Heavy duty chain bucket elevator

Friday December-12 2025 16:55:43

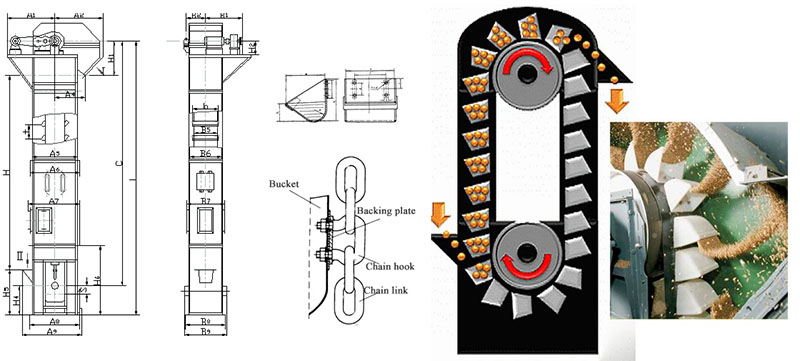

Heavy duty chain bucket elevators are used for vertically lifting various bulk materials, such as abrasive, rough-textured, or high-temperature powders, granules, and lumps, in harsh working conditions. Driven by a chain, the buckets vertically lift the bulk material from a low position to a designated height. They can also be used for lifting heavy materials such as cement, aggregates, and coal. Lifting heights range from 3 to 60 meters, with a lifting capacity of up to 500 cubic meters per hour. Power outputs range from 2.2 to 250 kW.

Heavy duty chain bucket elevators are equipped with manganese steel and stainless steel buckets of varying capacities from 1L to 8L. These buckets offer large capacity, wear resistance, and a gentle material transport method to prevent damage during transport. The fully enclosed structure minimizes material leakage. Single-chain and double-chain options are available to suit different heavy materials being lifted.

What types of Heavy duty chain bucket elevators are available?

Heavy duty chain bucket elevators, depending on the material being lifted and the lifting capacity, can be divided into single-chain and double-chain types. Generally, chain bucket elevators between NE15 and NE30 models use a single chain, while those between NE50 and NE800 models use a double chain.

Single-chain Heavy duty chain bucket elevator: These elevators use a single chain to pull the bucket. They have a simple structure and manufacturing costs 15%-20% lower than double-chain models. They are suitable for medium-sized, non-abrasive loose materials, with a lifting capacity of 5-50 m³, and are commonly used in small to medium production capacity applications.

Double-chain Heavy duty chain bucket elevator: Utilizing two synchronously driven chains arranged symmetrically, with each end of the bucket fixed to one chain, its load-bearing capacity is 1.8-2.5 times that of a single-chain model of the same specifications. The chains experience uniform stress and can withstand the impact load of large materials. Its service life is 30% longer than a single-chain model. A typical NE50 model chain bucket elevator has a lifting capacity of 80 cubic meters per hour, with a bucket size of approximately 650*1240mm, chain pitch of 152.4mm, bucket spacing of 304.8mm, and bucket width of 300mm. The bucket running speed is approximately 0.5m/s. It can be used for lifting highly abrasive, large-particle, heavy-duty materials, with a lifting capacity of 80-500m³.

What are the advantages of a Heavy duty chain bucket elevator?

A Heavy duty chain bucket elevator uses a high-strength steel plate chain to pull the buckets. It boasts strong load-bearing capacity and wear resistance, and can handle abrasive, high-temperature, heavy materials or continuously lift large quantities of materials. The lifting capacity can reach 500 cubic meters, and the lifting height can be customized to meet specific needs, up to 60 meters. It can connect to complex layouts such as high-level silos and multi-layer production lines without requiring additional transfer devices. The bucket shape and chain material can be adjusted according to the actual material characteristics, and the lifting speed can be adjusted according to production requirements.

How does a Heavy duty chain bucket elevator work?

