What is Chain Type Bucket Elevator?

Tuesday October-21 2025 15:19:39

Chain Type Bucket Elevator is an elevator that realizes vertical material transportation by fixing the hopper on the chain. It can lift bulk materials such as cement, aggregate, limestone, seeds, grains, powders, granules and blocks from low places to high places. It can also lift heavy, abrasive or high-temperature materials. It is the preferred equipment for harsh industrial environments. Its lifting height is 5-60 meters and the lifting capacity is 10-500 cubic meters per hour. It is made of carbon steel or stainless steel according to the different materials to be transported. The hopper has deep and shallow options.

What types of Chain Type Bucket Elevators are there?

Chain Type Bucket Elevator has two types, depending on the material being lifted the ring chain type for small, medium and low hardness materials and the plate chain type for large, high hardness, and highly abrasive materials. Different equipment models are selected for different materials.

Ring Chain Type Bucket Elevators use a ring chain as a traction mechanism, with the hopper attached to two parallel ring chains. They can be used for materials with medium hardness and no sharp edges, such as pulverized coal, cement, grain, and fertilizer. They have a lifting capacity of 10-100 m³/h and can reach heights of up to 40 meters. They should not be used for large, abrasive materials with a particle size of ≤50 mm, as these will quickly wear out the chain.

Plate Chain Type Bucket Elevators use a plate chain as a traction mechanism, with the hopper directly connected to the plate chain. They are commonly used for conveying abrasive, bulk and powdery materials such as cement clinker, slag, ore, and crushed stone. Material temperatures can reach 300°C, and they have a high lifting capacity of 50-500 m³/h and can reach heights of up to 60 meters.

What are the advantages of a Chain Type Bucket Elevator?

The Chain Type Bucket Elevator uses a high-strength chain as a traction member, offering high tensile strength and excellent wear resistance. It can operate stably and continuously in harsh, high-load environments, handling heavy and large materials, and even high-temperature materials up to 300°C. For sites with limited space, it uses vertical conveying, occupies a small footprint, and is well-suited to various production workshops. It can also handle a maximum conveying capacity of 500 cubic meters. The entire conveying process is carried out within a sealed enclosure, eliminating dust leakage and environmental pollution. It can also be customized based on the site and material, including dimensions, hopper, speed, configuration, and additional features such as explosion-proof and mobile versions.

How does a Chain Type Bucket Elevator work?

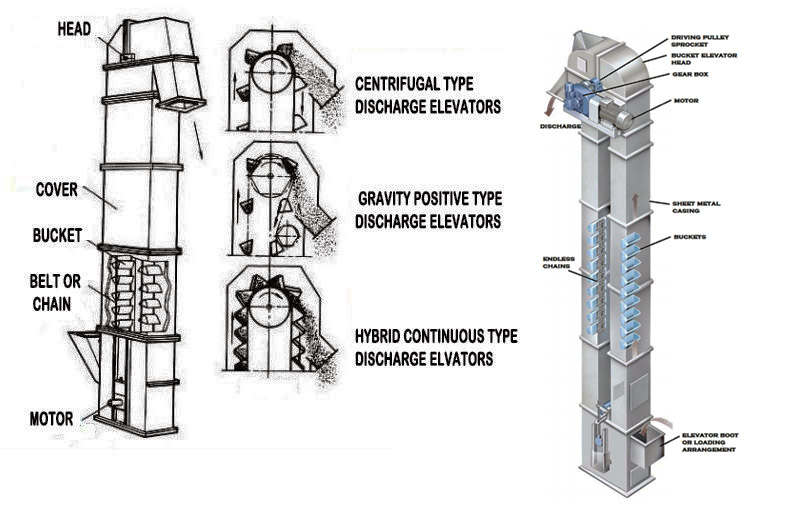

When a Chain Type Bucket Elevator is in operation, a hopper attached to a chain scoops material from the bottom feed port. The filled hopper is lifted vertically upward along the machine casing until it reaches the top. Under the influence of gravity or centrifugal force, the hopper automatically flips over and discharges material from the discharge port. The empty hopper returns to the bottom at the other end to continue the loading cycle.

