Organic Fertilizer Conveying Bucket Elevator

It can be used to lift organic fertilizer vertically or inclined from a low place to a high place during the production, processing and storage of organic fertilizer. The price ranges from $400.00 to $9,600.00.

| Lifting height | 5-80 meters, customized according to specific needs. |

| Conveying capacity | 5-500t/h |

| Hopper capacity | 5-20L |

| Motor power | 2.2-7.5 kW |

| Material | carbon steel, stainless steel, etc. |

| Applicable materials | organic fertilizer, chemical fertilizer, compound fertilizer, feed and other abrasive, grinding and grinding powders, granules and small pieces |

What is Organic fertilizer conveying bucket elevator?

The organic fertilizer conveying bucket elevator is a type of elevator used for the vertical conveyance of various types of organic fertilizers, such as compost, pellets, and biowaste. It lifts organic fertilizer from a low location to a high location via a hopper fixed to a belt or chain. The lifting height ranges from 3 to 60 meters, and the lifting capacity ranges from 5 to 500 tons per hour. It is commonly used in the production, processing, packaging, and storage of organic fertilizers.

Organic fertilizers typically include compost, bio-organic fertilizers, and livestock and poultry manure. These materials are sticky, corrosive, and contain a certain amount of moisture, requiring specialized conveying equipment. Organic fertilizer conveying bucket elevators offer three hopper options tailored to the characteristics of organic fertilizers: a deep hopper (suitable for dry powdered or granular organic fertilizers), a shallow hopper (for less sticky materials), and a pointed bottom hopper (for easy unloading and anti-sticking). Materials include stainless steel, carbon steel, and plastic (PP/PE).

How to choose a bucket elevator for different types of organic fertilizers?

Organic fertilizers come in powdery, granular, wet, sticky, and high-temperature forms. When selecting an organic fertilizer conveying bucket elevator, you need to consider the material characteristics, lifting height, and conveying capacity.

For powdered organic fertilizers (such as fermented compost): we recommend the TD belt bucket elevator (lifting height ≤ 40m, conveying capacity 16-395m³/h). Its shallow bucket design prevents adhesion and provides strong sealing, making it suitable for low-abrasive powders.

For granular organic fertilizers (such as extrusion granulation): we recommend the TH chain bucket elevator (lifting height 4.5-40m, conveying capacity 35-185m³/h). It features a deep bucket (SH type) with a high lifting capacity and wear resistance, making it suitable for loose particles.

For wet, sticky organic fertilizers (such as biogas sludge): we recommend the stainless steel bucket elevator (lifting height 4-30m, conveying capacity 15-60t/h). Its corrosion-resistant design and self-cleaning drum prevent adhesion and clogging.

High-temperature organic fertilizer (such as late-stage composting): TH or NE plate chain elevators are required (temperature resistance ≤ 250°C). The NE series has a lifting capacity of 15-800m³/h. The plate chain structure is wear-resistant and suitable for high-temperature bulk materials.

Why choose bucket elevator to transport organic fertilizer?

Organic fertilizer conveying bucket elevator can not only lift organic fertilizer vertically in organic fertilizer production, but also adopts a sealed structure, which can convey dust-free and reduce materials, with a conveying capacity of up to 500 tons per hour.

Efficient Vertical Conveying: A hopper continuously carries organic fertilizer, ideal for vertically lifting it from low to high locations, saving space and improving conveying efficiency.

Enclosed and Dust-Proof Conveying: Organic fertilizer easily generates dust and odor. Organic fertilizer conveying bucket elevators utilize a closed structure, with the entire conveying process handled within sealed pipes or tanks to prevent leaks and reduce environmental pollution.

Adaptability: The bucket elevator can handle a variety of organic fertilizer forms, including granular, powdered, lumpy, and moist. The hopper's anti-stick and anti-clogging design ensures stable operation.

Stable Operation and High Capacity: Bucket elevators offer a simple structure and stable operation, meeting the large-scale transportation needs of organic fertilizer production lines and other applications. They are also relatively easy to maintain.

What are the applications of Organic fertilizer conveying bucket elevator?

Organic fertilizer conveying bucket elevator can convey powdered, granular and small-block organic fertilizers. It is commonly used in the whole process of organic fertilizer production, processing and transportation, such as: raw material transportation and lifting, compost raw material warehousing/feeding, material transfer in production and processing, finished product storage and packaging, etc.

Organic fertilizer production: used to convey fermented organic fertilizer from the fermentation area to drying, screening or packaging equipment.

Composting plant: used to lift compost materials to compost turning machine or sorting equipment.

Agricultural cooperatives: used for storage and distribution of organic fertilizers.

Biomass energy plant: used to convey organic waste to fermentation tanks or processing equipment.

Horticulture and gardening: used for distribution and application of organic fertilizers.