When the Heavy duty chain bucket elevator is in operation, the motor drives the reducer to rotate the head sprocket, which in turn pulls the thickened bucket fixed to the chain. When both buckets descend with the chain to the bottom feed inlet, they scoop up the material. The deep bucket design and thickened bucket walls prevent heavy materials from falling or the bucket from deforming during lifting. Then, the chain drives the load-bearing buckets to be lifted vertically along the frame. Throughout the process, the load-bearing capacity of the stable guide rails and high-strength chain ensures that the heavy materials do not shift or get stuck during the lifting process. After reaching the top, the chain buckets rotate with the sprocket, and the material is smoothly unloaded to the discharge port through the combination of centrifugal force and gravity, completing the vertical conveying.

Heavy Duty Chain Bucket Elevator Parameters

| Model | Lifting Capacity (m/h) | Bucket Speed (m/s) | Spindle Speed (n/min) | Bucket | Chain Pitch (mm) | Running Part Weight (Kg/m) | Material Size (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume (L) | Bucket Width (mm) | Bucket Spacing (mm) | |||||||||||

| Percentage Allowed | |||||||||||||

| 10 | 25 | 50 | 75 | 100 | |||||||||

| NE15 | 15 | Approximately 0.5 | 16.54 | 2.5 | 250 | 203.2 | 101.6 | 27.5 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 30 | Approximately 0.5 | 16.54 | 7.8 | 300 | 304.8 | 152.4 | 35 | 90 | 75 | 58 | 47 | 40 |

| NE50 | 60 | Approximately 0.5 | 16.54 | 15.7 | 300 | 304.8 | 152.4 | 64 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | Approximately 0.5 | 14.13 | 35 | 400 | 400 | 200 | 89 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 170 | Approximately 0.5 | 14.13 | 52.2 | 600 | 400 | 200 | 112.5 | 130 | 105 | 80 | 65 | 55 |

| NE200 | 210 | Approximately 0.5 | 10.9 | 84.6 | 600 | 500 | 250 | 134 | 170 | 135 | 100 | 85 | 70 |

| NE300 | 320 | Approximately 0.5 | 10.9 | 127.5 | 700 | 500 | 250 | 188 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 380 | Approximately 0.5 | 8.3 | 182.5 | 700 | 600 | 300 | 205 | 205 | 165 | 125 | 105 | 90 |

| NE500 | 470 | Approximately 0.5 | 7.1 | 260.9 | 700 | 700 | 350 | 223 | 240 | 190 | 145 | 120 | 100 |

| NE600 | 600 | Approximately 0.5 | 7.1 | 330.2 | 800 | 700 | 350 | 350 | 240 | 190 | 145 | 120 | 100 |

| NE800 | 800 | Approximately 0.5 | 6.2 | 501.8 | 800 | 800 | 400 | 313 | 270 | 220 | 165 | 135 | 110 |

What are the applications of a heavy duty chain bucket elevator?

A heavy duty chain bucket elevator can be used in cement plants, foundries, sand and gravel plants, steel plants, and other heavy-duty operations to vertically lift high-temperature, abrasive, and poorly flowing powders, granules, and small lumps. It can move bulk materials from one location to another and can be used to lift various materials such as cement, aggregates, limestone, coal, fly ash, coal gangue, ore, grains, and seeds.

Heavy Duty Chain Bucket Elevator Customer Case

In a clinker conveying project at a large cement plant in China, a heavy duty chain bucket elevator was selected. This elevator vertically lifts cement clinker with abrasive properties, a material temperature ≤250℃, a lifting height of up to 40m, and a minimum hourly lifting capacity of 60m³. The selected model is the NE630 chain bucket elevator. The SH-type deep buckets ensure no spillage of dry, loose materials. The traction chain is a high-strength plate chain for enhanced wear resistance. A 22kW motor provides stable power, ensuring reliable operation with a mean time between failures (MTBF) exceeding 30,000 hours. It is suitable for the harsh working conditions of the building materials industry, significantly reducing maintenance costs.

Recommend Product

- Chain Bucket Elevator

- TH Chain Bucket Elevator

- NE Plate Chain Bucket Elevator

- Heavy duty bucket elevator