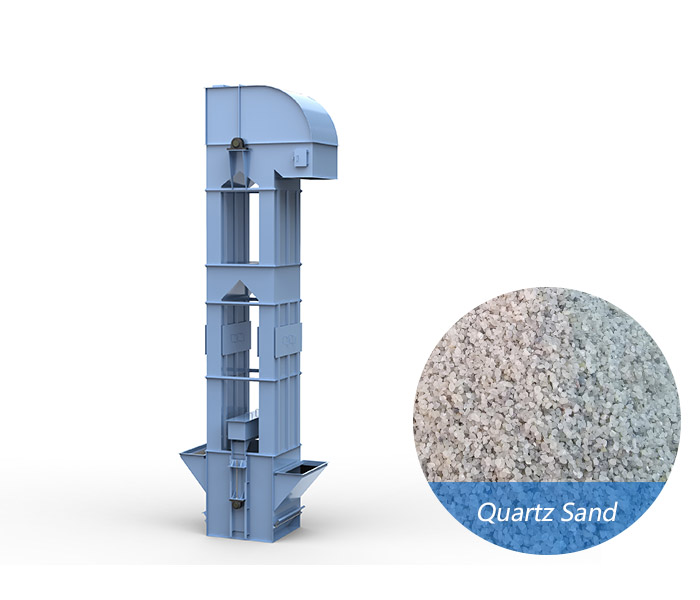

Quartz sand bucket elevator

A hoist that can transport quartz sand vertically from the ground to a high place; the price of each hoist ranges from $350 to $6800, and the specific price is related to the material, model, lifting height, and customization.

| Lifting height | 10-80 m, Can be customized according to needs |

| Conveying capacity | 10-300 t/h |

| Hopper capacity | 5-50 L |

| Motor power | 5.5-75 kW |

| Operating speed | 0.8-3.5 m/s |

What is Quartz Sand Bucket Elevator?

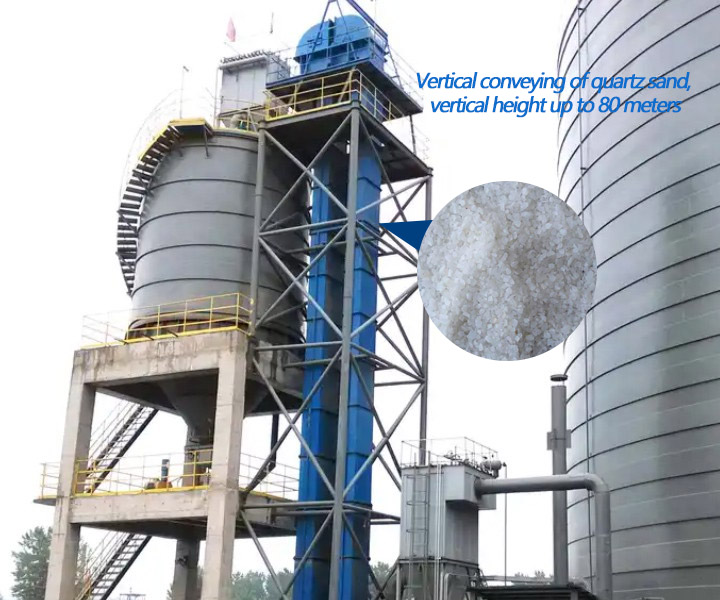

Quartz sand bucket elevator is a continuous elevator used for feeding, batching, and vertically conveying quartz sand between process steps. It uses a drive mechanism to drive the hopper to lift quartz sand from a low position to a high position. It can lift dry, non-sticky powdered (0-5mm), granular (5-30mm), and small-lump (≤50mm) quartz sand, including various mineral sands with medium to low abrasiveness. It has a lifting height of 3-60 meters and a maximum lifting capacity of 800 tons per hour.

Quartz sand bucket elevators can also transport wet, sticky quartz sand, but we need to choose a plate chain bucket elevator. A deeper, larger-capacity hopper can prevent sticking. For quartz sand containing corrosive components, we can choose a PP plastic hopper. Therefore, when choosing, be sure to select the appropriate equipment based on the properties of the quartz sand.

