Dry mortar bucket elevator

Thursday November-06 2025 14:37:10

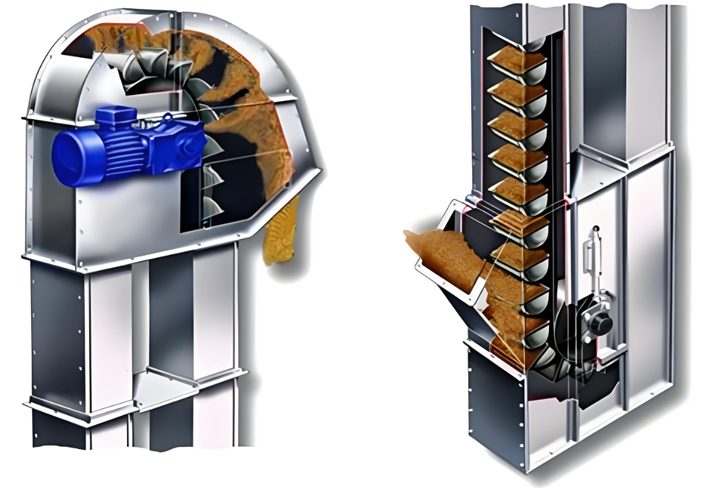

A dry mortar bucket elevator is a type of hoist used to vertically transport dry mortar using a chain or belt-driven bucket. It can transport dry mortar from a low point to equipment at a specified height, such as mixing tanks or storage silos, with a vertical lifting height of up to 50 meters and a capacity of 10-500 m³/h. Dry mortar is a powdery or granular mixture composed of cement, quartz sand, lime powder, sand, and additives. It is dry and moisture-free, prone to dust generation, and its flowability is affected by the material's moisture content. Therefore, a fully enclosed structure is required during lifting to prevent dust leakage. For mortar with poor flowability, a deep bucket is recommended, while a shallow bucket can be used for mortar with good flowability. The bucket capacity should be between 1L and 6L.

Dry mortar bucket elevator video

What are the advantages of a dry mortar bucket elevator?

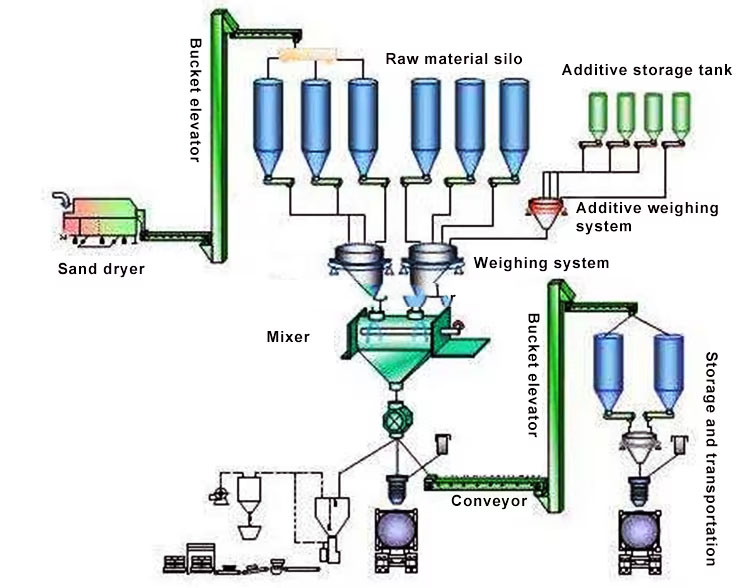

In dry mortar production lines, the Dry Mortar Bucket Elevator is used to lift raw materials from a low-level silo to a high-level mixer. Its vertical lifting capability minimizes floor space and allows for a lifting height of up to 60 meters, making it suitable for dry mortar production lines or mixing plants with limited factory space. The entire machine features a fully enclosed structure, preventing dust leakage and environmental pollution during transport. For materials, the hoppers and cylinders in contact with the materials are made of 304 stainless steel, ensuring corrosion resistance and material cleanliness. The shell can be made of carbon steel to reduce costs. It can transport dry mortar of different particle sizes and moisture content. Both deep and shallow hoppers are available, preventing material sticking and clogging, with a conveying capacity of up to 500 cubic meters. Customized products are also available to suit different applications and materials, such as those equipped with dust collectors to purify dust during transport.

What are the types of dry mortar bucket elevators?

