Fly ash bucket elevator

Sunday October-12 2025 16:34:45

Fly ash bucket elevator is a highly efficient continuous conveying equipment designed for vertical conveying of fly ash in coal-fired power plants, building materials factories and other industries. As the core product of [your company name], our elevator adopts a sealed structure and wear-resistant materials, which perfectly solves the problems of dust and wear during the conveying of fly ash.

Compared with traditional conveying equipment, Fly ash bucket elevator has significant advantages such as small footprint, high conveying efficiency and low energy consumption. It can easily lift fly ash from the ground to a storage silo or processing equipment 3 meters or even 120 meters high.

| Characteristics | Advantages | Significance for fly ash transportation |

| Sealing design | Fully enclosed casing structure | Prevent fly ash dust and meet environmental protection requirements |

| Wear-resistant configuration | Special steel plate/rubber hopper | Extend equipment service life and reduce maintenance costs |

| Efficient transportation | Lifting volume 15-800m³/h | Meet the transportation needs of power plants of different sizes |

| Energy-saving operation | Inflow feeding, gravity unloading | Reduce energy consumption and reduce operating costs |

| Highly flexible | Lifting height can reach 80 meters | Adapt to various plant height requirements |

Why choose bucket elevator to transport fly ash?

Fly ash, as a by-product of coal-fired power plants, has the characteristics of small fineness, easy dust, and certain abrasiveness, which puts forward special requirements for transportation equipment. After years of practical verification, bucket elevator has become the best solution for vertical transportation of fly ash. The main reasons include:

Excellent sealing and dustproof performance: The fully enclosed structure design effectively prevents fly ash from leaking during transportation, avoids environmental pollution, and meets increasingly stringent environmental protection requirements.

High vertical space utilization: Compared with chute or screw conveyors, bucket elevators can be arranged vertically, greatly saving plant space, and are particularly suitable for renovation projects with limited space.

Adapt to the characteristics of fly ash: In view of the fine particle characteristics of fly ash, we provide a variety of hopper options (shallow bucket, deep bucket, arc bottom bucket, etc.) to ensure efficient loading and complete unloading to avoid residue.

Wear-resistant design to extend life: Although fly ash is not as abrasive as ore, long-term transportation will still cause wear on the equipment. Our elevators are specially treated with wear-resistant steel plates or rubber linings, and the life of key components is increased by more than 30%.

Energy consumption advantage is obvious: the principle of inflow feeding and gravity unloading is adopted, which can save 40-60% energy compared with the pneumatic conveying system, greatly reducing the operating cost.

Easy maintenance: the modular design makes daily maintenance more convenient, and the combined sprocket used in the NE series can only replace the wheel rim after wear, reducing maintenance costs

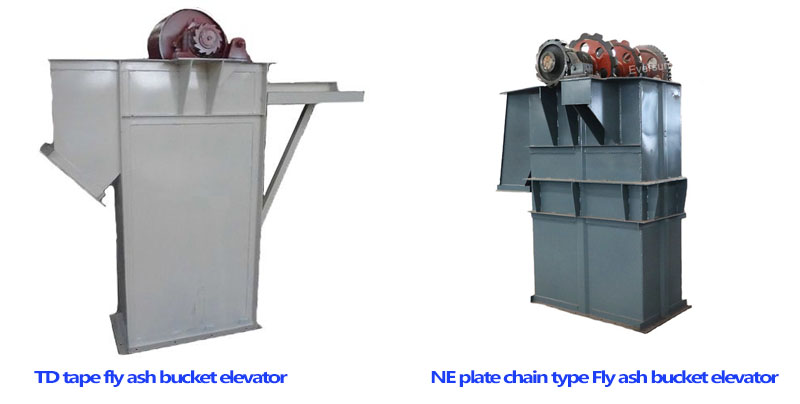

What are the types of Fly ash bucket elevators?

According to the traction mode and structural characteristics, Dahan provides two types of Fly ash bucket elevators. Users can choose the most suitable model according to material characteristics, conveying capacity and working environment.

| Comparison items | TD tape type Fly ash bucket elevator | NE plate chain type Fly ash bucket elevator |

| Traction components | Rubber belt | Alloy steel plate chain |

| Heat resistance | ≤60℃ | ≤250℃ |

| Maximum lifting height | 40m(ordinary)/80m(wire rope core) | 70m |

| Transportation range | 15-600m³/h | 15-800m³/h |

| Wear resistance | Good | Excellent |

| Initial investment | Low | High |

| Maintenance cost | Low | Medium |

| Typical application | Normal temperature fly ash conveying | High temperature/large volume fly ash conveying |

