Multi-discharge bucket elevators

Friday November-07 2025 17:25:26

Multi-discharge bucket elevators are based on ordinary Z-type bucket elevators with the addition of 2-7 discharge ports, which can simultaneously supply materials to multiple workstations or silos, solving the problem of multiple material transfers at a single discharge point. They can lift powder, granules, and small block materials to a designated position through horizontal and vertical conveying and discharge from multiple discharge ports. The distance between each discharge point is about 2 meters, and the hourly lifting capacity is 5-100 cubic meters. Depending on the type of material being lifted, there are shallow buckets for powders and granules, deep buckets for block or sticky materials, and wear-resistant steel buckets for easily worn materials.

Multi-discharge bucket elevators video

What types of multi-discharge bucket elevators are available?

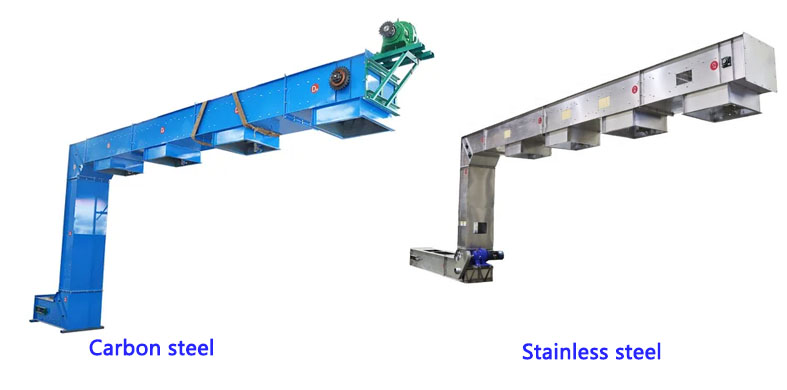

Multi-discharge bucket elevators use different materials depending on the type of material they transport. The main options are carbon steel and stainless steel. Carbon steel is cheaper and more wear-resistant, suitable for transporting non-corrosive, dry, lumpy, granular, or powdery materials such as ores, coal, cement, sand, and grains. 304 or 316 stainless steel, on the other hand, offers excellent corrosion resistance and hygiene, and is often used to transport corrosive, moisture-sensitive, or highly hygienic materials, such as chemical acids and alkalis, food ingredients, pharmaceutical intermediates, and brine media. The main difference between carbon steel and stainless steel lies in their corrosion resistance and hygiene standards. Carbon steel is less corrosion-resistant and has a lower hygiene rating, making it suitable for general industrial applications and more economical. Stainless steel is corrosion-resistant, moisture-proof, and easy to clean, often used in special conditions with high hygiene requirements or high temperatures, but it is more expensive. The choice depends on the characteristics of the material and the operating environment.

What are the advantages of multi-discharge bucket elevators?

Multi-discharge bucket elevators can be equipped with 2-7 unloading points as needed, making them suitable for the graded conveying and zoned storage of materials in complex production processes. They can replace multiple single unloading elevators, reducing investment in intermediate transfer equipment in the conveying process. Unloading control is precise, with each unloading point equipped with an independent control mechanism, allowing for individual start/stop or coordinated operation to prevent material mixing and misplacing, ensuring accurate unloading. Furthermore, the conveying process uses a fully enclosed structure, preventing dust and cross-contamination. Low-speed, gentle material conveying results in a very low breakage rate. The conveying operation is adjustable, and parameters such as bucket size, horizontal conveying length, lifting height, and unloading point spacing can all be customized to meet specific requirements.

How do multi-discharge bucket elevators work?

When a multi-discharge bucket elevator is working, material enters through the bottom inlet and is loaded into hoppers on a chain. The full hoppers are then conveyed vertically upwards along the inner wall of the machine to the top by the chain. When the material reaches the discharge point, the corresponding discharge valve automatically opens, and the hopper automatically flips and discharges from the corresponding discharge port. The empty hopper is then conveyed downwards along the chain to the bottom from the other end, and the loading and conveying process continues.

