Food Grade Bucket Elevator

It can be used to gently lift various types of food materials (powders, granules, and lumps) from low to high levels. The price range is $400-$6000.

Hopper Material: Food-grade plastic PP or 304/316L stainless steel

Conveying Capacity: 5-100 m³/h

Conveying Height: 2-40 meters

Conveying Speed: 2-5 m³/h

Bucket: 1.8L, 4.0L, and 6.0L (customizable)

Infeed Length: 863 mm

Discharge length: 1930 mm

What is a Food Grade Bucket Elevator?

The Food Grade Bucket Elevator is made of food-grade stainless steel or food-grade plastic and can be used to vertically convey food raw materials or finished products such as flour, grains, and candies. The food-grade material is corrosion-resistant, easy to clean, and has no sanitary dead corners. It can prevent the residual materials from breeding bacteria and avoid the contamination of materials during the conveying process. It meets food hygiene and safety standards. Depending on the properties of the different materials being lifted, you can choose a deep bucket (for conveying dry granular materials) or a shallow bucket (for easily agglomerated materials). Both can lift or unload safely and gently. The lifting height is 2-40 meters, and the maximum lifting volume can reach 100 cubic meters per hour. The elevator offers a lifting height range of 2-40 meters and a maximum lifting capacity of 100 cubic meters per hour.

The Food Grade Bucket Elevator can vertically lift powdered, granular, and small-block foods (such as grains, candy, nuts, and flour). Primarily used in the food industry, its design prioritizes hygienic, safe, and gentle handling, making it ideal for lifting fragile materials.

What applications does the Food Grade Bucket Elevator have in the food industry?

Because it complies with food hygiene standards, the Food Grade Bucket Elevator is commonly used in the production, processing, and transfer of food materials within the food industry. It can meet the vertical conveying needs of various food ingredients and finished products:

In grain and cereal processing: The Food Grade Bucket Elevator is used to transport raw grains such as corn, wheat, rice, and oats, or ground powders such as flour and rice flour, from the ground or low to high levels, such as from storage to processing steps like cleaning, grinding, and milling, preventing impurities and contamination throughout the entire process.

In snack food production: In the production of potato chips, biscuits, and candies, the Food Grade Bucket Elevator can transport semi-finished and finished products such as potato chips, biscuit dough, and candy granules. For example, it can lift candy granules from a mixing tank to a forming machine, ensuring a clean and sanitary conveying process that meets food safety requirements.

In fruit and vegetable processing, the Food Grade Bucket Elevator can be used for vertical transfer of washed fruit and vegetable chunks (such as carrots and apples) and dried fruits and vegetables from the washing tank to slicers and drying equipment. Its corrosion-resistant and easy-to-clean material prevents residual juice from breeding bacteria.

In dairy and baking, the Food Grade Bucket Elevator can transport ingredients such as milk powder, powdered sugar, flour, and butter granules. For example, it can lift milk powder from a storage tank to a mixing tank, preventing moisture and agglomeration. Furthermore, the food-grade material resists chemical reactions with the ingredients, ensuring product quality.

What are the advantages of the Food Grade Bucket Elevator?

