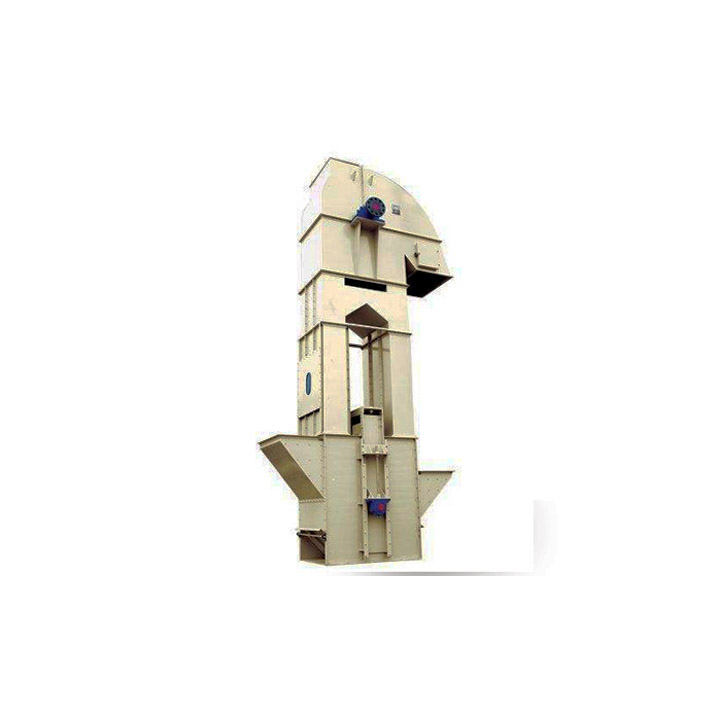

Vertical Bucket Elevator

Used for vertically lifting loose materials such as powder, granular and block materials, with material temperature ≤ 250℃

Conveying Capacity: 800m³/h

Conveying Height: 60 meters

Bucket Capacity: 3-50 liters

Bucket Speed: 0.5 m/s

Motor Power: 0.75-30 kW

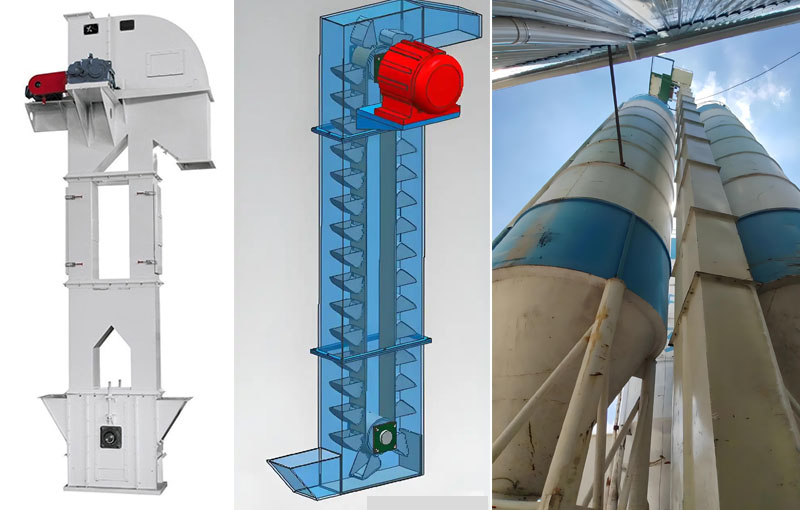

What is a Vertical Bucket Elevator?

Vertical Bucket Elevator is a device used to vertically lift various powders, granules and small pieces of bulk materials. It lifts materials vertically from a low place to a high place through a hopper. It is widely used in the building materials, chemical, metallurgy, grain and other industries. It is used to lift various bulk materials such as cement, coal, ore, grain, aggregates, fertilizers, etc. The lifting height can reach up to 80 meters, and the lifting capacity can range from 5 cubic meters to 800 cubic meters per hour depending on the model. Depending on the characteristics of the material (such as particle size, humidity, friction coefficient) and the conveying capacity, the hopper can be selected into deep bucket, shallow bucket and triangular bucket.

What are the advantages of a vertical bucket elevator?

The vertical bucket elevator features a simple structure, a small footprint, reliable operation, and easy maintenance. It utilizes inflow feeding, induction discharge, and a densely packed, high-capacity hopper arrangement. This eliminates backflow and scooping during material lifting. It can lift not only general powders and small granules, but also abrasive materials. It can deliver up to 800 cubic meters per hour and reach a lifting height of 60 meters. The tightly sealed casing ensures dust-free lifting.

What are the applications of the Vertical Bucket Elevator?

The Vertical Bucket Elevator can be used to vertically lift powdered, granular, non-sticky, dry materials with a bulk density of ≤1.3t/m³, such as cement, raw meal, clinker, crushed ore, fertilizer, plastic pellets, additives, rice, flour, feed, powdered sugar, coal powder, ore, slag, grain, bran, feed, chemical raw materials, capsules, and pills. The equipment is adaptable to the abrasiveness, density, and temperature of the material and can transport both lightly and heavily abrasive materials. Material temperatures generally must not exceed 250°C.

