Small Bucket Elevator

It is used to lift materials vertically from low to high places with limited space and small conveying volume. It is the preferred vertical conveying solution for users with small production volume. The price range is $350.00-$5,500.00

| Lifting height | 5-20 meters |

| Conveying capacity | 0.5-20 m³/h |

| Hopper capacity | 2-10 L |

| Motor power | 1.5-7.5 kW |

| Movement | With wheels or removable base |

What is Small Bucket Elevator?

Small bucket elevator is a device used for conveying small amounts of materials. It is often used to vertically lift small or bulk materials. The material is lifted from a low location to a high location through a hopper fixed to a belt or chain. The lifting height can reach 20 meters, and the lifting capacity is 0.5-20 cubic meters per hour. Its small size, light weight, and flexible movement make it suitable for occasions with limited space or frequent movement, meeting the material conveying needs of small and medium-sized enterprises.

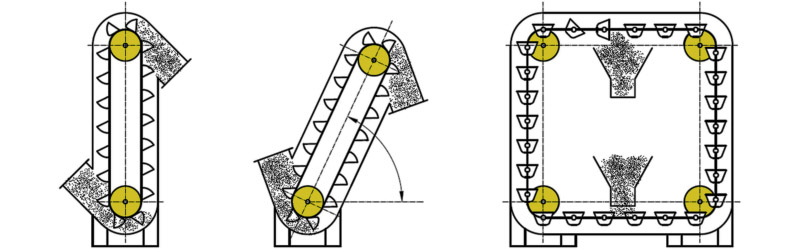

What are the types of Small Bucket Elevators?

Small bucket elevators can be divided into four types: fixed, plate chain, mobile, and suspended. You can choose the appropriate model according to the lifting material and application scenario.

Fixed Small bucket elevator: This type of bucket body is fixedly installed on a conveyor chain or conveyor belt, with a simple structure, suitable for stable and continuous material conveying.

Tipping Small bucket elevator: It adopts an automatic tipping bucket design. The bucket body tipped over when it reaches the unloading area, which can quickly realize material unloading and is suitable for occasions with high unloading requirements.

Mobile Small bucket elevator: It is installed on a mobile platform with wheels or tracks, which is convenient for mobilization between different workplaces and suitable for application scenarios with changing site conditions.

Suspended Small bucket elevator: The bucket body is driven and lifted by suspension, which is suitable for applications with customized requirements for conveying trajectory and unloading methods under special working conditions.

Small bucket elevator model

| Model | TD160 | TD400 | NE15 | TH315 |

| Pictures |

|

|

|

|

| Bucket width (mm) | 160 | 400 | 150 | 315 |

| Hopper volume (L) | 0.5 - 1.9 | 3.1 - 9.4 | 2.5 | 6 |

| Bucket speed (m/s) | 1.4 | 1.8 | 0.5 | 1.4 |

| Lift amount (m³/h) | 5.4 - 16 | 24 - 66 | 15 | 60 |

What are the advantages of small bucket elevators?

Small bucket elevator is a device that does not require a large conveying volume to lift materials. It is small in size and has moving wheels at the bottom. It is flexible and has a wide range of adaptability. It can lift powder, granular, and bulk materials.

Miniaturization and flexibility: compact size, easy to install and move in a small space;

High efficiency and energy saving: adopts advanced drive system, low energy consumption and high efficiency;

Gentle conveying: Continuous or slow operation is adopted to reduce damage to fragile materials.

Good sealing: The closed structure effectively reduces dust pollution and improves the safety of the working environment.

What is the small bucket elevator theory?

When the Small Bucket Elevator is working, the circulating bucket body driven by the motor automatically loads, continuously lifts and unloads along the fixed track to realize the vertical transportation of materials.

Loading: The material is evenly loaded into the lifting bucket from a low place;

Lifting: The driving motor drives the conveying device to lift the bucket body step by step along the curved track;

Unloading: When the lifting bucket reaches the set height, it automatically unloads by gravity or mechanical action and transports the material to the designated area.

Small Bucket Elevator Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

What are the structures of Small Bucket Elevator?

Small Bucket Elevator consists of a running part, a driving device, an upper device, a middle shell, a lower device, etc.

Operating parts - consisting of hopper and special plate chain, NE30 and single-row chain are used under NE50-NE800, double-row chain is used under NE30.

Driving device - Drive by multiple driving combinations (depending on the actual needs of users). The driving platform is equipped with overhaul racks and railings. There are two kinds of driving devices, left and right.

The upper device is equipped with rails (double-row chains), backstops and discharge outlets equipped with anti-recycling rubber plates.

Mid-section - Some mid-sections are equipped with rails (double chains) to prevent chains from swinging.

Bottom device - automatic tensioning device is installed.

What are the applications of Small Bucket Elevator?

Small bucket elevators are widely used in a variety of industries and are suitable for lifting free-flowing materials in granular, powdered and small pieces. In the field of food processing, it can be used to transport rice, wheat, sugar, coffee beans, milk powder, nuts, candy, puffed food, etc., to ensure that the materials remain intact and hygienic during the transportation process. In agriculture, it is suitable for lifting grains, seeds, feed, etc. to meet the vertical transportation needs of agricultural products. In the chemical and building materials industries, it can be used to transport lime, gypsum, fly ash, ore, fertilizer, plastic granules and other materials. In addition, small bucket elevators are also suitable for conveying materials such as wood chips, animal feed, and mineral sand. It should be noted that it is not recommended to convey wet, sticky or mud-like materials to avoid problems such as poor discharge and equipment blockage.

Small Bucket Elevator Customer Case

| Application scenario | Lift height | Lifting capacity | Features |

| Grain processing plant - used for wheat processing production line to lift wheat from the ground to the storage silo. | 5 meters | 5 tons/hour | Use wire rope belt bucket elevator to reduce material crushing rate, equipped with dust cover to avoid dust spillage, in line with food industry hygiene standards |

| Fertilizer plant - used for fertilizer production line, lifting granular fertilizer to mixing equipment. | 8 meters | 8 tons/hour | Wear-resistant hopper design, suitable for corrosive materials, PLC control, automatic start and stop, reduce manual intervention |

| Building materials plant - used to lift cement powder from storage tank to packaging machine. | 6 meters | 6 tons/hour | Fully enclosed structure to prevent dust explosion risk, equipped with tension adjustment device to ensure stable belt operation |

Small mobile elevator

Small mobile elevator Small Pipe Spiral Elevator

Small Pipe Spiral Elevator