Chain Type Bucket Elevator Parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Hopper form | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Conveying volume m/h | Ordinary type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved version | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper | Hopper width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Dou Rong L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Ordinary type | 500 | 512 | 688 | ||||||||||||||

| Improved version | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter × pitch) mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Ordinary type | 9 | 7 | 7 | ||||||||||||||

| Improved version | - | 5 | 5 | |||||||||||||||

| Hopper running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Material*large piece size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

What are the differences between a Chain Type Bucket Elevator and a belt bucket elevator?

While both Chain Type Bucket Elevators and belt bucket elevators are used for vertically lifting materials, they differ in their structure, principles, and the materials they are used for.

| Differences | Chain Type Bucket Elevator | Belt Bucket Elevator |

| Working Principle | A chain (link chain/plate chain) is used as the traction member, and the sprocket and chain mesh to drive the bucket to lift the material. | The belt is used as the traction mechanism, and friction between the drive roller and the belt drives the hopper to lift the material. |

| Features | High strength, the chain is tensile and wear-resistant, can withstand impact loads, and is resistant to high and low temperatures (≤300°C), making it suitable for harsh working conditions. However, maintenance costs are high, and chain replacement is complex. | Flexible structure, low operating noise, limited load-bearing capacity, unsuitable for high-temperature materials, low maintenance costs, and easy belt replacement. |

| Applicable Materials | Large, hard, abrasive, or high-temperature materials (300°C), such as ore, crushed stone (chunk size <100mm), coke, high-temperature slag, and limestone (medium to large chunks). | Powdered, small-particle, low-abrasive, room-temperature materials (not exceeding 120°C), such as flour, grain (particle size <20mm), cement powder, fertilizer powder, and fine chemical powder. |

| Lifting Height | Wide range, up to 60 meters or more, suitable for long-distance lifting. | Limited, generally <40 meters, suitable only for medium- and short-distance lifting. |

| Lifting Capacity | High throughput, typically 50-500 m²/h, with customizable models for higher throughput (suitable for high-capacity applications in large mines and heavy industry). | Medium throughput, typically 10-200 m²/h, not suitable for high-capacity applications. |

What are the structural components of a chain type bucket elevator?

A chain type bucket elevator primarily consists of a traction mechanism (chain/plate chain), a hopper for loading materials, a drive mechanism (which provides power to move the chain and bucket), an inlet, an outlet, and a casing.

What are the applications of the Chain Type Bucket Elevator?

The Chain Type Bucket Elevator is used in industries such as food, chemicals, building materials, mining, and agriculture to vertically lift powdered, granular, and bulk materials. These materials include grains, seeds, fertilizers, mined ore, coal, minerals, clinker, limestone, cement, chemical powders, abrasives, and sugar and flour used in food processing. It can lift various materials from low to high levels and is also suitable for lifting heavy, abrasive materials.

Chain Type Bucket Elevator Customer Case

| Application Scenario | Lifting Material | Lifting Capacity (m³/h) | Lifting Height (m) | Equipment Type |

| 600t/d Active Lime Production Line in Inner Mongolia | Limestone, active lime (crushed particle size ≤100mm, temperature ≤250°C) | 25 | 40 | TH chain bucket elevator |

| A large grain storage center in Europe | Wheat, corn (particle size ≤20mm, room temperature) | 5000 | 28 | TH chain bucket elevator |

| High-temperature oxidation pellet production line at a steel plant in China | High-temperature oxidation pellets (temperature ≤700°C, crush size ≤50mm) | 22 | 33 | NE Plate Chain Bucket Elevator |

Chain Type Bucket Elevator Manufacturer

Dahan Chain Type Bucket Elevators primarily offer chain and plate chain types. The chain utilizes both ring and plate chains, offering high tensile strength and tensile strength. Carbon steel and stainless steel housings are available, tailored to the material's particle size, moisture content, hardness, viscosity, and abrasiveness. The hoppers are available in food-grade plastic, stainless steel, and carbon steel. We offer a comprehensive range of models, with factory prices starting as low as $500. Both open and sealed configurations are available. We also offer customized solutions for diverse conveying needs, such as dust collectors, mobile configurations, and multi-point infeed/outfeed options.

Recommend Product

- Chain Type Bucket Elevator

- NE Plate Chain Bucket Elevator

- TH type chain bucket elevator

- TH Chain Bucket Elevator

- Belt Type Bucket Elevator