What is a Z Type Bucket Elevator?

Monday November-03 2025 16:23:06

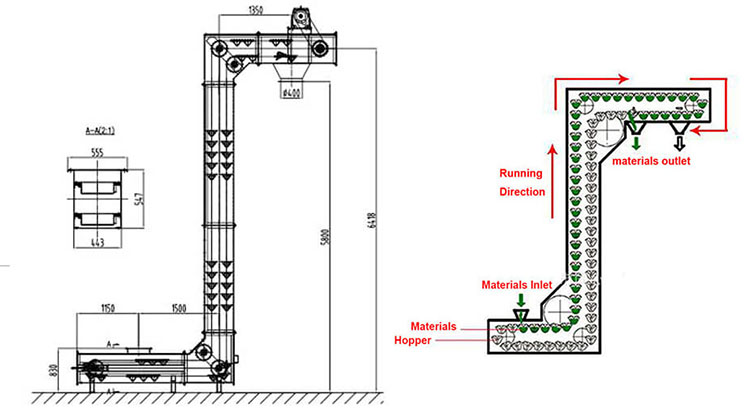

Z type bucket elevator is a type of conveyor that uses a chain to drive buckets for horizontal-vertical-horizontal combined conveying of bulk or fragile materials such as powders and granules. Its conveying trajectory resembles a Z-shape, simultaneously achieving horizontal and vertical transport, lifting bulk materials from a low position to a high position. The horizontal conveying length is 1-20m, the vertical lifting height is 2-30m, and the hourly lifting capacity is 1-100m³/h. It is available in carbon steel and stainless steel.

Z type bucket elevators can have multiple feeding and unloading points, making them suitable for complex spatial layouts or transfers between different workstations. They overcome the limitations of ordinary elevators that can only convey materials vertically. They are commonly used for conveying grains, seeds, sugar, coffee beans, and other dry products. Bucket capacities are available from 0.5-5L.

What types of Z type bucket elevators are available?

What are the advantages of a Z type bucket elevator?

A Z type bucket elevator uses a Z-shaped design, combining horizontal conveying and vertical lifting into a single conveying system, saving conveying space. It provides gentle conveying for fragile or scratch-prone materials, and the bucket speed can be adjusted as needed, reducing collision damage to granular and small block materials. The entire machine uses a sealed conveying system, effectively preventing dust leakage when conveying powdered materials. Customized products are also available based on material type, production capacity requirements, and application scenarios, including parameters such as bucket size, inlet and outlet points.

What are the applications of Z type bucket elevators?

Z type bucket elevators can be used for horizontal and vertical combined conveying to transport powders, granules, and small, fragile materials from lower to higher levels, such as wheat, corn, flour, candy granules, plastic granules, seeds, animal feed, fertilizer powder, pharmaceutical excipients, quartz sand, small cement particles, and sand. They are commonly used in food processing, grain processing, chemical, pharmaceutical, and building materials industries.

How Does a Z Type Bucket Elevator Work?

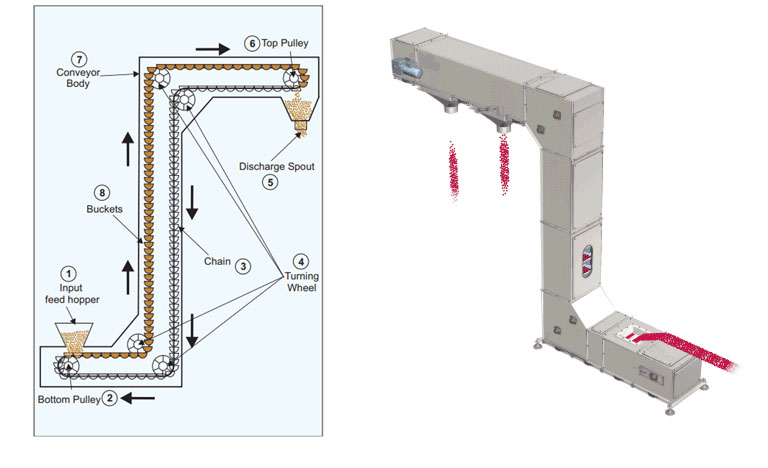

When a Z type bucket elevator is in operation, the buckets connected to the chain are loaded with material from the bottom inlet of the elevator. The material is conveyed horizontally until a bend, then the buckets are vertically lifted along the inner wall of the casing to a designated position before turning horizontal again to the outlet. The buckets then flip over to discharge the material, and the empty material returns to the bottom along the other side to continue working.

Z Type Bucket Elevator Parameter

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

What are the structural components of a Z-type bucket elevator?

The Z type bucket elevator mainly consists of an inlet, horizontal section, vertical section, outlet, hoppers, motor, gearbox, pulleys, and a sealed casing. The hoppers for loading materials are made of plastic or stainless steel and are designed as deep, shallow, or pointed hoppers according to the material characteristics to ensure efficient scooping and unloading. The drive unit, generally located at the top of the equipment, consists of a motor, reducer, and drive sprockets/rollers, providing power for the entire machine. Next is the transmission assembly, including chains or belts, which connect the hoppers and transmit power. Wear-resistant chains are suitable for heavy granular materials, while food-grade belts are used for easily contaminated materials. The casing, made of welded steel plates or stainless steel, is shaped like a "Z" to cover the conveying path, achieving a sealed dustproof design. The bottom is equipped with guide wheels and a tensioning device.

Z type bucket elevator customer case

A food processing plant in Southeast Asia needed to transport flour and sugar between different stages of production, but with limited space, they required a compact and efficient system to move materials vertically and horizontally. They chose stainless steel Z type bucket elevator, equipped with food-grade hoppers and a low-speed operating system, which reduced material damage and waste, increased production efficiency by 50%, and the stainless steel material met all food safety and hygiene standards.

Z type bucket elevator manufacturers

Depending on the type of granular, powdery, or small block materials being conveyed and the application scenario, Dahan Z type bucket elevator manufacturers offer combinations of Z, C, T, and E types. They primarily utilize belt and chain drive systems. Material options include powder-coated carbon steel for the frame and 304/316L stainless steel. Bucket materials include food-grade PP, ABS, stainless steel, and carbon steel. Lifting heights typically range from 2 to 30 meters. Furthermore, customized features can be provided for standard models that do not meet specific needs. For example, structural options include multiple feed/discharge ports and Z+C hybrid paths; control systems can include variable frequency speed control and PLC program control; explosion-proof motors can be added for flammable and explosive dust. Customized solutions can also be provided based on material characteristics such as corrosivity, humidity, conveying capacity (3-100 m³/h), and industry standards such as food-grade certification.

Recommend Product

- Z Type Bucket Conveyor

- Sugar Bucket Elevator

- Stainless Steel Bucket Elevator

- Food Grade Bucket Elevator