What is a sugar bucket elevator?

Friday October-31 2025 16:02:35

A sugar bucket elevator is a device that vertically lifts bulk sugar using buckets on chains or belts. It can raise different types of sugar, such as powdered sugar, candy, and rock sugar, from the ground or a lower location to a designated height, with a lifting height ranging from 3 to 30 meters. It can be used in sugar factories, food processing plants, confectionery manufacturing, and beverage factories to connect different sugar processing steps such as screening, packaging, and storage, enabling the transfer of sugar between different equipment and workstations. The hourly lifting capacity is 10-50 cubic meters.

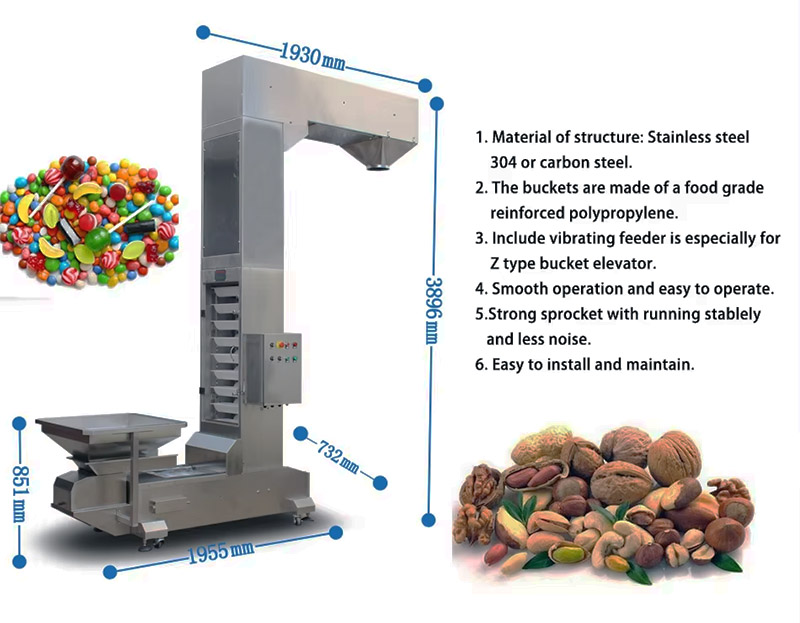

Because sugar is prone to moisture absorption, clumping, stickiness, and contamination, sugar bucket elevators are generally made of 304 or 316L stainless steel, which is corrosion-resistant, non-stick, hygienic, and rust-resistant, and also prevents cross-contamination of sugar. Regarding the buckets, shallow buckets are recommended for loose, dry sugar for faster unloading; for sugars with poor flowability, buckets with push ports can be considered to prevent clogging and reduce residue.

What types of sugar bucket elevators are available?

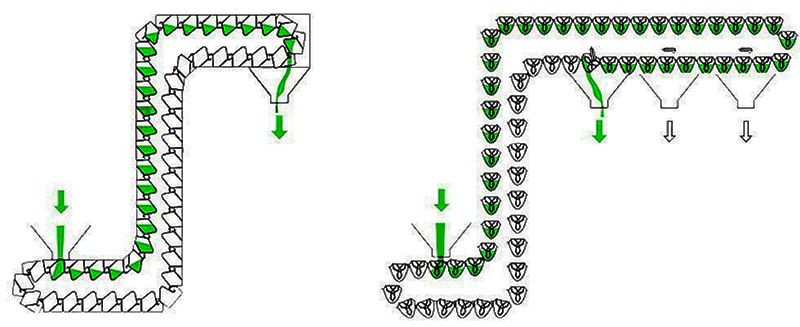

There are two main types of sugar bucket elevators available: vertical and Z-shaped. These two types differ in terms of conveying method, the shape of the sugar being conveyed, lifting height, and lifting capacity.

Vertical sugar bucket elevator: It transports sugar vertically upwards along the machine casing using buckets fixed to a belt or chain. It has a small footprint, a lifting height of 5-50 meters, and a single unit lifting capacity of 3-100 tons/hour. It can be used to transport granulated, blocky, and crystalline sugars such as granulated sugar, rock sugar, and granulated brown sugar. However, due to the large tilting angle of the buckets during vertical transport, it is not suitable for transporting easily clumped, sticky maltose, soft candy, or easily broken brittle candy.

