Fertilizer Conveying Bucket Elevator

Designed for vertical transportation of powdered or granular fertilizers, it can lift fertilizers vertically from one place to another designated height.

Price: $350-$6,900

Conveying capacity: 15-500 m³/h

Lifting height: 75 meters

Operating speed: 0.5 -1.5 m/s

Bucket capacity: 2.5-23.6 L, bucket distance: 203.2-882 mm

What is Fertilizer Conveying Bucket Elevator?

The Fertilizer Conveying Bucket Elevator is a bucket elevator designed for conveying granular, powdered, or lumpy fertilizers vertically or at an angle. It lifts fertilizer from a low level to a high level through a hopper, with a lifting height of 3-60 meters and a capacity of 5-400 tons of fertilizer per hour. It is commonly used in fertilizer production processes such as raw material feeding, post-mixing lifting, finished product packaging, and storage and stacking, improving fertilizer handling efficiency and reducing labor costs.

The Fertilizer Conveying Bucket Elevator's main body is made of wear-resistant and corrosion-resistant carbon steel or stainless steel (such as 304/316). The hoppers are available in deep, shallow, or pointed bottom configurations, depending on the characteristics of the fertilizer being lifted (e.g., compound fertilizer, organic fertilizer, urea, ammonium phosphate, and potash fertilizer). For example, a deep hopper is suitable for conveying fluid granular fertilizers, while a shallow hopper is suitable for conveying wet, sticky powdered fertilizers.

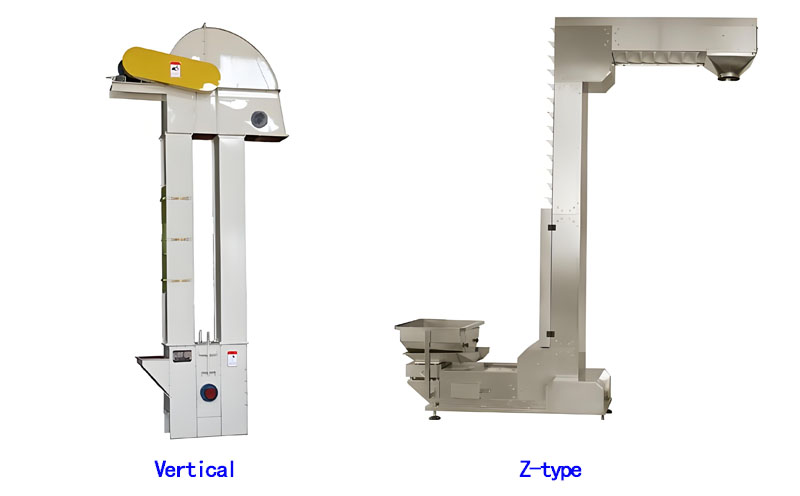

What types of fertilizer conveying bucket elevators are available?

In fertilizer production and processing, fertilizer bucket elevators are available in two types: vertical and Z-type. We can select the appropriate model based on the properties of the fertilizer being lifted and the application scenario. You can also contact us for a customized solution.

Vertical Fertilizer Conveying Bucket Elevators: Using a chain or belt drive, they can achieve vertical lift heights of 5-60 meters and a lifting capacity of 5-400 tons/hour. They are suitable for granular fertilizers (compound fertilizers, urea), powdered fertilizers (potassium dihydrogen phosphate), and organic fertilizers.

Z-Type Fertilizer Conveying Bucket Elevators: Using a multi-stage conveyor system with horizontal-vertical-horizontal steering, they can achieve lift heights of 3-30 meters and a lifting capacity of 3-100 tons/hour. They are suitable for conveying fertilizers that easily clump or have poor flowability, such as wet organic fertilizers and expanded fertilizers.

What are the applications of the Fertilizer Conveying Bucket Elevator?

The Fertilizer Conveying Bucket Elevator is primarily used for vertical conveying of various fertilizers throughout the entire fertilizer production, processing, and packaging process. Its applications include:

Raw Material Feeding and Pretreatment: The Fertilizer Conveying Bucket Elevator is used to lift raw materials (such as granular fertilizers, compound fertilizers, and organic-inorganic compound fertilizers) from the ground or low-lying areas to elevated silos or pretreatment equipment (such as mixers and crushers) for subsequent batching and mixing.

Batching and Mixing: In compound fertilizer production lines, the Fertilizer Conveying Bucket Elevator transports fertilizer raw materials of different formulations to weighing and batching silos, ensuring precise proportions and preventing stratification or segregation of the mixed materials.

