What is a stainless steel bucket elevator?

Wednesday October-22 2025 14:47:17

The stainless steel bucket elevator is made of 304 or 316L stainless steel. Stainless steel is corrosion-resistant and rust-proof, ensuring that materials are not contaminated during transportation. It can be used to lift powdered, granular, and small-block materials such as grain, fertilizer, feed, pharmaceutical raw materials, and chemical powders. It utilizes a hopper connected to a belt or chain to lift materials from a low location to a high location. The lifting height ranges from 4 to 50 meters, depending on the vertical distance the material needs to be lifted to the desired position in the application scenario. For example, lifting corn from the ground to a 10-meter-high granary can be customized based on site needs. The hourly lifting capacity ranges from 5 to 100 cubic meters, making it suitable for lifting materials in various production scenarios.

Stainless steel bucket elevator can transport materials from the ground or lower position to higher equipment for processing, packaging or storage. For example, it can lift grain into a silo or flour into a packaging machine. It is commonly used for lifting materials in the food, pharmaceutical, chemical, agricultural and other industries.

What types of stainless steel bucket elevators are there?

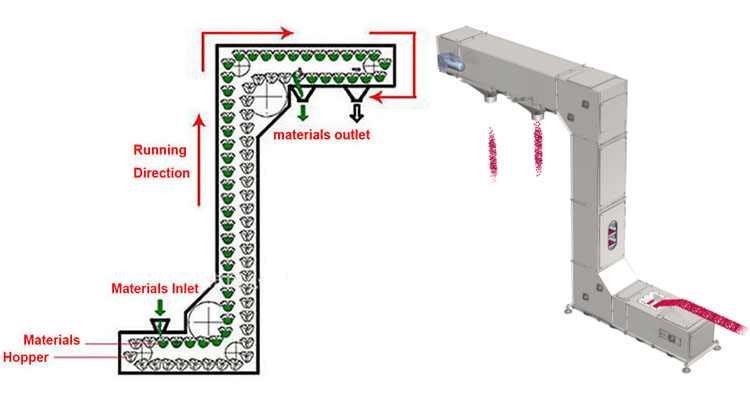

Stainless steel bucket elevators are available in two types: vertical conveying and Z-type for both horizontal and vertical lifting, depending on the material usage and lifting method.

Vertical stainless steel bucket elevators utilize vertical material lifting, occupying a small footprint. A chain/belt-driven hopper lifts materials from one location to another. They offer a high lifting capacity of up to 500 m³/hour, making them suitable for large-scale continuous conveying. They can reach lifting heights of up to 50 meters and are suitable for lifting powdery, granular, abrasive, and non-sticky materials such as fertilizer, grain, coal, sand, cement, and crushed ore.

Z-type stainless steel bucket elevator uses a combination of horizontal conveying and vertical lifting. Its conveying trajectory is Z-shaped. It adopts a gentle conveying method with a low breakage rate. It is especially suitable for conveying fragile foods such as candies and biscuits. It can realize the transfer of materials between different workstations or floors. It is often used in occasions with complex site layouts and can be fed or discharged at multiple points. Its lifting height is 3-20 meters, and its lifting capacity is lower than that of the vertical type, at 0.5-50 cubic meters/hour.

What are the advantages of a stainless steel bucket elevator?

The hopper and shell of the stainless steel bucket elevator are made entirely of 304/316L stainless steel, which is highly corrosion-resistant and rust-proof. It can operate stably in harsh working conditions such as acid, alkali, humidity, and high temperature. It can gently lift various bulk materials such as powders, granules, and blocks from low altitudes vertically to high altitudes for storage or processing through the hopper. Its surface is polished, smooth and easy to clean. It is commonly used in industries with strict hygiene requirements such as pharmaceuticals, pharmaceuticals, and chemicals. It also uses sealed conveying to prevent material contamination during transportation. The overall dimensions, hopper design, and configuration can be customized according to the different materials being conveyed. For example, bottom wheels are optional for frequent movement. When lifting flammable and explosive dust materials, an explosion-proof motor is required.

