TB Bucket Elevator

The plate sleeve roller chain is used as the traction component. The buckets are fixed on the chain plates and arranged continuously. The bucket elevator uses inflow loading and low-speed heavy-load unloading. It can lift various bulk materials, from light to heavy, from fine to large pieces.

| Lifting height | 3 - 45 m |

| Lifting capacity | 800 cubic meters/hour |

| Hopper material | Plastic, stainless steel, high manganese steel, etc. |

| Material temperature | ≤250℃ |

| Applicable materials | powder, granular and block materials |

| Select type | carbon steel stainless steel |

What is TB Bucket Elevator?

TB Bucket Elevator is an efficient equipment for vertical conveying of granular, powdery or small block materials. It is widely used in grain, chemical, building materials, metallurgy and other industries. It can lift materials from low to high to meet the continuous conveying needs of production lines. TB Bucket Elevator has become one of the indispensable conveying equipment in modern industry with its high load-bearing capacity, stability and energy-saving characteristics.

What are the characteristics of TB Bucket Elevator?

TB bucket elevator has low energy consumption. Compared with traditional chain elevator, its energy consumption for lifting materials of the same height is only 1/3~1/2 of that of chain elevator.

It adopts hardened gear reducer and high-quality alloy steel high-strength plate chain, with high transmission efficiency and stable operation.

It can convey medium and large bulk materials with loose density <2t/m³, including abrasive materials (such as lump coal, crushed stone, ore, coke, etc.) with a temperature not exceeding 250℃.

The whole machine adopts a fully sealed structure to effectively prevent dust leakage. The casing adopts a ribbed structure with good rigidity and high precision.

It can be used for powdery, granular, bulk and abrasive materials. The lifting height is 5m-60m, the conveying capacity is 20 to 560m³/h, and it can lift 60mm-150mm bulk materials.

How does TB Bucket Elevator work?

TB Bucket Elevator uses hoppers evenly installed on the traction structure to scoop materials from the feed port below, transport them upward along the transmission device, and unload them by centrifugal force or gravity when they reach the top, thus realizing vertical transportation of materials.

TB Bucket Elevator Parameters

| Model | Maximum feed size mm | Hopper | Lifting height m | Maximum lifting capacity (cubic meters/h) | Motor power Hoist weight | ||

| Bucket distance mm | Width MM | Capacity L | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | Determined according to the specific vertical bucket elevator order general drawing |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

|

Note: The maximum conveying capacity in the table is calculated based on the filling factor ψ-0.8, for reference only. |

