Montmorillonite clay powder bucket elevator

Saturday November-29 2025 15:32:01

A Montmorillonite clay powder bucket elevator is a type of elevator used for the vertical transport of montmorillonite clay powder. It uses buckets fixed to a chain to vertically lift the powder from a lower to a higher position. It can be used for the transfer and feeding of montmorillonite clay between stages of processing, including crushing, grinding, storage, and packaging. Because montmorillonite clay powder is very fine and lightweight, it easily generates dust during transport. Therefore, a closed conveyor structure is generally used to effectively prevent dust from escaping. The conveying height can reach 50 meters, and the hourly conveying capacity is 5-100 cubic meters.

Due to the fine texture and tendency of montmorillonite clay powder to clump, shallow buckets with a large inclination angle and shallow depth are generally chosen when using a Montmorillonite clay powder bucket elevator. This facilitates unloading and reduces the amount of montmorillonite clay powder remaining in the bucket. The elevator is typically made of stainless steel, which is wear-resistant and corrosion-resistant, allowing it to transport even slightly damp materials. Furthermore, the cleanliness and hygiene of stainless steel ensures the purity of the material.

What types of Montmorillonite clay powder bucket elevators are there?

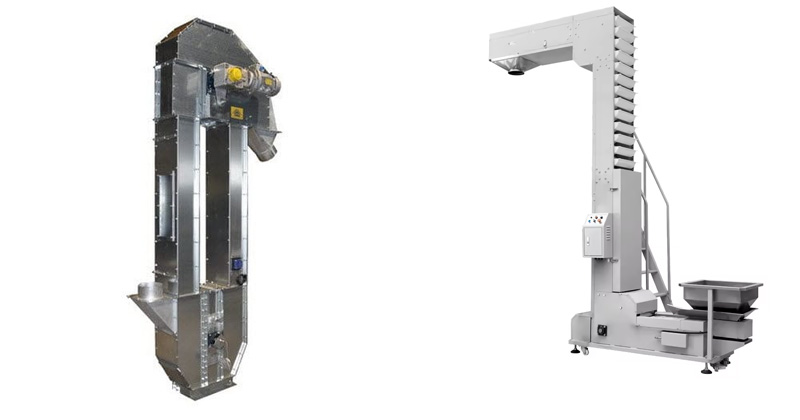

There are two main types of Montmorillonite clay powder bucket elevators: vertical and Z-shaped. They differ in the types of montmorillonite clay powder they can transport, as well as in their application scenarios and lifting heights.

Vertical Montmorillonite clay powder bucket elevators are primarily used for conveying montmorillonite clay powder at relatively high heights and with large throughputs. They use belts or chains to lift buckets from a lower position to a designated height of 10-50 meters, with a conveying capacity of up to 500 cubic meters. They are suitable for dry, slightly moist montmorillonite clay powder with a moisture content ≤15% and slightly agglomerated powder.

Z-type Montmorillonite clay powder bucket elevators are generally used in complex factory layouts requiring multi-station material supply. They can perform a combination of horizontal conveying, vertical lifting, and then horizontal conveying of montmorillonite clay powder on a production line. They allow for single-point or multi-point feeding and discharging, easily connecting multiple production lines or multiple silos at different heights. Their lifting height is 3-20 meters, and their lifting capacity is 5-50 cubic meters. They are suitable for conveying dry montmorillonite clay powder and mixtures containing granules.

What are the applications of Montmorillonite clay powder bucket elevators?

The Montmorillonite clay powder bucket elevator is primarily used in montmorillonite clay powder production lines to transport crushed coarse powder, ground fine powder, and for the storage and packaging of finished montmorillonite clay powder. It essentially connects the feeding and transfer processes between different stages of montmorillonite clay powder production, including crushing, grinding, grading, and packaging. It can be used to transport various types of montmorillonite materials, such as raw materials, dry clay, 80-200 mesh fine powder, and granular clay powder.

What are the advantages of a Montmorillonite clay powder bucket elevator?

Made of stainless steel with a fully enclosed shell, the Montmorillonite clay powder bucket elevator prevents dust leakage and environmental pollution when conveying fine, easily agglomerated materials like montmorillonite clay powder. Combined with a shallow hopper, it ensures thorough unloading without residue. With a lifting height of 5-30 meters and a large conveying capacity of 10-500 cubic meters per hour, it is suitable for various montmorillonite clay powder processing conditions. Depending on the application scenario, it offers vertical and horizontal + vertical combined conveying modes to flexibly meet different user needs. For dusty materials with explosion risks during conveying, an explosion-proof design is available to avoid flammable and explosive hazards. Customized hopper size, shape, motor power, and other configurations are also supported.

How does the Montmorillonite clay powder bucket elevator work?

When the Montmorillonite clay powder bucket elevator is working, it scoops montmorillonite clay powder from the bottom using a hopper. The full hopper is then vertically lifted along the inner wall until it discharges at the top outlet. The empty hopper returns to the bottom from the other side for reloading. The hopper used for conveying the montmorillonite clay powder is a shallow stainless steel hopper. The stainless steel material is non-stick, and the shallow hopper discharges without residue. The sealed casing prevents dust accumulation.

Montmorillonite clay powder bucket elevator parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

Montmorillonite clay powder bucket elevator customer cases

| Application Scenarios | Material Conveying | Lifting Height | Lifting Capacity |

| Chemical Industry: Drilling Mud Additive Production | 92% Purity Industrial Grade Sodium-Based Montmorillonite Clay Powder | 18m | 25m³/h |

| Building Materials Industry: Ceramic Raw Material Processing | Particle size 200 mesh calcium-based montmorillonite clay powder | 12m | 15m³/h |

| Preparation of water treatment adsorption materials for the environmental protection industry | High-purity montmorillonite clay powder | 22m | 30m³/h |

| Raw material processing for feed mycotoxin binders in the agricultural industry | Food-grade standard feed montmorillonite clay powder | 8m | 8m³/h |

Recommend Product

- Bentonite conveying bucket elevator

- Gangue bucket elevator

- Z Type Bucket Conveyor

- Aggregate Conveying Bucket Elevator