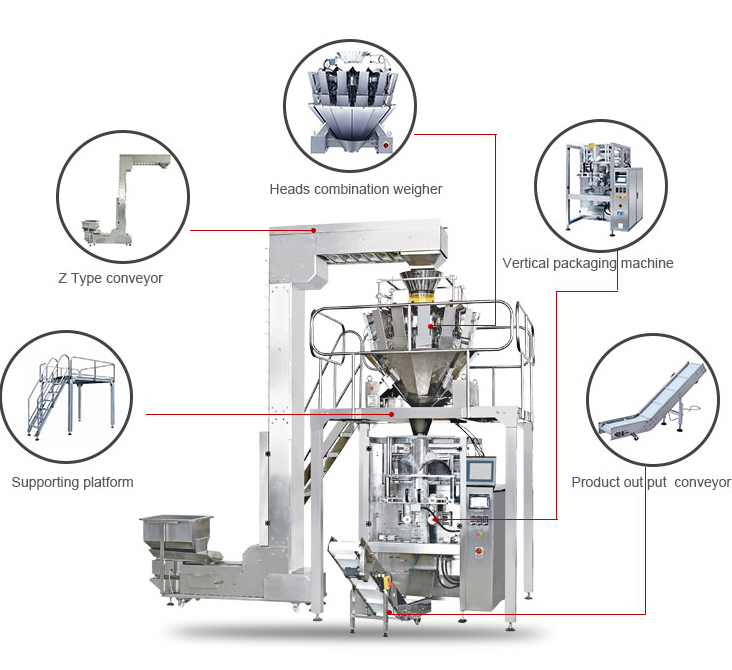

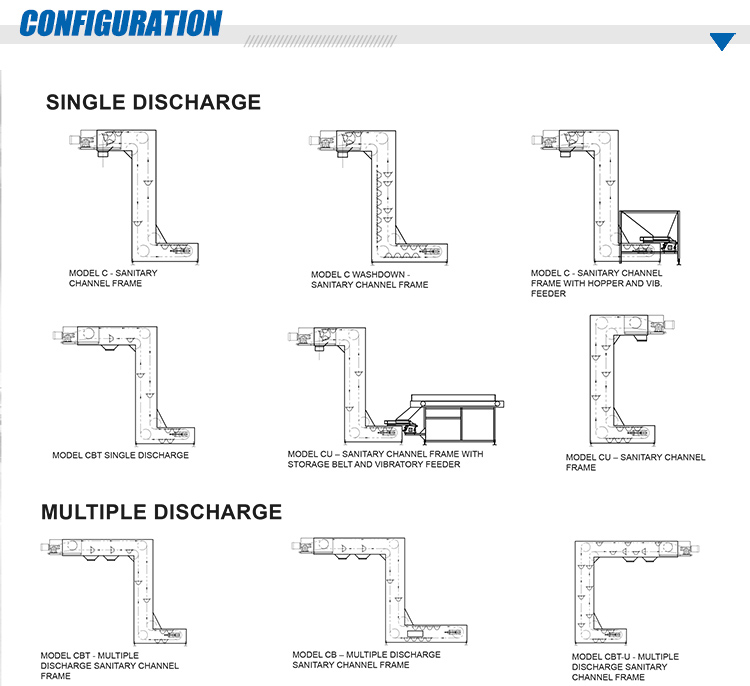

The Food Grade Bucket Elevator's body is constructed of 304 or 316L stainless steel, and its hopper is made of food-grade stainless steel or plastic. It is odorless, corrosion-resistant, and has no blind spots, preventing material residue and contamination during transportation, complying with food production hygiene standards. It can be customized to accommodate the properties of the material being lifted and the application, such as multiple feeding and unloading points. Movable wheels can be added to the bottom to accommodate different conveying scenarios, and an explosion-proof design is available for flammable and explosive powders. The hopper efficiently and gently handles a variety of food materials, from powders and granules to small chunks, while minimizing material breakage while ensuring conveying efficiency and lifting height. The hopper has a large capacity, available in 1.8L, 4.0L, and 6.0L sizes, and can be customized to meet your needs. It can also be used with packaging machines, weighing machines, sealing machines, and other equipment to ensure fully automated food material transfer and reduce contamination.

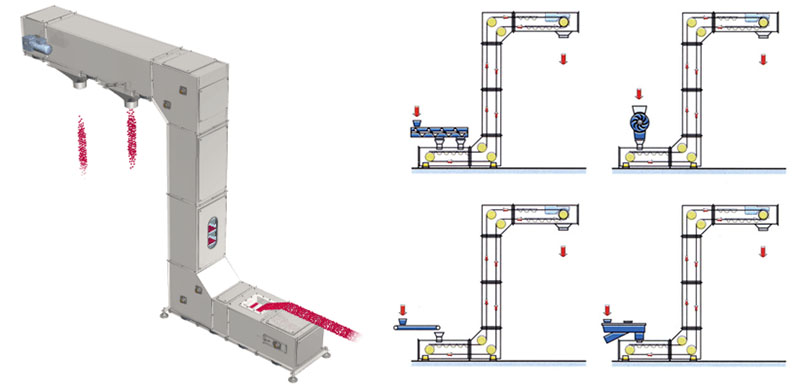

How does the Food Grade Bucket Elevator work?

When the Food Grade Bucket Elevator is working, the motor drives the hopper on the chain to descend to the bottom feed port, scooping food materials from the silo or feeding device; the hopper filled with materials is lifted upward along with the chain, and turns over with the rotation of the wheel body at the top driving wheel to pour the internal materials into the top discharge port, completing vertical transportation; the empty hopper continues to descend and enters the next cycle of lifting, realizing continuous and stable transportation of food materials.

Food Grade Bucket Elevator Specifications

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

What are the components of a Food Grade Bucket Elevator?

A Food Grade Bucket Elevator primarily consists of a drive unit (a food-grade motor, reducer, and drive sprocket/roller, providing power), a conveying mechanism (a food-grade stainless steel conveyor belt or chain, and a stainless steel/food-grade plastic hopper mounted on it, responsible for receiving and transferring materials), a feeder (usually an inclined or chute structure, guiding materials smoothly into the hopper), a discharger (a bell-shaped or curved design, ensuring complete discharge of materials from the tilting hopper), a tensioner (typically located at the bottom, adjusting the tension of the conveyor belt/chain to ensure stable operation), and a housing (made of food-grade stainless steel, with a closed structure to prevent dust leakage and foreign matter intrusion, and no dead corners, making it easy to clean).

Food Grade Bucket Elevator Optional Configurations

All food grade bucket elevators are equipped with an automatic chain tensioner and a built-in overload protection device. They are available in 304 or 316L stainless steel or food-grade plastic, with other materials available upon request. The hopper can be made of PP, ABS, 304 stainless steel, or other materials as needed. Hopper capacities include 1.8L, 2.4L, 3.6L, 6L, and 10L, with larger capacities available upon request.

Food Grade Bucket Elevator Customer Case

| Application Scenario | Material Lifting | Lifting Amount | Lifting Height |

| A Flour Mill in Pakistan | Flour | 15-25 cubic meters per hour | 30 meters |

| A Snack Food Factory in the United States | Semi-finished potato chips | 8-12 cubic meters per hour | 15 meters |

| A grain storage and transfer station in India | Rice | 35-65 cubic meters per hour | 20 meters |

| A pet food factory in China | Pet food pellets | 10-16 cubic meters per hour | 25 meters |

| A candy production plant in Vietnam | Candy | 5-10 cubic meters per hour | 18 meters |

Stainless Steel Bucket Elevator

Stainless Steel Bucket Elevator Sugar Bucket Elevator

Sugar Bucket Elevator