|||||||

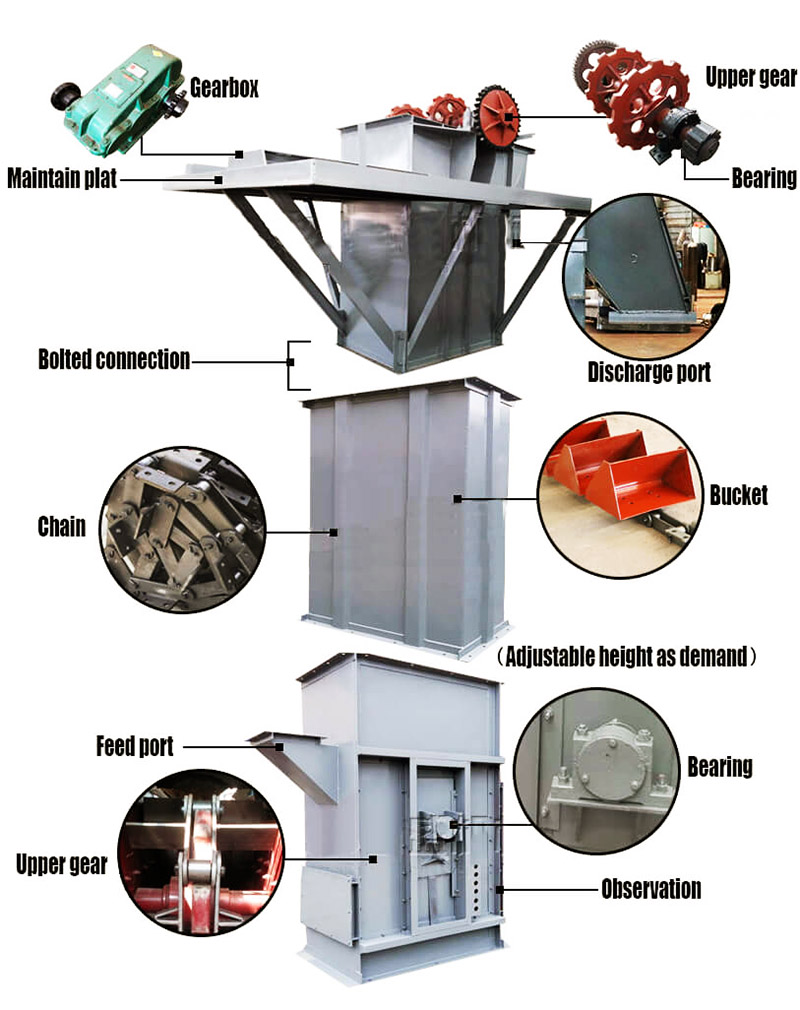

What are the structures of TB Bucket Elevator?

Traction device: including traction belt or chain, used to drive the bucket to move.

Hopper: used to load materials, the material can be high-strength plastic or iron.

Drive device: provides power, usually equipped with motor and reducer.

Tension device: adopts gravity tensioning to ensure the stability of the traction belt or chain.

Casing: sealed design to prevent dust leakage

What are the applications of TB Bucket Elevator?

The TB bucket elevator is widely used for vertical lifting of bulk materials in industries such as cement, mining, metallurgy, chemical, power, and building materials. It is especially suitable for handling large-sized, abrasive, and high-temperature materials. Typical materials lifted by the TB bucket elevator include limestone, coal, cement clinker, sand, gravel, gypsum, slag, fertilizer, and various ores. Its strong structure, wear-resistant chains, and high-capacity design make it ideal for transporting heavy, granular, or powdery materials efficiently and reliably over significant heights.

TB Bucket Elevator Customer Case

| Application scenario | Lifting material | Lifting height | Lifting amount |

| Lime powder production enterprises transport powder from the ground to the storage tank to meet the subsequent packaging or mixing process. | Lime powder | 12 meters | 20 tons per hour |

| Cement plants use it to transport clinker to batching silos to ensure stable feeding of production lines. | Cement clinker | 25 meters | 50 tons per hour |

| Grain processing plants transport raw materials to cleaning screens or storage silos to achieve automated grain processing. | Rice, wheat | 8 meters | 30 tons per hour |

| Glass manufacturing plants and construction industries achieve efficient material transportation. | Fine sand, quartz sand | 15 meters | 40 tons per hour |

How much does a TB Bucket Elevator cost?

The price of a TB bucket elevator varies depending on several factors. Material choice plays a major role: carbon steel is the standard, cost-effective option for general industrial use, while stainless steel, required for high hygiene or corrosion-resistant environments like food or chemical industries, typically costs 30%–50% more. Height also affects pricing, with each additional meter adding approximately $150–$300, depending on structural and motor capacity needs. Special features such as explosion-proof motors can increase the base price by 15%–30%, and a variable frequency drive (VFD) for speed control can add another $500–$1,500. Customizations like special buckets made of nylon, polyurethane, or stainless steel, as well as additional designs for dustproofing, anti-corrosion coatings, or extra sensors, can significantly raise the overall cost.

|

TB250 (Small Size) |

TB400 (Medium Size) |

TB630 (Large Size) |

|

Height: 6-12 meters |

Height: 10-20 meters |

Height: 15-30 meters |

|

Capacity: 15-30 tons/hour |

Capacity: 30-60 tons/hour |

Capacity: 60-100 tons/hour |

|

Price Range: $1,500 - $3,000 |

Price Range: $3,000 - $6,000 |

Price Range: $6,000 - $10,000 |

NE Plate Chain Bucket Elevator

NE Plate Chain Bucket Elevator GTD Bucket Elevator

GTD Bucket Elevator