Z-type sugar bucket elevator: It mainly uses horizontal and vertical methods to transport sugar. This method is gentler and more stable than vertical methods, with the bucket running smoothly and a low breakage rate. It is more suitable for transporting block sugars such as sugar cubes, rock sugar, and granulated sugar, as well as granulated sugars and fragile sugars. The lifting height is 3-30 meters and the lifting capacity is 5-50 tons/hour. It can achieve multi-point feeding or discharging. However, it is not suitable for transporting wet sugar with high moisture content and sugar paste materials that are easy to stick together.

What are the advantages of a sugar bucket elevator?

The advantages of a sugar bucket elevator lie in its hopper and casing, both made of 304 or 316L stainless steel, designed to meet the characteristics of sugar. The smooth surface makes it easy to clean, ensuring hygiene and preventing contamination or residue. The shallow hopper and low-speed operation allow for gentle and smooth sugar transport, preserving the integrity of the sugar granules. The transport process takes place within a fully sealed casing, preventing moisture, dust, and contamination. Furthermore, the hopper type, capacity, spacing, and height can be customized according to the sugar's properties, such as shape, particle size, and viscosity. Lifting capacities range from 3 to 100 tons per hour, meeting the needs of everything from small workshops to large sugar factories.

How Does a Sugar Bucket Elevator Work?

When the sugar bucket elevator is in operation, a hopper connected to a chain or belt scoops sugar from the bottom inlet. The full hopper is then lifted vertically upwards along the inner wall of the machine by a motor-driven traction device until it reaches the top discharge outlet. The hopper then tilts, and the sugar is automatically discharged from the outlet. The empty hopper returns to the bottom from the other end to continue operation.

Sugar Bucket Elevator Specifications

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

What are the applications of sugar bucket elevators?

Sugar bucket elevators are used in confectionery factories, sugar refining plants, and food processing plants to lift and transport sugar materials between different processing stages. They can be used throughout the entire sugar refining process in sugar factories and in the sugar ingredient preparation stage in food factories, lifting sugar materials in various forms. They can handle everything from initial processing of sugar materials after sugarcane/beet sugar refining, to refined sugar storage and transfer, and finally to loading sugar materials into pastry, beverage, and confectionery production. They can lift granulated white sugar, powdered sugar, block-shaped polycrystalline sugar, coffee sugar cubes, powdered sugar, glucose, and brown sugar and black sugar with a certain moisture content, etc.

Sugar Bucket Elevator Customer Case

| Application scenarios | Raise height | Lifting capacity | Solution | Results |

| Candy Factory | 8 meters | 3 tons/hour | Installed stainless steel bucket elevator, equipped with food-grade plastic buckets; adopts a closed design to prevent sugar powder leakage, equipped with a rapid cleaning system. | Production efficiency increased by 25%, sugar powder conveying is clog-free and waste-free; fully compliant with food safety standards. |

| Sugar Making Workshop | 12 meters | 10 tons/hour | Employs a heavy-duty bucket elevator equipped with wear-resistant steel buckets; equipped with a variable frequency motor, the conveying speed can be adjusted according to production needs. | Raw sugar conveying efficiency increased by 30%, equipment operation is stable and maintenance costs are low; production in the refining workshop is smoother. |

| Chocolate Production Line | 6 meters | 5 tons/hour | Equipped with a medium-sized bucket elevator, featuring stainless steel buckets and a dustproof design; the equipment operates quietly and meets workshop environmental protection requirements. | Unobstructed sugar conveying improves mixing equipment production efficiency by 20%; the equipment is easy to clean and meets food hygiene standards. |

Sugar Bucket Elevator Manufacturer

Dahan Sugar Bucket Elevator Manufacturer is a source manufacturer of equipment for lifting sugar materials. Our products include plate chain bucket elevators, chain bucket elevators, belt bucket elevators, and Z-type bucket elevators, with a complete range of models and specifications. We offer direct sales from the factory, a one-year warranty, and prices ranging from $410 to $7900. All equipment is made of clean and hygienic stainless steel with a polished surface for easy cleaning. In addition to standard models, we can also customize equipment according to the properties of the sugar being lifted, such as powder, granules, lumps, viscous, and flowable forms, as well as lifting height and lifting capacity requirements. Examples include explosion-proof models for conveying flammable and explosive sugar powder, mobile models that are not limited by site conditions, and models with adjustable speed and frequency conversion control systems.

Recommend Product

- Sugar Bucket Elevator

- Z Type Bucket Conveyor

- Bucket Elevator for Sugar

- Stainless Steel Bucket Elevator