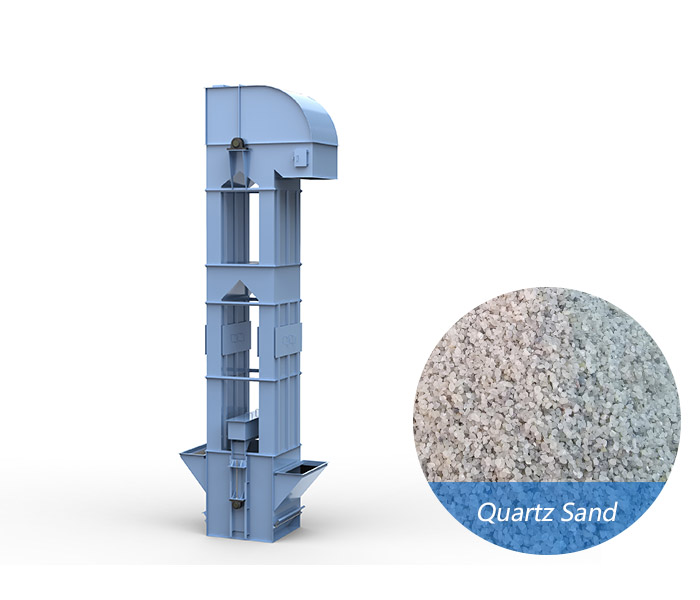

Sand Bucket Elevator

A sand elevator used to vertically lift sand, quartz sand, silica sand, aggregate and other materials vertically from a low place to a high place. The price range is: $400.00-$6,800.00

| Sand particle size | 4-180 (mm) |

| Lifting amount | 25-148m³/h |

| Lifting height | 60 meters |

| Lifting speed | 1.4-2 meters/second |

| Material | Carbon steel, stainless steel |

What is Sand Bucket Elevator?

Sand Bucket Elevator is an elevator that vertically lifts bulk materials such as sand through a hopper. It can lift sand from the stockpile area to a designated location with a lifting height of up to 60 meters and a lifting capacity of 2-200 tons per hour. It can be used to lift various types of sand, including dry sand, quartz sand, river sand, sea sand, fine sand, silica sand, and aggregates. Shallow buckets, deep buckets, or triangular buckets can be selected according to the type of sand to be lifted to meet the lifting needs of sand with different particle sizes and fluidity. We generally do not recommend using bucket elevators for wet sand that is highly sticky and easily adhered. If you want to use one, you can choose a hopper with an anti-sticking design or pre-treat the sand to reduce its humidity to ensure lifting efficiency.

What types of Sand Bucket Elevator are there?

Sand Bucket Elevator mainly has three types: Z type, TH/TD type, and NE type. You can choose the appropriate model according to the type and fluidity of the sand to be lifted and the application scenario. We can also customize the lifting plan for you according to your needs.

Z-Type Sand Bucket Elevator: It can lift dry, free-flowing sand to a height of up to 30 meters, with a lifting capacity of 6-50 m³/h. It is often used in situations where a combination of horizontal and vertical sand conveying is required, and multiple unloading points are possible.

TH/TD Chain Sand Bucket Elevator: It can lift dry, free-flowing sand to a height of up to 30 meters, with a lifting capacity of 6-50 m³/h. It is often used in situations where a combination of horizontal and vertical sand conveying is required, and multiple unloading points are possible.

NE Type Plate Chain Sand Bucket Elevator: Commonly used for conveying quartz sand, with the largest conveying capacity, it can be used for medium and large pieces and sand materials with certain abrasiveness, with a lifting height of up to 60 meters and an hourly conveying capacity of 15-800 m³/h

What is the purpose of the Sand Bucket Elevator?

The Sand Bucket Elevator is primarily used for lifting various types of sand and gravel in sand pits, construction companies, foundries, aggregate sand and gravel production plants, and concrete mixing plants. It lifts sand and gravel vertically to a specific height into a storage silo. It is commonly used for materials such as quartz sand, foundry sand, ceramsite sand, high-temperature sand, river sand, sea sand, and fine sand. For materials with a certain degree of moisture, such as wet sand or highly viscous molding sand, a machine with a deep or special anti-sticking hopper (such as the TH chain type) should be selected, and the lifting speed should be reduced to prevent sticking and incomplete discharge.

What are the advantages of Sand Bucket Elevator?

The Sand Bucket Elevator can transport sand vertically. It occupies a small area and is suitable for production environments with limited space. It has a processing capacity of up to 200 tons/hour and a lifting height of up to 60 meters, which meets the needs of large-scale sand and gravel transportation. Different hoppers can be selected for different types of sand to ensure that sand is not easily spilled during transportation, reducing waste. A sealing cover or dust removal system can also be selected as needed to reduce dust leakage and improve the working environment.

How does the Sand Bucket Elevator work?

The sand bucket elevator lifts sand from the bottom feed port to the top discharge port through a continuously circulating hopper. The hopper is fixed on a transmission belt or chain. As the transmission device operates, the hopper loads sand from the bottom, unloads the sand to the designated location after passing through the top drive wheel, and then returns to the bottom, repeating the cycle to achieve continuous transportation.

Sand Bucket Elevator Parameters

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

Sand Bucket Elevator Customer Case

| Application scenario | Lift height | Lift capacity | Features |

| A large cement plant needs to transport silica sand from the ground to a 30-meter-high raw material warehouse for cement batching. | 30 meters | 120 tons/hour | Wear-resistant deep bucket (to prevent silica sand wear), dust-proof seal design (to reduce dust emission), variable frequency speed regulation (to adapt to different production needs) |

| A certain automotive parts foundry needs to lift the foundry sand from the underground recovery pit to the regeneration system. | 15 meters | 60 tons/hour | Non-magnetic chain plate design (to avoid metal debris adsorption), removable wear-resistant lining (for easy cleaning and maintenance), emergency brake device (to prevent sudden shutdown and backflow) |

| A certain quartz sand processing plant needs to lift the high-temperature dry sand (200°C) from the dryer outlet to the grading screen. | 25 meters | 180 tons/hour | Heat-resistant steel bucket (304 stainless steel) (resistant to 300°C), high-temperature chain lubrication system (automatic oil filling, anti-jamming), air-cooled motor (to avoid overheating shutdown) |

Frequently Asked Questions about Sand Bucket Elevator

How much does a sand bucket elevator cost?

The price of a sand bucket elevator is affected by various factors, including model, lifting capacity, lifting height, material, and customization requirements. It typically ranges from $400 to $6,800. Please contact our online customer service for a detailed quote based on your needs.

What are the main functions and uses of a sand bucket elevator in sand handling?

Its primary function is to transport sand vertically at high altitudes and with high efficiency. Common applications include conveying aggregates for concrete batching plants and dry-mix mortar production lines; conveying molding sand in foundries; and feeding and transferring materials during process operations in glass factories and building materials plants.

How do I choose the right hopper for a sand bucket elevator?

When choosing a hopper for a sand bucket elevator: For sand, a deep hopper (ZH type) or a shallow hopper (SH type) is generally recommended. Their spaced arrangement facilitates material throwing and provides a high fill rate.

Material: Due to the abrasive nature of sand, hoppers made of wear-resistant steel (such as MN13) or galvanized steel must be selected to extend their service life.