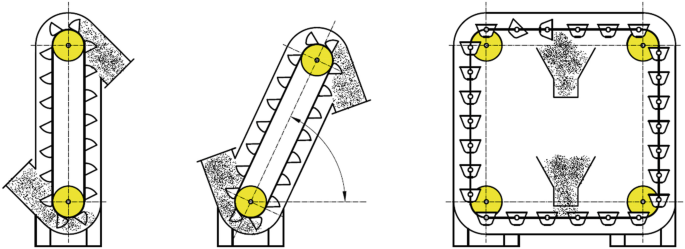

What are the types of Quartz sand bucket elevators?

| Type | Vertical bucket elevator | Z-type bucket elevator |

| Picture |

|

|

| Applicable quartz sand type | - Dry powder to small pieces (0.1-50mm), good fluidity, moisture content <5% | Powder to medium block (0.1-30mm), can handle slightly sticky materials, moisture content <8% |

| Lifting height range | 4.8-40 meters (single point vertical) | 3-15 meters (multi-stage turning) |

| Typical conveying capacity | 8-900m³/h (TH450 type up to 69m³/h) | 5-200m³/h (limited by turning point) |

| Application scenario | Long-distance vertical transportation of high-purity quartz sand, glass/photovoltaic raw material production lines, centralized lifting of large mines | Multi-layer transportation with limited plant space, process layout that requires changing direction, small and medium-sized quartz sand processing plants |

| Hopper design | Deep hopper (S type)/shallow hopper (Q type), large spacing (300-640mm), stainless steel/wear-resistant steel material | Special corner hopper, small spacing (200-400mm), with guide wing design to prevent spillage |

| Sealing | Fully enclosed, dust leakage <5mg/m³ | Special sealing is required at the turning point, and dust control is slightly weaker |

| Equipment footprint | Small footprint (vertical space only) | Horizontal + vertical composite occupancy |

| Typical models |

TH160/TH250/TH350 (chain) TD315/TD500 (belt) |

ZT150/ZT300 (Special Z type) |

How to select Quartz Sand Bucket Elevator?

When choosing a quartz sand bucket elevator, you need to consider the particle size, abrasiveness and water content of the quartz sand; determine the lifting height and lifting amount, and finally select the material and determine the use environment.

Analyze Quartz Sand Characteristics: Quartz sand's particle size, moisture content, corrosiveness, and temperature characteristics directly influence the selection of a quartz sand bucket elevator. For dry quartz sand (20 mesh ~ 5mm), a standard bucket elevator (such as the TD or TH models) is suitable. For ultrafine powders (<100 mesh), a sealed, dust-proof design (such as the TDTG model) is recommended to reduce dust. For conveying high-temperature quartz sand (>80°C), a high-temperature-resistant chain (such as the TH model) or a heat-resistant hopper (stainless steel or manganese steel) is required. For corrosive quartz sand (such as pickled quartz sand), a stainless steel (304/316) or polyethylene (PP) hopper and casing are recommended. For conveying highly viscous or high-moisture quartz sand, a screw conveyor is recommended.

Determine Lifting Height & Capacity: The lifting height and lifting capacity of a Quartz sand bucket elevator are also key parameters in selecting a model. For lifting heights within 15 meters and lifting capacities within 50 tons, we can choose a belt bucket elevator; for lifting heights between 10-30 meters and lifting capacities between 10-100 tons, we can choose a chain bucket elevator; for lifting heights above 30 meters and lifting capacities exceeding 200 tons, we can choose a plate chain bucket elevator. If horizontal and vertical conveying is required, our Z-type bucket elevator can be selected.

Select Material & Construction: Quartz sand bucket elevator hoppers are available in a variety of materials, including Q235 carbon steel, 304/316 stainless steel, manganese steel/heat-resistant steel, and high-molecular polyethylene (PE). The appropriate hopper can be selected based on the properties of the quartz sand being transported. We can also customize hoppers with dust-proof, high-temperature-resistant, and anti-stick properties to meet customer needs.

How does the quartz sand bucket elevator work?

Quartz sand bucket elevator introduces quartz sand through the bottom feed port, and uses the hopper installed on the vertical or inclined annular traction member to lift the quartz sand to the top driven by the driving device, and unloads it by gravity or centrifugal force. The empty hopper is recycled back to the bottom to achieve continuous vertical transportation of quartz sand.

Quartz Sand Bucket Elevator Model

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

What are the functions of quartz sand bucket elevator?

Quartz sand is a hard and wear-resistant material. Ordinary conveying equipment is prone to wear, low efficiency and high maintenance cost. Our quartz sand bucket elevator is designed to solve these problems and has the following core advantages:

Vertical conveying: Lifting quartz sand from low to high, up to 60 meters.

Continuous operation: Suitable for production lines that require continuous conveying.

Reduce dust: Adopt multi-layer labyrinth seal + air curtain dust prevention technology to ensure dust leakage <2mg/m³, which is far lower than the national standard (10mg/m³)

Strong wear resistance: Wear-resistant materials are used to adapt to the high wear characteristics of quartz sand.

