Small mobile elevator

Solve various material lifting needs in short distances and small ranges in various scenarios.

| Lifting height | 5-20 meters |

| Conveying capacity | 10-50 t/h |

| Hopper capacity | 2-10 L |

| Motor power | 1.5-7.5 kW |

| Movement | With wheels or removable base |

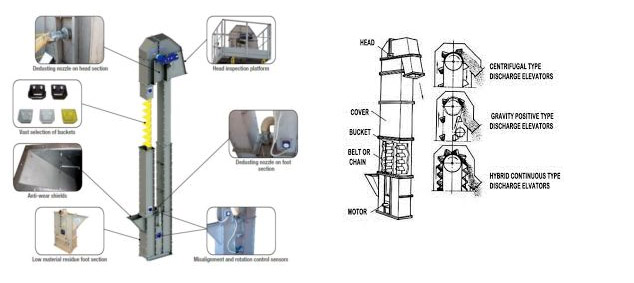

What is a Small mobile elevator?

Small Mobile Elevator is a vertical material conveying equipment designed for small working scenes. It combines the vertical conveying capacity of a bucket elevator with the flexibility of a mobile device, and is suitable for occasions that require frequent movement or limited space. Compared with traditional fixed bucket elevators, small mobile bucket elevators are small in size, light in weight, easy to install and move, and are widely used in agriculture, food, chemical industry, construction and other industries.

What types of Small Mobile Elevators are there?

| Type | Applicable materials | Lifting height | Lifting amount | Features of traction device | Typical application scenarios |

| Belt type | Lightweight particles/powder | ≤10 meters | 5~50 m³/h | Rubber belt or high-strength fiber belt, with baffles or side guards on the belt surface. | Temporary transportation in agriculture and food processing |

| Chain type | Medium block/wear-resistant material | ≤15 meters | 10~100 m³/h | Metal chain (such as roller chain, bent plate chain), batching hopper or hook. | Construction and mining material transfer |

| Plate chain | Heavy/high temperature/abrasive materials | ≤20 meters | 30~200 m³/h | Heavy plate chain (such as NE type chain), equipped with metal hopper. | Heavy-duty handling in metallurgy and cement industry |

| Z-type | Regularly packaged items | ≤6 meters | 5~30 m³/h | Chain or belt, materials are transported horizontally-vertically-horizontally in a "Z"-shaped path. | Handling in warehouses and production lines with limited space |

What are the advantages of Small Mobile Elevator?

Small size and light weight: suitable for working environments with limited space, easy to transport and install.

Strong mobility: equipped with wheels or detachable base, easy to transfer quickly between different work locations.

High efficiency and energy saving: adopts inflow feeding and induction unloading design to reduce material return and invalid power.

Good sealing: reduce dust flying, suitable for industries with high requirements for environmental hygiene, such as food and medicine.

Easy operation: usually equipped with intelligent control system, supporting one-button start and fault diagnosis.

How does Small Mobile Elevator work?

A Small Mobile Elevator works by continuously loading material into buckets on a motorized belt or chain, elevating it along a curved path, and discharging it at the top—all mounted on a mobile platform for flexible positioning.

Small Mobile Elevator parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

What are the applications of Small Mobile Elevator?

Agriculture: used for vertical transportation of grain and feed.

Food industry: conveying powdery or granular materials such as flour, sugar, and grain.

Chemical industry: conveying fertilizers, plastic particles, etc.

Construction industry: used for short-distance lifting of cement and sand and gravel.

Pharmaceutical industry: conveying pharmaceutical raw materials to meet hygiene requirements.

Small Mobile Elevator customer case

| Case | Grain processing enterprise | Fertilizer production plant | Construction site |

| Case description | A grain processing enterprise needs to lift grain from the ground to a 15-meter-high storage bin. Traditional fixed elevators cannot meet the needs of frequent movement, so a small mobile bucket elevator was selected. The equipment adopts a belt-type design, which is suitable for light granular materials, with high lifting efficiency and good dust control. By using this equipment, the company has improved its operating efficiency by 30% and reduced the cost of manual handling. | A fertilizer production plant needs to lift high-temperature fertilizer granules from the production line to the packaging workshop. Due to the high temperature of the material (about 50°C), the company chose a small chain-type mobile elevator. The equipment is resistant to high temperatures and operates stably, successfully solving the problem of high-temperature material transportation. The equipment is flexible and can be quickly adjusted according to production needs, significantly improving the flexibility of the production line. | A construction site needs to frequently transport cement and sand and gravel between different construction areas. Due to limited site space and the need to quickly move equipment, the site uses a small mobile bucket elevator. The equipment is equipped with a detachable base for easy transfer between different areas. By using this equipment, the construction site reduced material handling time and improved construction efficiency. |

| Lifting materials | Grains (wheat, corn) | Fertilizer granules | Cement and sand |

| Lifting capacity | 20 tons/hour | 15 tons/hour | 10 tons/hour |

| Lifting height | 15 meters | 10 meters | 8 meters |

| Application site | Transfer between grain storage warehouse and processing workshop | Connection area between fertilizer production line and packaging workshop | Temporary material storage area and construction area of construction site |

How to select Small Mobile Elevator?

| Considerations | Segmentation dimensions | Selection recommendations |

| 1. Material properties | Powdered materials (flour, cement) | Belt elevator, avoid dust |

| Granular materials (grain, fertilizer) | Belt or light chain hoist | |

| Heavy/abrasive materials (ore, coal) | Wear-resistant chain or plate chain hoist | |

| High-temperature materials (chemical raw materials) | High-temperature resistant chain or plate chain hoist | |

| Material humidity | Rust-proof materials (such as stainless steel) should be used for wet materials | |

| Material fluidity | Use large-capacity hoppers for materials with poor fluidity | |

| 2. Lifting height | Low height (≤ 10 meters) | Suitable for low-power, small and lightweight designs |

| Medium height (10-20 meters) | Choose a more stable structure, such as a reinforced chain or belt | |

| Ultra-high height (> 20 meters) | It is recommended to choose a heavy chain or plate chain hoist to ensure stability | |

| 3. Lifting capacity | Smaller conveying capacity (≤ 10 tons/hour) | Suitable for small hoppers (2-5 liters), lower operating speed |

| Medium conveying capacity (10-30 tons/hour) | Choose a medium-sized hopper (5-10 liters), moderate operating speed | |

| Larger conveying capacity (> 30 tons/hour) | It is recommended to choose a large-capacity hopper (≥ 10 liters), higher operating speed | |

| 4. Hopper material | Ordinary carbon steel | General material, low cost, not corrosion resistant |

| Stainless steel | Food, medicine and other industries, corrosion resistant, easy to clean | |

| Wear-resistant steel | Abrasive materials (ore, coal), extended life | |

| Plastic or nylon | Lightweight, non-corrosive material, light weight, low noise |

Small Bucket Elevator

Small Bucket Elevator Small Pipe Spiral Elevator

Small Pipe Spiral Elevator