The Difference Between 304 and 316L Stainless Steel Bucket Elevators

Stainless Steel Bucket Elevators are available in two stainless steel options: 304 and 316L. 304 stainless steel is relatively inexpensive and offers excellent acid and alkali resistance, making it suitable for lifting non-corrosive materials such as grain, feed, and plastic pellets. 316L stainless steel, on the other hand, offers greater corrosion resistance and can withstand strong acids, alkalis, and high-salt environments. It can be used to lift corrosive powders in the chemical industry, high-purity materials in the pharmaceutical industry, and materials in high-salt environments like coastal areas. However, it is more expensive.

| 304 Stainless Steel | 316L Stainless Steel |

| Contains 18% chromium and 8% nickel. | Contains 16% chromium, 10% nickel, and 2% molybdenum. |

| Excellent corrosion resistance in most environments. | Superior corrosion resistance, especially in chloride-rich environments (e.g., marine or chemical industries). |

| Cost-effective and widely used in food processing, agriculture, and general industrial applications. | More expensive but ideal for highly corrosive or hygienic applications, such as pharmaceuticals or saltwater exposure. |

How does a stainless steel bucket elevator work?

When the stainless steel bucket elevator is working, the material enters the stainless steel casing from the bottom feed port. The hopper on the chain or belt scoops or receives the material into the casing. Then the motor drives the transmission mechanism, driving the hopper to rise vertically along the inner wall of the casing. After reaching the top unloading position, the hopper is turned over by centrifugal force or gravity, and the material is accurately unloaded to the top discharge port. The empty hopper returns to the bottom along the other side of the casing to scoop up the material and lift it up again.

Stainless Steel Bucket Elevator Parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m³/h | ||

What are the applications of the Stainless Steel Bucket Elevator?

Stainless steel bucket elevators are commonly used in industries with high hygiene requirements or corrosive environments, such as food, pharmaceuticals, chemicals, and feed, due to their corrosion resistance, rust resistance, and easy cleaning. They are primarily used for vertically lifting dry powdered, granular, and small-block materials. In the food industry, they are often used to lift flour, rice, candy, and grain to designated locations for processing. In the chemical and pharmaceutical industries, they are often used to lift corrosive materials such as chemical powders, acid and alkali granules, medicinal powders, traditional Chinese medicine granules, and pharmaceutical excipients. In the feed industry, they are used to lift feed pellets and grain raw materials. In the metallurgical industry, these elevators can be used to lift materials such as metal ore powders and small metal blocks, as well as hot or wet materials.

Stainless Steel Bucket Elevator Customer Case

| Application scenarios | Promote materials | Amount of improvement | Raise height | Material Selection |

| A food processing plant in China | Flour | 5 tons/hour | 10 meters | 304 stainless steel, meets food hygiene standards and withstands slight abrasion from flour and other materials |

| A chemical plant in Argentina | Hot powder | 8.5 cubic meters/hour | 18.5 meters | Customized stainless steel to handle high-temperature environments; special bucket material can withstand hot powder temperatures |

| A grain feed plant in Mongolia | Feed pellets | 10 Tons/hour | 15 meters | 304 stainless steel, meets the hygienic requirements of the feed industry and can stably convey granular materials |

| A pharmaceutical raw material production workshop in Pakistan | Pharmaceutical raw materials | 3 tons/hour | 20 meters | 316L stainless steel, with strong corrosion resistance, prevents pharmaceutical raw materials from being affected by the equipment material |

| A sugar refinery in Wyoming | Beet pulp pressing | 56 cubic meters/hour | 12 meters | 304 Stainless steel, specially designed feed port and lining to address the viscosity of beet pulp, ensuring smooth material conveying. |

Stainless Steel Bucket Elevator Manufacturer

Dahan Stainless Steel Bucket Elevator Manufacturer manufactures equipment made of 304/316L stainless steel, including the housing and hopper. Available in belt, plate chain, ring chain, mobile, and Z-type models, we offer a comprehensive range of models, with factory prices starting as low as $500 for bucket-type models. We also offer customized models and additional features based on different material properties and application scenarios, such as explosion-proof models, hopper-type models, dust removal models, and multi-point infeed or outfeed options.

Recommend Product

- Stainless Steel Bucket Elevator

- Z Type Bucket Conveyor

- Sugar Bucket Elevator

- Vertical Bucket Elevator