There are four main types of dry mortar bucket elevators: TD belt type, NE plate chain type, TH ring chain type, and TGD steel belt type. They differ in their traction components, lifting height, type of dry mortar being lifted, and conveying capacity. The appropriate type can be selected according to the requirements.

| Model | Traction method | Maximum lifting height | Conveying capacity range | Applicable temperature | Features | Suitable materials |

| TD type Dry mortar bucket elevator | Rubber belt | 40m | 5.4-166m³/h | Ordinary tape ≤60℃, heat-resistant tape ≤120℃) | Smooth operation and low noise | Powdered, small granular non-abrasive or semi-abrasive materials |

| NE type Dry mortar bucket elevator | Plate chain | 40m | 15-800m³/h | ≤250℃ | Good wear resistance and long life | Dry mortar with high abrasiveness |

| TH type Dry mortar bucket elevator | Ring chain | 50m | 35-365m³/h | ≤250℃ | Simple structure, high temperature resistance | High temperature, abrasive materials |

| TGD type Dry mortar bucket elevator | Steel wire tape | 60m | Depending on the model | ≤120℃ | Large lifting height | Dry mortar with high lifting height |

How does a dry mortar bucket elevator work?

The working principle of the bucket elevator for dry mortar is to drive the conveyor belt to move by the motor to drive the reducer to load the bulk material onto the bucket lift. The chain or belt of the bucket lift moves under the drive to lift the bulk material from the bottom to the top. When the material reaches the target height, it is transported to the required position through a conveyor belt or a pipeline.

Dry mortar bucket elevator parameters

TD belt bucket elevator parameters

| Model | Hopper form | Conveying capacity (m³/h) | Bucket width (mm) | Dou Rong (L) | Bucket distance (mm) | Bandwidth (mm) | Bucket speed (m/s) |

| TD160 | Q/ZD/SD | 5.4-16.6 | 160 | 0.5-4.2 | 280 | 200 | 1.4 |

| TD250 | Q/ZD/SD | 9.6-24 | 250 | 0.9-5.9 | 350 | 300 | 1.6 |

| TD315 | Q/ZD/SD | 16-46 | 315 | 1.3-9.4 | 360 | 400 | 1.6 |

| TD400 | Q/ZD/SD | 22-66 | 400 | 1.9-15 | 450 | 500 | 1.8 |

NE plate chain bucket elevator parameters

| Model | Lifting capacity (m/h) | Material allowable block size (mm) |

| NE15 | 16 | 25-65 |

| NE30 | 31 | 40-90 |

| NE50 | 60 | 40-90 |

| NE100 | 110 | 55-130 |

| NE150 | 165 | 55-130 |

| NE200 | 220 | 70-170 |

| NE300 | 320 | 70-170 |

| NE400 | 441 | 90-205 |

| NE500 | 470 | 100-240 |

| NE600 | 600 | 100-240 |

| NE800 | 800 | 110-275 |

What are the applications of Dry mortar bucket elevator?

Dry mortar bucket elevators can be used in dry mortar production lines to lift powder, granules, and other similar bulk materials. They can be used in the building materials industry to lift raw materials such as cement, sand, and additives to the mixer, and also to transport mixed semi-finished mortar to secondary mixing or screening equipment. Qualified dry mortar can also be transported to a high-level finished product silo for storage. They can lift both ordinary and special dry mortars, such as masonry mortar, plastering mortar, floor leveling mortar, premixed mortar, thermal insulation mortar, tile adhesive, self-leveling mortar, repair mortar, and various other types of dry mortar.

Dry mortar bucket elevator customer case

| Application Scenarios | Lifting Materials | Lifting Height | Lifting Capacity |

| Raw Material Conveying in a Dry Mortar Production Line in Vietnam | Dry Sand (Moisture Content <0.5%) | 12 meters | 18 tons/hour |

| Finished Product Storage of a 300,000-ton/year Production Line in Europe | Ordinary Masonry Mortar (M5-M15) | 18 meters | 25 tons/hour |

| Special Mortar Production of a Building Materials Factory in India | Tile Adhesive Containing Latex Powder and Cellulose Ether | 10 meters | 8 tons/hour |

| Ground Leveling Project of an Engineering Project in China | Ultra-High Performance Self-Leveling Mortar (C25) | 15 meters | 12 tons/hour |

Dry Mortar Bucket Elevator Manufacturer

Dahan Dry Mortar Bucket Elevator Manufacturer produces various models of elevators for dry mortar production lines, including belt conveyors, plate chains, and ring chains. These elevators can lift bulk powdery and granular materials such as cement, sand, and stone from low to high places, with heights ranging from 3 to 50 meters and lifting capacities from 5 to 500 cubic meters. Factory direct sales are available, with prices ranging from $400 to $6800. Materials include carbon steel and stainless steel; stainless steel is required for conveying corrosive materials. Customized products or additional functions are also supported depending on the type of material being lifted, such as mobile, explosion-proof, high-temperature resistant, and cooling models.

Recommend Product

- Dry Mortar Bucket Elevator

- Quartz sand bucket elevator

- Belt Type Bucket Elevator

- TH Chain Bucket Elevator