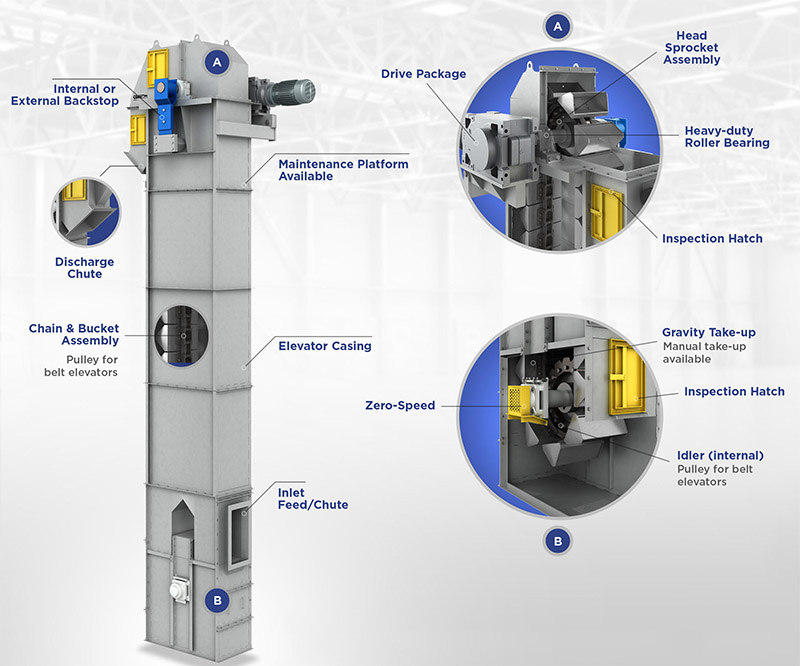

What structures does the quartz sand bucket elevator consist of?

Quartz sand bucket elevator consists of head/tail device, hopper assembly, drive device and casing.

Head device: including drive wheel, backstop and discharge port.

Tail device: including tension wheel and self-cleaning structure to prevent material adhesion.

Hopper: high-strength plastic or iron hopper, wear-resistant and large capacity.

Chain or belt: used to fix and drive the hopper.

Shell: sealed design to reduce dust leakage.

What are the applications of quartz sand bucket elevator?

Quartz sand bucket elevators are commonly used in quartz sand production lines, glass manufacturing, foundry, chemical and water treatment industries to lift crushed raw materials to screening machines, storage silos or mixing equipment. The following are related application scenarios:

Glass manufacturing industry: used for the transportation of quartz sand raw materials.

Casting industry: Convey quartz sand for casting.

Chemical industry: used for vertical lifting of chemical raw materials.

Building materials industry: transporting quartz sand for the production of tiles, ceramics, etc.

Water treatment industry: used for the transportation of quartz sand for filtration.

Quartz Sand Bucket Elevator Customer Cases

| Application Scenario | Amount of improvement | Raise height | Features |

| Vertical lifting of raw quartz sand from ground storage to the washing and screening line. | 50 tons/hour | 15 meters | Stainless steel buckets to prevent contamination, sealed design to reduce dust |

| Transporting high-purity quartz sand to the glass melting furnace. | 80 tons/hour | 20 meters | Food-grade material construction, wear-resistant chains for long-term use |

| Feeding quartz sand into molding machines for metal casting. | 30 tons/hour | 10 meters | Heavy-duty design for abrasive sand, easy maintenance access points |

| Elevating filter-grade quartz sand to packaging and distribution lines. | 20 tons/hour | 8 meters | Gentle handling to prevent particle breakdown, corrosion-resistant frame |

Quartz sand bucket elevator manufacturer

Xinxiang Dahan is a leading manufacturer of Quartz sand bucket elevators. We offer a variety of models, including TD, TH, NE, and Z, to meet diverse conveying needs. With lifting heights ranging from 5 to 60 meters and a conveying capacity of 5 to 800 tons/hour, we meet the vertical conveying needs of various types of quartz sand (dry powder, granules, and small lumps). The equipment is constructed of 304 stainless steel, wear-resistant manganese steel, and plastic-sprayed carbon steel, offering corrosion and wear resistance. Customizable designs are available, including hopper shape (deep, shallow, or sharp-angled), sealing level (dustproof, airtight), and drive mode (variable frequency, explosion-proof). We can customize the material, application, and product based on your needs, flexibly adapting to meet customer production line requirements.