Dry Mortar Bucket Elevator

It can be used to vertically transport dry mortar, putty powder, insulation mortar and other similar bulk materials. The price range is $300-$9800.

| Lifting height | 50m |

| Conveying capacity | 10-300 t/h |

| Hopper width | 160-1600 mm, a variety of specifications are available. |

| Motor power | 5-50 kW. |

| Bucket Material | Options include carbon steel, stainless steel, or reinforced plastics for enhanced durability. |

What is the Dry Mortar Bucket Elevator?

The Dry Mortar Bucket Elevator is a bucket elevator used to lift various types of dry mortar (such as masonry mortar, plaster mortar, insulation mortar), premixed mortar, powder and similar bulk materials from low to high positions. It overcomes vertical space limitations and smoothly lifts materials from low locations (such as the mixer outlet and the bottom of the storage silo) to high locations (such as the top of the finished product silo, the packaging machine entrance or the mixing plant), saving space and improving production efficiency. It can reach a height of 60 meters and can lift 300 tons of dry mortar per hour.

To address the abrasive nature of dry mortar, the Dry Mortar Bucket Elevator's body is available in carbon steel and stainless steel, and the hopper is available in ultra-wear-resistant engineering plastics (such as polyethylene PE and polypropylene PP) or food-grade/corrosion-resistant stainless steel (such as 304 and 316). You can choose the appropriate material based on the characteristics of the dry mortar being transported, and we also support customization.

What are the applications of Dry Mortar Bucket Elevator?

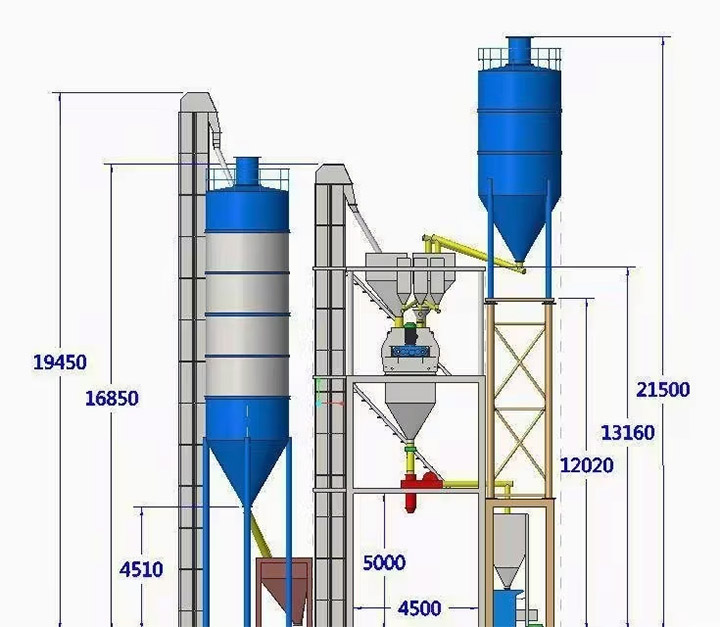

The Dry Mortar Bucket Elevator is commonly used in dry-mix mortar production lines, ready-mix mortar plants, insulation material plants, and building materials factories, ensuring smooth material transfer between mixing, storage, and packaging.

Raw material handling: Cement, fly ash, sand, and other basic powders are lifted from the bottom storage silo to a high-level batching scale or premixing equipment.

Mixing: The Dry Mortar Bucket Elevator vertically transports evenly mixed dry mortar from the bottom of the mixer to the top of the finished product buffer, preventing material stratification and ensuring consistent finished product quality.

Packaging and loading: Finished mortar can be stably lifted from the buffer to a high-level packaging machine. During bulk loading, it can be quickly loaded with tank trucks, improving shipping efficiency.

Why Choose a Bucket Elevator for Dry Mortar?

The Dry Mortar Bucket Elevator's vertical conveying system allows materials to be lifted to considerable heights with minimal space requirements, reaching heights of 5-60 meters and a conveying capacity of 5-300 m³/h. Its sealed, dust-proof design prevents dust leakage, and the gentle bucket motion minimizes particle breakage, maintaining mortar quality and easily meeting the needs of production at varying scales. The wear-resistant hopper (PE, nylon, or metal) reduces material residue and improves efficiency. It is widely used in production lines for dry-mix mortar, putty powder, and insulation mortar, as well as in the chemical and grain processing industries, enabling automated and continuous production, reducing labor costs, and improving production stability. Its reliable operation and easy maintenance make it an ideal choice for powder conveying.

