30m |

| Mining in China | Coal and ore | 1400m²/h | 30m |

| A grain processing plant in India | Wheat, corn, and other grains | 38m²/h | 20m |