What is a Grain Bucket Elevator?

Friday October-17 2025 14:58:17

Grain Bucket Elevator is an elevator used for vertical transportation of granular or powdered grain and similar grain materials. It continuously scoops grain through the hopper and lifts it vertically from a low position to a specified height. It solves the problem of connecting and conveying grain between equipment at different heights, such as silos, mills, and conveyor belts, reducing labor handling costs and preventing grain from scattering, moisture, and contamination during transportation. It has a lifting height range of 3-50 meters and a lifting capacity of 5-100 cubic meters per hour. It can be used in grain processing or storage production lines.

The Grain Bucket Elevator transports bulk grains such as wheat, corn, rice, and flour vertically from the feed point to storage silos, processing units, or packaging lines. Its housing is available in affordable, durable carbon steel or acid- and alkali-resistant stainless steel. The hopper can be constructed of either polypropylene (PP) plastic (lightweight and wear-resistant, suitable for small and medium-sized grains) or steel plate (highly strong, suitable for large or hard grains). However, a Grain Bucket Elevator is not suitable for conveying sticky, wet, or highly corrosive grains, as these materials can accelerate equipment damage. If this is required, contact the manufacturer for modifications or additional features.

What types of grain bucket elevators are there?

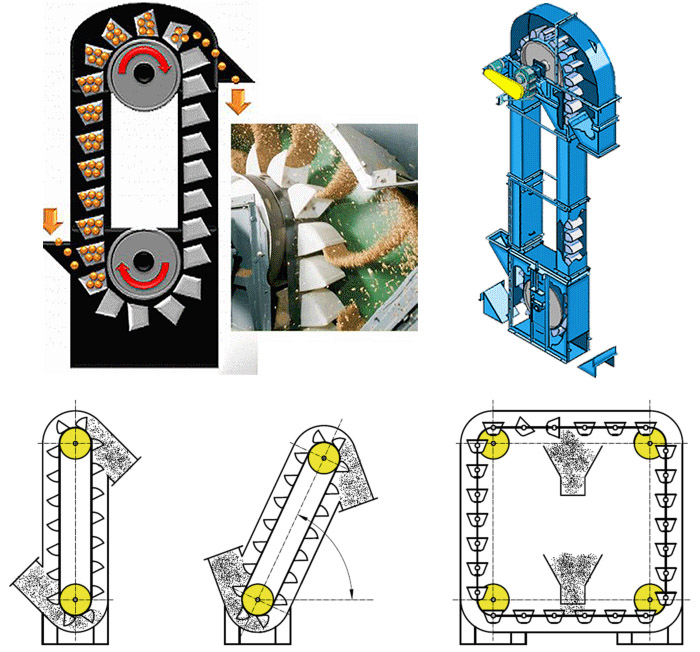

Grain bucket elevators are available in three types depending on the type of grain being hoisted: plate chain for large, highly abrasive grains; belt for small, powdered grains; and continuous for fine grains and materials with a moisture content of less than 15%. The appropriate type can be selected based on the grain's properties.

Plate chain grain bucket elevators: Utilizing high-strength alloy steel plate chains, they are highly wear-resistant and can withstand significant impact. They are commonly used for lifting granular, small-piece, and powdered grains such as corn, soybeans, wheat, sorghum, rice, and flour, as well as large, highly abrasive, hulled grains, cleaned impurities, and grain dried at temperatures ≤250°C. They can reach a lifting height of 60 meters and a lifting capacity of 15-800 m³/h. However, they are expensive and require regular maintenance.

Belt-type grain bucket elevators: Utilizing rubber belt traction, they are quiet, minimize damage to grain, and are inexpensive. They are suitable for grains with good flowability, low abrasiveness, and medium-sized pieces, such as wheat, rice, flour, bran, and rapeseed. However, their lifting height does not exceed 40 meters. They are not heat-resistant, and large grains can easily damage the belt.

Continuous Grain Bucket Elevator: This model provides continuous, uninterrupted grain conveying. Its hoppers are densely arranged, using inflow feeding and gravity discharge. It is commonly used for powdered, small-particle grains, and grains with moisture content below 15%, such as flour, cornmeal, broken rice, and feed pellets. It is particularly suitable for handling fine materials (such as rice) that must be prevented from breaking, and for high-volume, continuous operations (such as feed mills). However, the elevator is limited to a lifting height of no more than 30 meters, and grain moisture content greater than 15% can easily cause clogging.

What are the applications of the Grain Bucket Elevator?

The Grain Bucket Elevator can lift various types of grains vertically from one location to another, including powdered flour, rice flour, bean flour, and granulated wheat, rice, millet, oats, corn, soybeans, and sorghum. Grain Bucket Elevators are commonly used for grain processing and storage in flour mills, fertilizer plants, ethanol plants, malt plants, and feed processing plants.

In grain storage, the Grain Bucket Elevator can transport bulk grain from the ground to 50-meter-high silos for storage. It can also transport grain from silos to transport vehicles or subsequent processing equipment upon shipment.

