How does the vertical bucket elevator work?

Tuesday October-14 2025 16:15:48

vertical bucket elevator work process

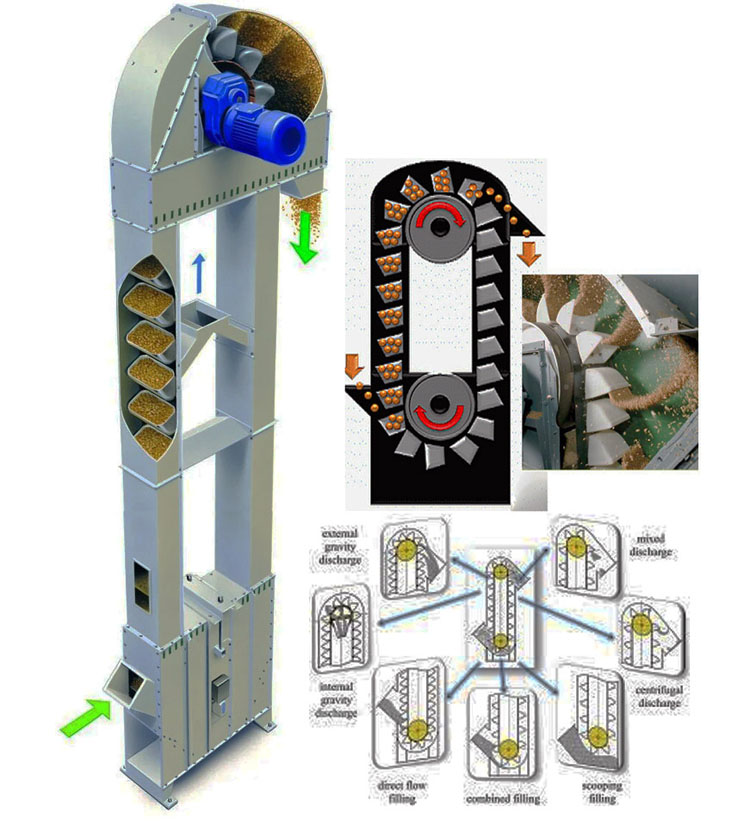

Loading: When the hopper, fixed to a traction mechanism (rubber belt or chain), reaches the bottom inlet, it automatically scoops material from the pile (generally used for small, highly fluid materials such as grain and flour). For large, heavy materials such as ore and coal, gravity feeds the hopper directly through the inlet. This inflow feeding method prevents impact and wear on the equipment caused by hard objects.

Lifting: The filled hopper is lifted smoothly upwards by a chain or belt. The entire lifting process occurs within a closed casing, preventing dust and ensuring safe operation. The lifting height can be designed to meet site requirements, up to 60 meters.

Discharging: When the hopper reaches the top, the material is ejected from the hopper by a combination of centrifugal force and gravity. The ejected material is discharged through the discharge chute, completing the entire lifting and conveying process. Discharging options include centrifugal discharge (for powdered materials, the hopper moves at high speed (1-2 m/s) at the top, causing the material to be ejected by centrifugal force) or gravity discharge (suitable for fragile, bulk materials, as the hopper flips and the material naturally slides down, minimizing breakage losses). After discharge, the empty hopper descends along the inside of the casing to continue loading.

What are the advantages of vertical bucket elevator when working?

When the vertical bucket elevator is working, its main feature is the space-saving vertical transportation. Compared with traditional horizontal conveying equipment, it can greatly reduce the ground occupation and is especially suitable for use in occasions with compact factory layout, easily solving the problem of material transfer between multi-layer production. It can operate continuously, and through the closed-loop operation of the bucket circulation, loading, lifting and unloading are seamlessly connected to achieve uniform feeding. It can further enhance the selection of hopper types for different types of materials, including deep buckets and shallow buckets, and can stably convey a variety of bulk materials such as granular ore, lumpy sand and gravel, powdered cement, etc., with an hourly conveying capacity of up to 800 cubic meters and a lifting height of up to 60 meters.

FAQs about vertical bucket elevators

What is the principle behind the installation of a vertical bucket elevator?

The installation process for a vertical bucket elevator follows the same principles as the original. The hopper is installed on a belt or chain to ensure smooth operation within the housing. During installation, the foundation must be firm and level, the housing must be vertical, and the axes of the drive and tensioning devices must be aligned. The hoppers must be evenly spaced and installed. This even distribution balances the load on the traction components and prevents local overload and breakage. Finally, the housing joints must be sealed to reduce dust leakage and environmental contamination, while also preventing material loss that affects conveying efficiency. The coordination of these steps forms the core logic of the installation.

Based on the principle, what is the maximum height a vertical bucket elevator can reach?

Based on the principle, vertical bucket elevators can reach heights ranging from 5 to 60 meters. Belt-driven elevators have a lifting height of 5 to 40 meters and are suitable for general material lifting. Plate chain elevators have a lifting height of 30 to 60 meters and are suitable for heavy material lifting. Chain elevators have a lifting height range of 10 to 50 meters.

What are the applications of vertical bucket elevators?

Vertical bucket elevator can be used for vertical lifting of various dry powders, granules, blocks and other bulk materials. It is commonly used for lifting materials such as ore, cement, grain, aggregate, fertilizer, coal, etc., but is not suitable for materials with high viscosity and water content such as sludge.

Vertical Bucket Elevator Manufacturers

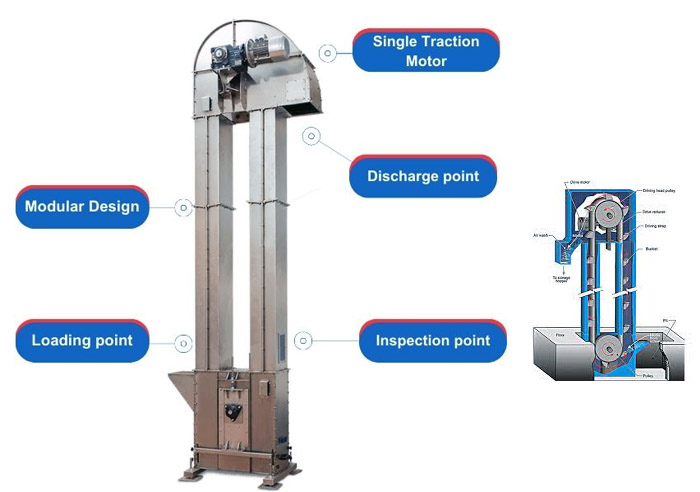

In short, a vertical bucket elevator works by using a bucket connected to a rotating belt or chain to lift materials vertically, providing an efficient and reliable solution for bulk material handling. Its equipment mainly includes a shell, a traction member (belt/chain: driving the bucket for continuous circulation), a hopper (for loading and unloading materials for transportation), a drive wheel (head wheel), a redirecting wheel (tail wheel), a tensioning device, a guide device, a feed port (where materials are fed into the elevator) and a discharge port (where materials are discharged). It is a device that realizes the transportation of materials between different levels.