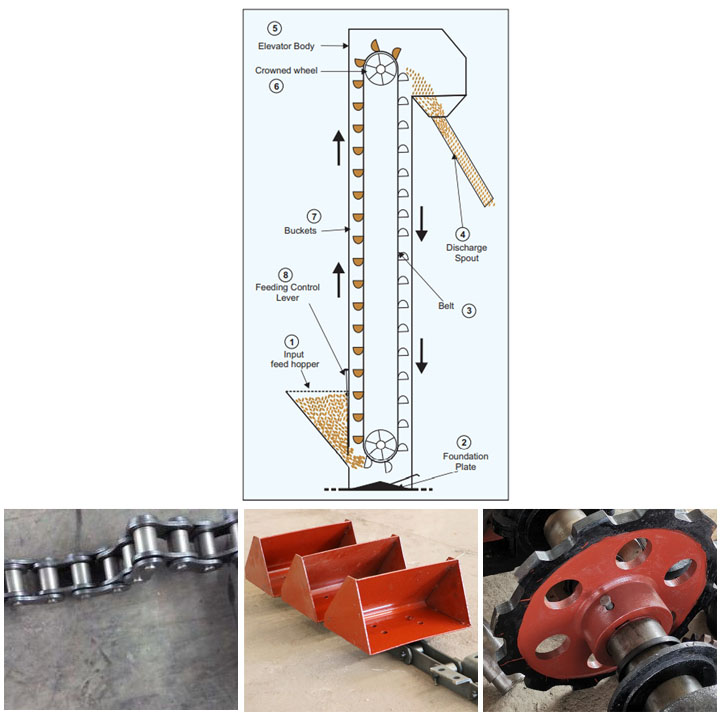

How does the Vertical Bucket Elevator work?

When the Vertical Bucket Elevator is activated, material enters the elevator from the inlet, is scooped up by the hopper, and is lifted vertically to the top along the conveyor chain until it is discharged at the outlet. The empty hopper then returns to the bottom at the other end to continue digging.

Vertical Bucket Elevator Models

| Model | Feed size MM | Bucket | Height m | Lifting capacity (m³/h) | Weight | ||

| Distance mm | Width MM | Capacity L | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | According to the specific vertical bucket elevator order total drawing verification to determine |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

|

Note: THE conveying capacity in the table is calculated according to the filling coefficient ψ-0.8 for reference only. |

|||||||

What are the structural components of a vertical bucket elevator?

A vertical bucket elevator consists of a housing, a traction member (conveyor chain), a hopper, a drive wheel (head wheel), a redirecting wheel (tail wheel), a tensioning device, a guide device, a feed port (inlet), and a discharge port (discharge port).

The traction member is a plate-type bushing roller chain. A single chain is fixed to the rear wall of the hopper, and a double chain is connected to each side of the hopper. A single chain is used for hopper widths of 160-250 mm, and a double chain is used for hoppers of 320-630 mm.

Cylindrical hoppers: Deep hoppers with a 65° angled opening and a large depth are used for conveying dry, fluid, and well-spread granular materials.

Shallow hoppers: A 45° angled opening and a shallow depth are used for conveying wet and fluid granular materials.

Deep hoppers are generally used for relatively dry and fluid materials.

Triangular hoppers: Materials are generally discharged in a directional, gravity-fed manner.

Pointed bucket: Its sidewalls extend beyond the base plate, forming ribs. During discharge, materials flow along the groove formed by the ribs and base plate. This bucket is suitable for transporting viscous and heavy bulk materials.

How much does a vertical bucket elevator cost?

The price of a vertical bucket elevator varies greatly depending on the model, configuration, and material, typically ranging from $450 to over $17,000. Key factors influencing price include: material (stainless steel is $150-$200+ more expensive than carbon steel), model and capacity (larger models with higher capacity are more expensive), lift height and drive power (higher height and greater power mean higher prices), and customized requirements (such as special hoppers, seals, or intelligent control systems). Specific pricing depends on your specific needs. Please contact our online customer service or email sales@xxdahan.com for details.

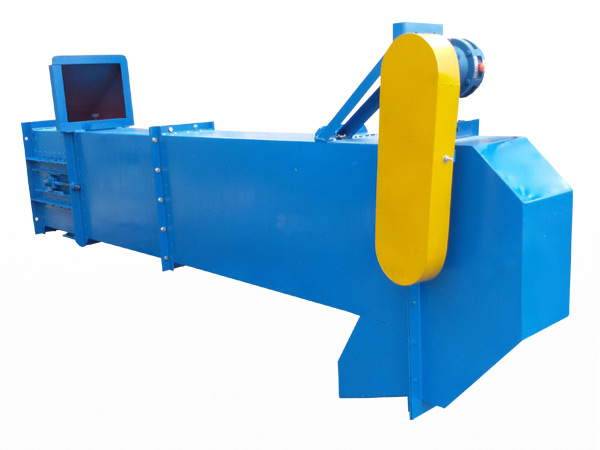

TH type chain bucket elevator

TH type chain bucket elevator