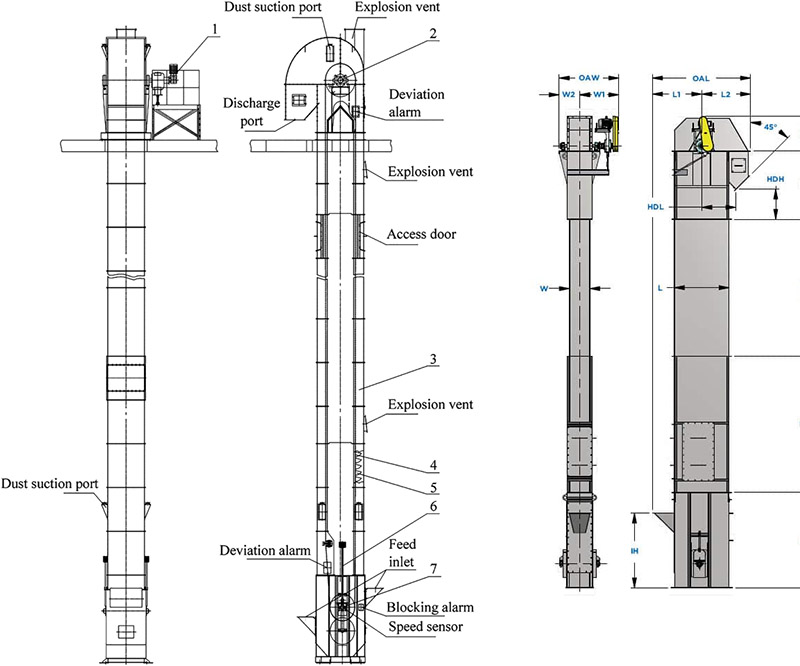

How does the Dry Mortar Bucket Elevator work?

The Dry Mortar Bucket Elevator drives the chain to rotate through the motor, so that the bucket circulates in the frame. During the lifting process, the dry mortar enters the bucket from the storage bucket, is lifted to the top with the chain, bypasses the top wheel and flips downward, and the material is poured into the receiving trough.

Dry Mortar Bucket Elevator Parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper type | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Conveying volume (m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width (mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong (L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance (mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth (mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed (m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Material quantity (mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Conveying capacity (m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width (mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong (L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance (mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth (mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed (m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Material quantity (mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

What are the structures of Dry Mortar Bucket Elevator?

Buckets: Designed for minimal spillage and smooth material flow.

Belt or Chain: Chosen based on material type, capacity, and lifting height.

Head Pulley & Boot Pulley: Drive and return pulleys to guide the belt or chain.

Enclosed Casing: Provides dust containment and improves operational safety.

Tensioning System: Ensures proper alignment and tension control to avoid slippage.

Dry Mortar Bucket Elevator customer case

| Application scenario | Lift height | Lift capacity | Features |

| A large dry mortar production plant, used to lift the mixed finished mortar to the packaging warehouse. | 15 meters | 30 tons/hour | The equipment runs stably, has good sealing, and no dust leakage. When used with an automatic packaging machine, the production efficiency is increased by 40%. |

| A building materials company's tile adhesive production line, used to lift dry mortar from the mixer to the buffer bin. | 10 meters | 20 tons/hour | Good wear resistance, adaptable to high-load operation, reducing labor feeding costs, and low failure rate. |

| A certain energy-saving building materials company, used to lift lightweight insulation mortar to the mixing system. | 8 meters | 15 tons/hour | Compact structure, small footprint, suitable for installation in small spaces, low operating noise, and easy maintenance. |

What is the Dry Mortar Bucket Elevator Price?

Dry Mortar Bucket Elevators typically cost between $300 and $9,500, depending on the model, material, and configuration. Small carbon steel models (such as the TH series) cost approximately $700–$2,000, while larger stainless steel models (such as the NE series) can cost $3,000–$5,500.

Material: Stainless steel (such as 304) is 2–3 times more expensive than carbon steel.

Lifting height (5–60 meters): The cost increases by $35–$200 per additional meter.

Capacity (15–800 m³/h): Higher capacity increases the price.

Drive power (0.75–22 kW) and accessories (such as wear-resistant chains and seals) also affect the final price. Customization requirements (such as dustproofing and high-temperature resistance) and brand premiums may further increase the cost.

How to choose Dry Mortar Bucket Elevator?

When selecting a dry mortar bucket elevator, consider the following:

Material Characteristics: Assess abrasiveness, moisture content, and particle size to select appropriate bucket material and belt design.

Throughput Requirements: Choose an elevator with sufficient capacity to meet production demands.

Height Constraints: Ensure the system’s lifting height aligns with your facility’s design.

Maintenance Access: Opt for models with easy-access panels for cleaning and maintenance.

Environmental Considerations: Select dust-sealed designs for improved workplace safety and cleanliness.