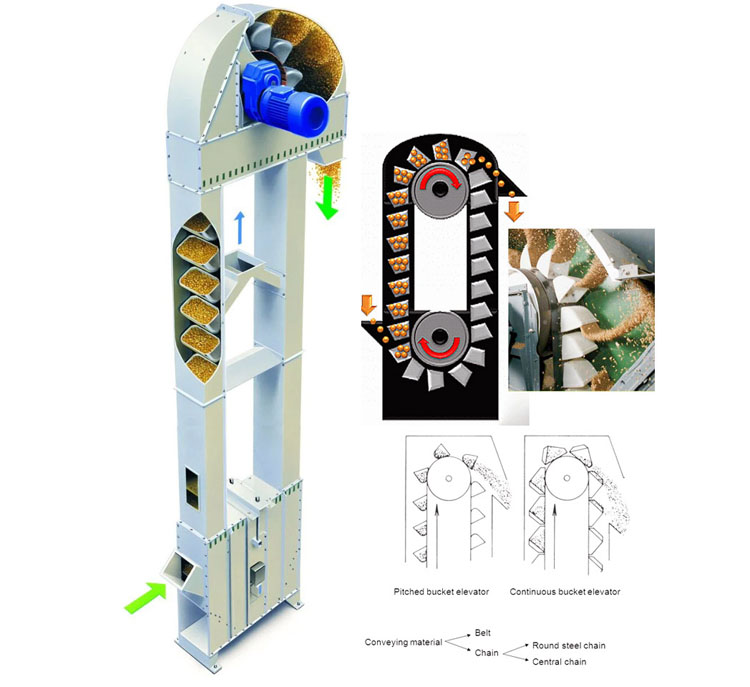

How does the organic fertilizer conveying bucket elevator work?

When the organic fertilizer conveying bucket elevator is working, organic fertilizer enters the bottom of the elevator through the feed port; after the bucket is loaded with materials at the bottom, it is lifted upward with the movement of the belt or chain; when the bucket reaches the top, the materials are discharged from the discharge port by centrifugal force or gravity; the empty bucket then returns to the bottom and the above process is repeated.

Organic fertilizer conveying bucket elevator parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

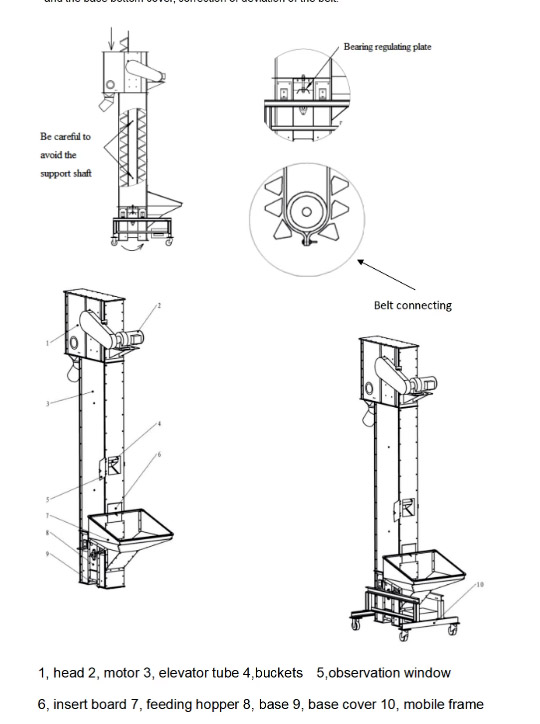

What are the structures of organic fertilizer conveying bucket elevator?

The structure of organic fertilizer conveying bucket elevator includes hopper, belt, driving device, casing, feed port, discharge port and tensioning device.

Hopper: a container for carrying organic fertilizer, usually made of wear-resistant and corrosion-resistant materials.

Belt or chain: connects and drives the hopper to ensure continuous operation.

Drive device: includes a motor and a reducer to provide power.

Shell: a closed structure to prevent dust from spilling and material from falling.

Feed port and discharge port: used for material input and output respectively.

Tensioning device: adjusts the tightness of the belt or chain to ensure stable operation.

Organic fertilizer conveying bucket elevator solution

| Customer case | Application scenario | Lifting amount | Lifting height |

| An organic fertilizer production plant in Egypt | Used to transport fermented organic fertilizer from the fermentation area to the drying equipment, significantly improving production efficiency and reducing labor costs. | 15 tons/hour | 12 meters |

| An Indonesian agricultural cooperative | Used for storage and distribution of organic fertilizers, the equipment has high durability and low maintenance costs, and has been highly praised by customers. | 30 tons/hour | 25 meters |

| A composting plant in Hebei | Used to lift composting materials to the compost turning machine, the equipment operates stably and has strong adaptability, meeting the high-efficiency requirements of composting treatment. | 8 tons/hour | 12 meters |

How to select organic fertilizer conveying bucket elevator?

Organic fertilizer characteristics: Consider factors such as material form, moisture content, corrosiveness, and viscosity. For powdered organic fertilizer, a shallow hopper design is recommended to prevent adhesion, while for granular organic fertilizer, a deep hopper structure is recommended to ensure adequate conveying capacity. For organic fertilizers with high moisture content, a non-clogging hopper and self-cleaning device are recommended. Since organic fertilizers are often corrosive, stainless steel or anti-corrosion treatments can effectively extend equipment life. For high-viscosity materials, easy-to-clean hoppers and conveyors are required, and unloading methods should be optimized to prevent residue.

Determine the transportation requirements: Determine the amount of organic fertilizer that needs to be transported per hour based on the production scale, with a maximum transport capacity of 800 tons/hour; the lifting height can be determined based on the site layout, with a maximum lifting height of 60 meters.

Choose the appropriate model: According to the characteristics and transportation requirements of organic fertilizer, powdered or small-particle organic fertilizer is suitable for centrifugal unloading, which has a fast conveying speed; block or viscous organic fertilizer is suitable for gravity unloading, which is more thorough and has less residue; the continuous type is suitable for scenarios with large conveying volume and high lifting height, and has stable operation; the intermittent type is suitable for small-scale production or scenarios that require precise control.