In grain processing, the Grain Bucket Elevator can connect to processing equipment at different heights, such as cleaning, husking, milling, and flour milling, enabling the transfer of raw grain, semi-finished products, and finished grain.

In ports and logistics hubs, the Grain Bucket Elevator can be used in conjunction with grain unloaders to transport arriving bulk grain from cargo ships and train cars to transit warehouses or directly load onto trucks for transshipment.

What are the advantages of a grain bucket elevator?

The Grain Bucket Elevator features a vertical structure, making it ideal for space-constrained environments such as tall silos and multi-story processing halls. It lifts grain from the ground to the silo at heights ranging from 3 to 50 meters, with customizable heights available. It has a lifting capacity of up to 100 cubic meters. It is available in both open and sealed configurations. The sealed configuration prevents moisture and dust contamination during grain transport. For particularly dusty materials, we also offer a dust collection system that directs dust generated during transport to a dust collector for purification. A mobile version is available for applications requiring frequent changes in workstations. The hopper type (deep, shallow, or inclined) can be selected based on the characteristics of the material being lifted, and the adjustable hopper size and speed accommodate varying grain types and moisture levels.

How does a grain bucket elevator work?

Grain Bucket Elevator Specifications

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

What equipment can the Grain Bucket Elevator be used with?

Grain Bucket Elevator can lift grain to a designated location or silo for temporary storage, and can also be used with other equipment such as screening machines, grinding machines, and packaging machines to process grain. For example, it can lift grain from the silo to a screening machine for screening and removal of impurities, lift grain to a de-stoning machine to separate stones and mud from the raw grain, lift rice to a thresher for husking into rice, or send clean grain to a grinding machine for wheat grinding, corn flour making, and other operations; and lift finished grain to a packaging machine for packaging, etc., to meet the needs of different grain processing links.

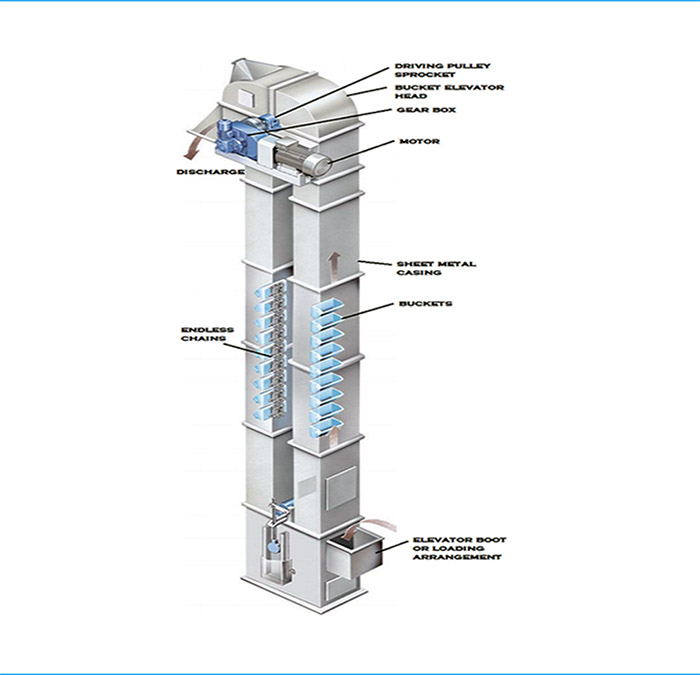

What are the structural components of a grain bucket elevator?

The main components of a grain bucket elevator are the hopper (a metal or plastic container, such as ABS, used to transport grain), the chain/belt (which drives the bucket; chains are preferred for heavy-duty applications), the drive system (which includes the motor, sprockets, and gearbox to control speed), the casing (an enclosed structure to prevent dust and spillage), and the tensioner (which adjusts the chain/belt tension for optimal operation).

Grain Bucket Elevator Customer Case

| Application Scenario | Material Lifting | Lifting Height | Lifting Capacity |

| A Large Grain Storage Base in Pakistan (Lifting Freshly Procured Grain from Transport Vehicles into Large Silos) | Raw Grains, Such as Wheat and Corn | 25 Meters | 150 Tons/Hour |

| A flour mill in China (transporting wheat to cleaning and grinding equipment, and then transporting the processed flour to the packaging workshop) | Wheat, flour | 18 meters |

80 tons/hour (wheat) 30 tons/hour (flour) |

| A grain processing company in India (lifting grains from the raw material warehouse to the processing equipment) | Small grains such as millet and sorghum | 12 meters | 25 tons/hour |

| A grain transfer station at a Vietnamese port (transferring grain from ships to the terminal storage area) | Soybeans, rice, etc. | 30 meters | 200 tons/hour |

Grain Bucket Elevator Manufacturer

Dahan Machinery is a manufacturer of Grain Bucket Elevators specializing in grain processing and bulk material conveying. With 15 years of production and R&D experience, we produce a full range of equipment models, including plate chain, ring chain, belt and Z-type. All prices are ex-factory prices, and the quality is guaranteed. We can also provide customized solutions based on the customer's lifting material properties, lifting height, lifting volume and usage scenarios to meet the needs of different grain processing scenarios.