Heat-resistant bucket elevator for cement clinker

Thursday November-06 2025 14:35:28

Heat-resistant bucket elevator for cement clinker is a vertical conveying equipment designed for high-temperature materials (such as cement clinker, limestone, gypsum, etc.) on cement production lines. It is mainly used to transport high-temperature 1000°C cement clinker from one location to another. It has good sealing performance and can effectively prevent dust leakage and flying. It is widely used in cement manufacturing, metallurgy, chemical industry and other industries.

Compared with ordinary bucket elevators, heat-resistant models use high-strength alloy chains, high-temperature resistant bearings, and special sealing structures to ensure that the equipment can work stably for a long time in high temperature and high wear environments, avoiding problems such as chain jamming and chain breakage caused by thermal expansion.

Why choose Heat-resistant bucket elevator to transport cement clinker?

Cement clinker has the characteristics of high temperature (200-1000°C), high abrasiveness, and easy dust. Ordinary conveying equipment is difficult to meet the needs, and Heat-resistant bucket elevator has the following advantages:

High temperature resistance: using heat-resistant steel and special lubrication system, it can adapt to 1000°C high temperature environment.

Sealed and dustproof: fully enclosed structure, reducing dust spillage, meeting environmental protection requirements.

Large conveying capacity: The conveying capacity of a single machine can reach 800m³/h, meeting the needs of large cement plants

High efficiency and energy saving: inflow feeding + gravity unloading, reducing return material, saving 30% energy compared with traditional equipment.

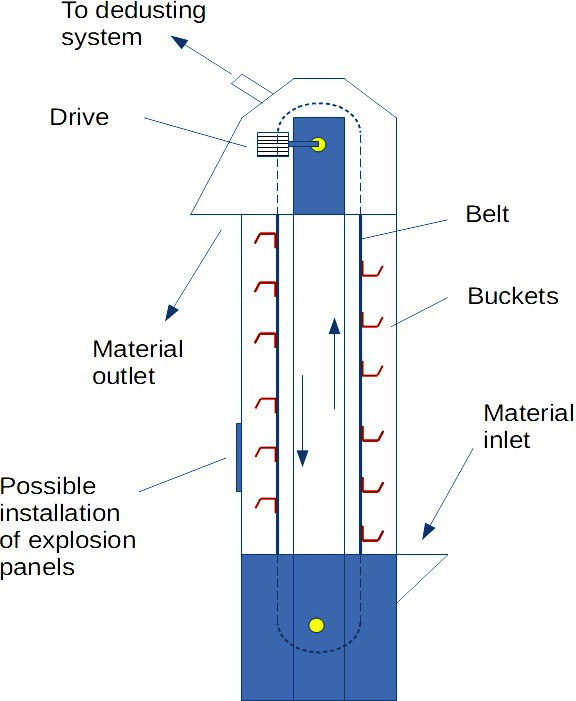

How does the heat-resistant bucket elevator for cement clinker work?

The reducer is driven by the motor, so that the chain drives the lifting bucket to move up and down in a cycle. The material is loaded into the lifting bucket from the bottom, gradually lifted to the upper part with the movement of the chain, and unloaded to the target position at the top. The whole process is completed by the cooperation of the motor and the chain.

What are the structures of Heat-resistant bucket elevator for cement clinker?

Lifting frame: The frame that supports the entire equipment.

Drive device: Provides power, usually a motor-driven reducer.

Lifting bucket: Used to load and lift materials.

Guide device: Ensure that the lifting bucket moves along the correct path.

Tensioning device: Maintain the tension of the chain.

Components such as reducers, gears, chains and motors work together to lift materials.

What are the applications of Heat-resistant bucket elevator for cement clinker?

Heat-resistant bucket elevator for cement clinker is widely used in cement industry (clinker is transported to storage or mill after cooling), metallurgical industry (vertical lifting of high-temperature slag and sintering materials), chemical industry (continuous transportation of high-temperature resistant granular materials), etc.

Heat-resistant bucket elevator for cement clinkerCustomer case

| Application scenario | Solution | Customer feedback |

| A large cement plant in Vietnam: transporting cement clinker at a temperature of 200°C, with an output of 300 tons/hour. | Using NE200 heat-resistant bucket elevator, it has been running for 3 years without major repairs. | Energy consumption reduced by 25%, dust emission reduced by 90% |

| Saudi Arabia Coking Plant: High temperature coke pellet lifting, ambient temperature reaches 450°C. | Customized TH315 heat-resistant bucket elevator, equipped with heat-resistant bearings. | 2 years of continuous operation, chain wear rate is lower than the industry standard |

The heat-resistant bucket elevator for cement clinker is a key component in cement plants, which can efficiently and safely transport high temperature materials such as cement clinker vertically. Its rugged design, heat-resistant characteristics and reliability make it an important asset for optimizing material handling operations in industrial environments.