Multi-discharge bucket elevator parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

What are the applications of multi-discharge bucket elevators?

Multi-discharge bucket elevators are used to distribute a material to multiple workstations or silos. They are commonly used in scenarios requiring multi-point unloading and centralized material supply. They can be used in industries such as food, pharmaceuticals, chemicals, feed, building materials, mining, and metallurgy to transport materials such as cement raw meal powder, clinker, slag powder, fertilizer granules, coal powder, soda ash, wheat, corn, soybeans, peanuts, ore crushed materials, metallurgical slag, coke, talc powder, fly ash, quartz sand, urea granules, limestone, and coal lumps.

Multi-discharge bucket elevators customer case

| Application Scenarios | Material Lifting | Lifting Amount | Lifting Height |

| A large iron ore beneficiation plant in China provides multi-point feeding for 2 ball mills + 1 magnetic separator | Iron ore crushed material (particle size <40mm) | 80m³/h | 32m |

| A grain storage and logistics center in India unloads materials to multiple processing workshops and finished product warehouses. | Mixed grains of corn and wheat | 25m³/h | 18m³ |

| A medium-sized cement plant in Pakistan distributes clinker from its storage silo to multiple batching silos at multiple points. | Cement clinker and slag powder | 50m³/h | 28m³ |

| A plastic pellet production base in Vietnam precisely supplies materials to three extrusion production lines. | Polyethylene plastic pellets (particle size 2-5mm) | 35m³/h | 22m |

Multi-discharge bucket elevators manufacturer

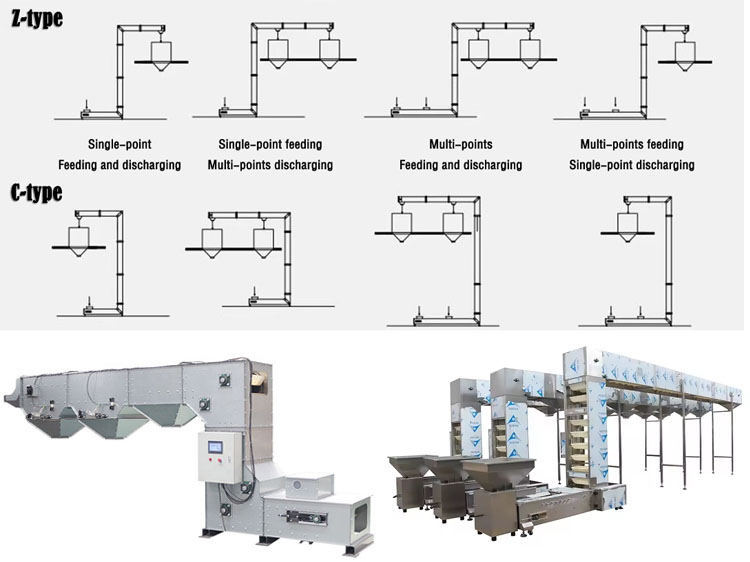

Dahan offers a variety of multi-discharge bucket elevators with Z-type, C-type, and ZC-type hybrid conveying methods to meet the needs of conveyed materials and application scenarios. Materials include carbon steel and stainless steel, and bucket types include deep buckets, shallow buckets, and pointed buckets, with capacities ranging from 1L to 6L. Structures include open and closed types. Lifting heights can reach 30 meters, and lifting capacities range from 5-100 cubic meters per hour. Factory direct sales, prices range from $500 to $9400. Furthermore, additional functions can be added according to material properties and scenario requirements, such as mobile, dust-collecting, explosion-proof, and variable frequency control systems.

Recommend Product

- Z Type Bucket Conveyor

- Bucket Elevator for Sugar

- Stainless Steel Bucket Elevator

- Z type conveyor for liquid-filled pouch