Grain Bucket Elevator

It can lift powder, granular grain or similar bulk materials vertically from a low location to a specified position, and the price range is $400 - $5,800.

| Lifting height | 50 meters |

| Conveying capacity | 5-100m³/h |

| Hopper capacity | 0.5-9L |

| Hopper spacing | 280-625mm |

| Operation speed | 1.4-2.2m/s |

What is Grain Bucket Elevator?

Grain Bucket Elevator is an elevator that scoops grains through a hopper for vertical transportation. It can lift grains vertically from a low place to another high place. The lifting height can reach 50 meters, the lifting volume can reach 100 cubic meters per hour, and the lifting speed can reach 2 meters per second. It can lift powder (flour, starch, sugar, etc.), granular (rice, wheat, corn, soybean, etc.) grains and similar materials. It is commonly used in the storage and processing of grain or cereals in industries such as flour mills, fertilizer plants, ethanol plants, malt plants and feed processing plants. Due to different lifting heights, different product types are selected, including stainless steel, carbon steel, continuous, etc. The hopper can be selected as shallow or deep according to the lifting material. We can also customize it according to your needs.

Grain Bucket Elevator Video

What types of Grain Bucket Elevators are there?

Grain Bucket Elevator has different models to choose from, depending on the type of grain being transported. There are four main types to choose from: centrifugal unloading, continuous, stainless steel, and heavy chain:

Centrifugal Grain Bucket Elevator: This elevator utilizes centrifugal force to discharge materials. Its high speed, reaching 1-3 meters per second, makes it suitable for free-flowing powders and granules, such as wheat flour and corn flour. It is not suitable for fragile, abrasive, or sticky materials.

Continuous Grain Bucket Elevator: Its tightly connected hoppers gently handle material, minimizing spillage and spillage. It also continuously elevates grain and is suitable for fragile or abrasive powders and granules.

Stainless Steel Grain Bucket Elevator: Constructed of 304 or 316L stainless steel, it is clean and hygienic, making it suitable for the food industry, which has strict requirements for grain processing hygiene.

Heavy-Duty Chain Grain Bucket Elevator: Utilizing a heavy-duty chain drive, it offers stable operation and is suitable for high-capacity grain lifting, long distances exceeding 30 meters, and high-load operations.

Why use bucket elevators for conveying grain?

Compared with traditional equipment such as screw conveyors and belt conveyors, the Grain Bucket Elevator has a higher conveying height of up to 60 meters when it comes to lifting grain. It is suitable for multi-story buildings or high-rise warehouses. It has a large lifting capacity of up to 100 cubic meters. In addition, the use of hopper conveying can reduce grain loss and maintain grain quality. The vertical structure design occupies a smaller area, saves ground space, has strong adaptability, reduces energy consumption, and saves costs.

Grain bucket elevator parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

All sizes can be designed, adjusted and manufactured to suit vertical packaging and meet the warehousing needs of grain businesses.

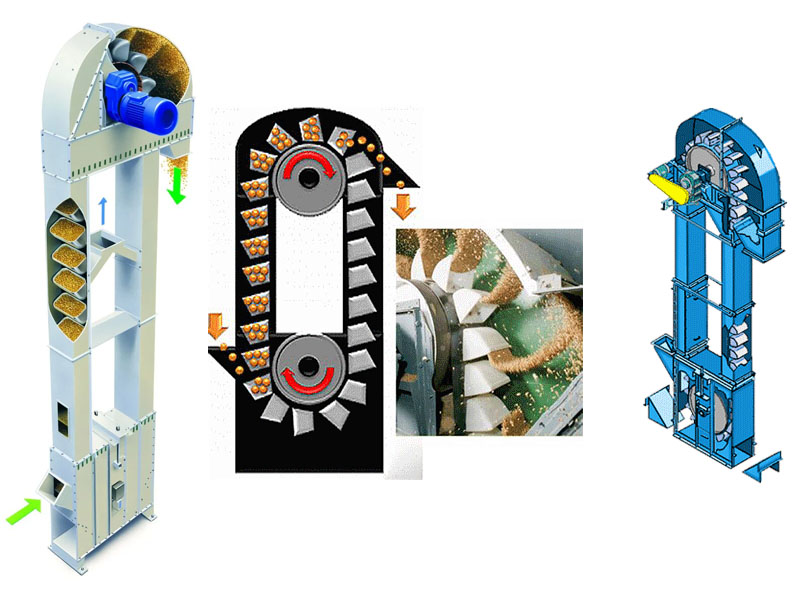

How does the grain bucket elevator work?

When the Grain Bucket Elevator is working, grain enters the elevator from the feed port and is dug by the hopper. The driving device then lifts the hopper filled with grain from the lower feed port to the upper discharge port for unloading. The empty hopper returns to the bottom for the next digging and conveying operation.

What is the purpose of a grain bucket elevator?

Grain Bucket Elevator is used in agricultural production, grain processing, storage, feed production and other industries to vertically transport powder, granules, small pieces of grain and bulk materials similar to grain from the ground to granaries, drying equipment, processing equipment, etc. It can be used to lift wheat, corn, rice, soybeans, soybean meal, flour, sorghum, rice, sesame, flax seeds, feed pellets and other materials.

Grain Bucket Elevator Customer Case

| Customer name | Application scenario | Conveying material | Conveying capacity (m/h) | Lifting height (m) |

| A grain processing plant | Wheat cleaning workshop | Wheat | 30 | 25 |

| A feed production enterprise | Feed raw material transportation | Corn | 45 | 30 |

| A grain warehouse | Grain storage and transportation | Rice | 50 | 35 |

| A certain subsidiary | Seed processing workshop | Various seeds | 20 | 20 |

| A food processing plant | Food raw material transportation | Flour | 25 | 15 |

Grain Bucket Elevator Manufacturer

Dahan Grain Bucket Elevator Manufacturer is a source manufacturer with 15 years of R&D and production experience. The bucket elevators we produce are made of carbon steel and stainless steel; the height is optional from 1 meter to 50 meters, and the models include TD series, TH series, TB series, NE series, as well as Z type and C type. They can also be customized according to your needs, such as: multi-point feeding or multi-point unloading, explosion-proof type, mobile type, speed regulation type, etc.

Sugar Bucket Elevator

Sugar Bucket Elevator Food Grade Bucket Elevator

Food Grade Bucket Elevator