Pre-Packaging Elevation: In the packaging unit, the Fertilizer Conveying Bucket Elevator lifts the mixed fertilizer to an elevated silo for quantitative packaging using an automatic packaging scale. It is suitable for large-batch packaging of 5 to 100 kg.

Finished product conveying and palletizing: Some production lines use elevators to convey the packaged fertilizer bags to the bag sewing machine or palletizing area.

What are the advantages of Fertilizer Conveying Bucket Elevator?

The Fertilizer Conveying Bucket Elevator offers advantages such as efficient transportation, strong durability, environmental safety, flexible configuration, and energy conservation and consumption reduction. Its transport capacity can reach 5-400 tons per hour and its height can reach 60 meters, meeting the needs of different production scales. It is manufactured from wear-resistant and corrosion-resistant materials to adapt to the abrasive and corrosive nature of materials such as chemical fertilizers and organic fertilizers. Its enclosed structure effectively prevents dust from escaping, ensuring a clean and safe working environment. Furthermore, the equipment supports flexible customization of height, hopper capacity, and drive mode to meet diverse production needs. Furthermore, its smooth operation and low energy consumption help reduce long-term operating costs, making it an ideal conveying equipment for fertilizer production, warehousing, and packaging.

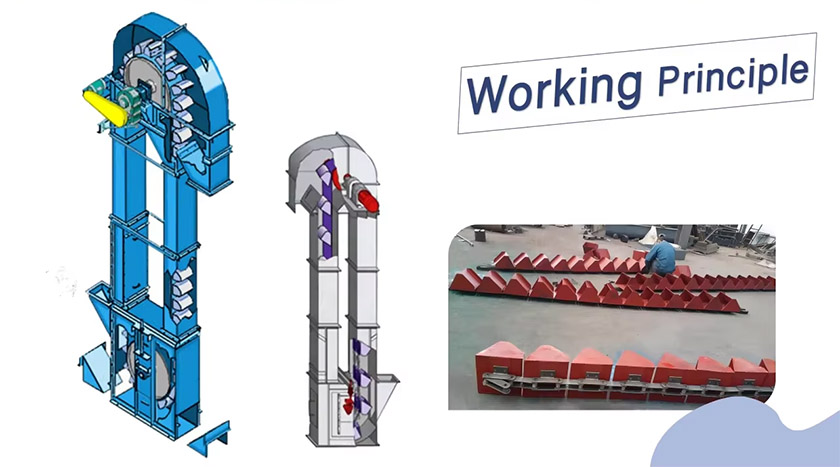

What is the principle of fertilizer conveying bucket elevator?

The Fertilizer Conveying Bucket Elevator operates as follows: First, fertilizer enters the bucket through the bottom feed port; then, the drive device drives the chain or belt to lift the bucket in a vertical or inclined direction; when the bucket reaches the top, the fertilizer is automatically discharged by gravity or centrifugal force; finally, the empty bucket descends to the bottom along the return track, completing a working cycle and starting the next lifting operation.

Fertilizer Conveying Bucket Elevator Parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

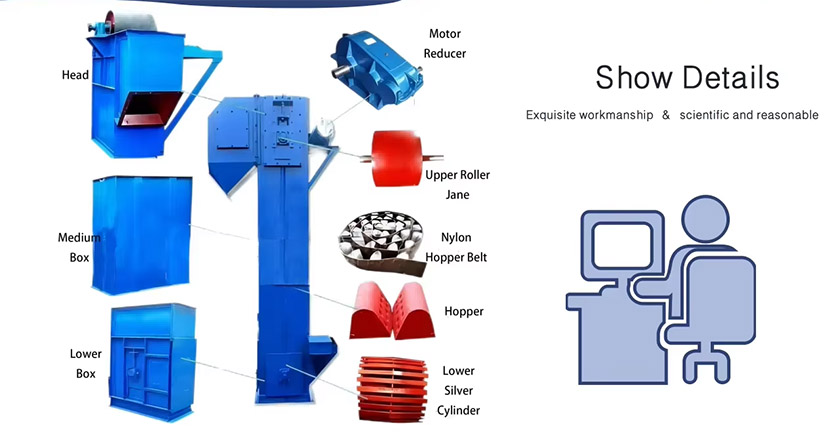

What are the components of the Fertilizer Conveying Bucket Elevator?