Fly ash bucket elevator parameters

TD type belt type fly ash bucket elevator parameters

| Model | Bucket width (mm) | Bucket capacity (L) | Conveying volume (m/h) | Lifting height (m) | Motor power (kW) |

| TD160 | 160 | 1.2 | 8-21 | ≤40 | 1.5-5.5 |

| TD250 | 250 | 3.2 | 22-42 | ≤40 | 3-7.5 |

| TD315 | 315 | 6.5 | 36-72 | ≤40 | 5.5-15 |

| TD400 | 400 | 12.6 | 66-125 | ≤40 | 7.5-22 |

| TD500 | 500 | 22 | 115-200 | ≤40 | 15-30 |

| TD630 | 630 | 42 | 190-340 | ≤40 | 18.5-45 |

NE type plate chain fly ash bucket elevator parameters

| Model | Conveying capacity (m³/h) | Material size (mm) | Lifting height (m) | Motor power (kW) |

| NE15 | 15 | ≤25 | ≤70 | 3-7.5 |

| NE30 | 32 | ≤40 | ≤70 | 5.5-11 |

| NE50 | 60 | ≤40 | ≤70 | 7.5-18.5 |

| NE100 | 110 | ≤55 | ≤70 | 15-30 |

| NE150 | 170 | ≤55 | ≤70 | 18.5-45 |

| NE200 | 210 | ≤70 | ≤70 | 22-55 |

| NE300 | 320 | ≤70 | ≤70 | 30-75 |

| NE400 | 360 | ≤90 | ≤70 | 37-90 |

| NE500 | 470 | ≤100 | ≤70 | 45-110 |

| NE600 | 600 | ≤100 | ≤70 | 55-132 |

| NE800 | 800 | ≤110 | ≤70 | 75-160 |

Note:

The conveying volume in the table is a reference value for fly ash (bulk density of about 0.6-1.0t/m³). The actual value may vary slightly due to material properties

The lifting height can be customized according to customer needs. Special design is required for more than 30 meters

The motor power depends on the lifting height and conveying volume, which needs to be calculated and determined according to actual conditions

Special models such as explosion-proof, high temperature resistant, and corrosion-resistant can be provided

How does the fly ash bucket elevator work?

The working principle of fly ash bucket elevator is to drive the body to rotate through the drive device, so that the conveying bucket moves upward along the track of the body. The material is loaded into the conveying bucket, and as the conveying bucket rises, the material is lifted to the top and then discharged through the discharge port. Throughout the process, the guide device and anti-deviation device ensure the stable operation of the conveying bucket to prevent deviation.

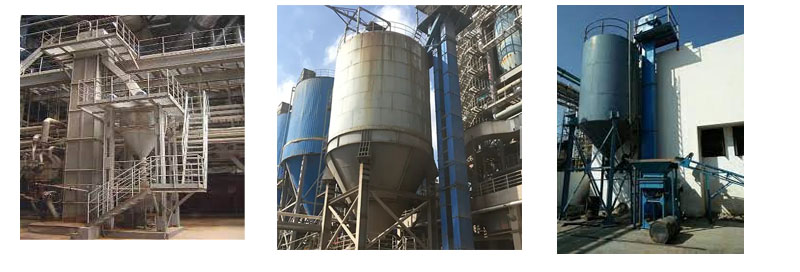

What are the applications of fly ash bucket elevator?

Dahan fly ash bucket elevator has been successfully applied in many industries such as power, building materials, metallurgy, and chemical industry.

Power industry (fly ash treatment in coal-fired power plants): vertical transportation from boiler dust collector ash hopper to ash storage bin, lifting of fly ash from the ground to the loading system, mixed transportation system of desulfurized gypsum and fly ash.

Building materials industry (comprehensive utilization of fly ash): raw material lifting of fly ash brick/block production line, admixture conveying system of cement plant, fly ash supply in aerated concrete production line.

Metallurgical and chemical industry: slag micro powder production line, red mud treatment system of alumina plant, powder raw material transportation of chemical plant

Other applications: feed lifting of fly ash sorting system, loading and unloading system of fly ash storage and logistics center, research and development test line of fly ash-based new building materials

Fly ash bucket elevator customer case

| Application scenario | Lift height | Lifting capacity | Equipment model | Customer feedback |

| Active lime production line in Inner Mongolia: lifting fly ash and limestone mixture | 38 meters | 600t/d | NE315 plate chain bucket elevator (3 units) | No major repairs in operation for three years, slight chain wear, fully meeting the needs of high-temperature material transportation |

| A large coal-fired power plant in Pakistan: transportation from electrostatic precipitator ash hopper to ash storage bin | 28 meters | 20 tons/hour, explosion-proof, equipped with intelligent monitoring system | TD500 belt bucket elevator (6 units) | Dust leakage <30mg/m³, far exceeding environmental protection standards |

| A fly ash brick production enterprise in Henan: improving wet fly ash with a moisture content of 8-12% | 45 meters | 170m³/h | 0.1-5mm | Solved the industry problem of wet ash sticking to the bucket, and increased production efficiency by 25% |

Fly ash bucket elevator plays a vital role in the efficient and safe handling of fly ash in industrial applications. Bucket elevators have the advantages of customizable design, continuous operation, efficient material handling and space saving, and are an indispensable and valuable asset in industries that require vertical transportation of fly ash.

Recommend Product

- Quartz sand bucket elevator

- NE Plate Chain Bucket Elevator

- Cement clinker conveying bucket elevator

- Bucket Elevator for Fly Ash