The Fertilizer Conveying Bucket Elevator is mainly composed of the following parts: the head includes a drive device, a discharge port and a head roller, which are responsible for power transmission and material unloading; the tail is equipped with a feed port, a tail roller and a tensioning device for material input and chain/belt tensioning adjustment; the bucket is made of wear-resistant material and fixed on a chain or belt to carry and lift fertilizer; the chain/belt is the core transmission component, which not only carries the bucket but also transmits power; the casing adopts a closed design to effectively prevent dust overflow and material leakage; the supporting structure includes columns and beams to ensure the stability and safety of the equipment during operation

Fertilizer Conveying Bucket Elevator Customer Cases

| Cases | Application | Lifting Height | Capacity | Key Features |

| NPK Fertilizer Plant (Large-Scale Production) | Vertical transport of blended NPK granules to packaging line | 25m (from mixing to silo storage) | 50 tons/hour | Abrasion-resistant steel buckets; Dust-proof sealed design; Automatic lubrication system |

| Organic Compost Facility (Eco-Friendly Operation) | Lifting fermented organic fertilizer to drying system | 15m | 30 tons/hour | Corrosion-resistant coating; Gentle handling to maintain granule integrity; Easy-clean design for organic material |

| Urea Granule Storage (High-Capacity Handling) | Transporting urea from production line to storage silos | 40m | 80 tons/hour | Explosion-proof motor (for urea dust safety); Heavy-duty chain drive system; Moisture-proof construction |

How to Select Fertilizer Conveying Bucket Elevator?

When selecting a fertilizer bucket elevator, consider factors such as fertilizer properties, lifting height, required output, and equipment material to ensure efficient and stable operation.

Fertilizer Properties

For dry fertilizers like urea and compound fertilizer, a belt bucket elevator is recommended for smooth operation and low noise.

For moist or corrosive fertilizers like organic fertilizer and humic acid, a chain bucket elevator is recommended, constructed of stainless steel or with an anti-corrosion coating to prevent rust.

Fertilizers prone to caking may require the addition of vibration or cleaning devices to prevent clogging.

Lifting Height and Output

Lifting Height: Bucket elevators typically have a lifting height of 5 to 30 meters. Higher heights require a more powerful drive unit.

Transport Capacity: Bucket capacity and operating speed are selected based on production needs. Small equipment (5 to 10 tons/hour) is suitable for packaging lines, while large equipment (20 to 50 tons/hour) is suitable for continuous conveying on production lines.

Material Options

Casing: Plain carbon steel (suitable for dry fertilizers), stainless steel, or galvanized steel (moisture-resistant and corrosion-resistant).

Bucket: Wear-resistant plastic (for lightweight fertilizers), nylon, or stainless steel (for wet/corrosive fertilizers).

Drive: Chain (heavy-load resistant) or belt (low-noise, economical).

Fertilizer Conveying Bucket Elevator FAQs

What is the main function of a fertilizer conveying bucket elevator?

A fertilizer conveying bucket elevator is primarily used for vertical or inclined conveying of granular and powdered fertilizers, such as compound fertilizer, organic fertilizer, and urea. It uses a bucket to lift fertilizer from the bottom to the top, achieving efficient and continuous material transport. It is widely used in fertilizer production lines, warehousing, and packaging.

How much does a fertilizer bucket elevator cost?

The price of a fertilizer conveying bucket elevator ranges from $350 to $6,800. The specific price depends on the model, lifting height, material, configuration, and customization options. For details, please contact our online customer service or email sales@xxdahan.com.

What should I do if the fertilizer conveying bucket elevator experiences material backflow (fertilizer falling back) during operation?

The return material may be caused by the following reasons: incomplete bucket unloading: adjust the elevator speed or check the bucket installation angle; excessive feeding: control the feeding speed to avoid overloading; belt/chain slippage: check the tensioning device to ensure that the transmission components are normal.

What is the maintenance of fertilizer conveying bucket elevator?

Regular inspection: Check the tension and wear of the chain/belt, and adjust or replace it in time.

Lubrication maintenance: Regularly add lubricating oil to moving parts such as bearings and chains to reduce wear.

Clean up the accumulated materials: Regularly clean the residual materials in the bucket and casing to prevent blockage.

Check the motor: Ensure that the motor is running normally to avoid overheating or overloading.

Anti-rust treatment: Anti-rust treatment is performed on the outer surface of the equipment to extend its service life.

Safety protection: Regularly check whether the safety devices (such as emergency stop switches and protective covers) are normal.