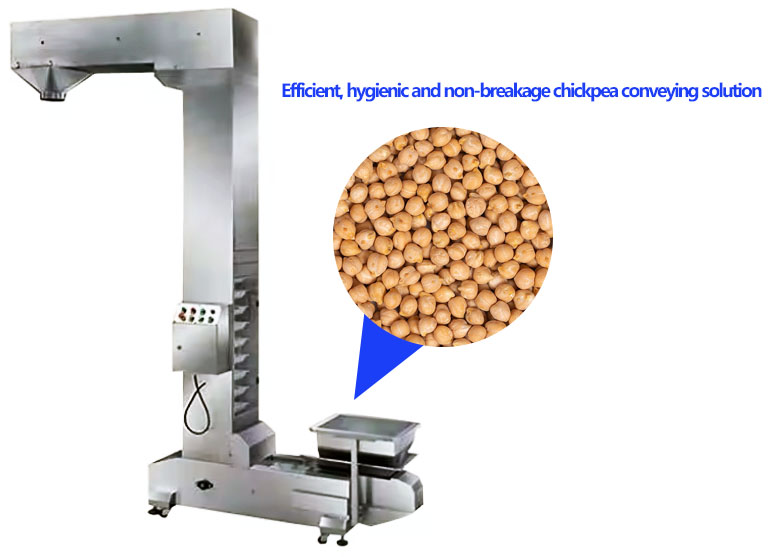

Dried chickpeas Z Bucket Elevator

Thursday October-30 2025 15:25:50

The Dried Chickpeas Z Bucket Elevator is a type of elevator used for lifting dried chickpeas or similar bean materials during processing, storage, and packaging. Because dried chickpeas are dry, granular, and fragile, a gentle, low-speed, and breakage-resistant Z Bucket Elevator is selected for conveying. It employs a horizontal-vertical-horizontal Z-shaped conveying trajectory, lifting the dried chickpeas from a low position to a high position via buckets fixed to a chain. This allows for gentle, low-damage transfer of dried chickpeas between different levels or workstations. The horizontal conveying length is 3-20 meters, the lifting height is 2-30 meters, and the hourly lifting capacity is 5-50 tons.

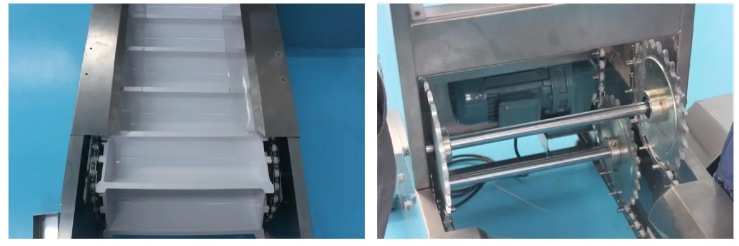

The Dried Chickpeas Z Bucket Elevator can transport regular dried chickpeas, peeled dried chickpeas, and dried chickpeas graded by different particle sizes. Depending on the type of dried chickpeas being lifted, shallow hoppers and curved hoppers are available, which can reduce the breakage rate of dried chickpeas during transport. The entire machine adopts a sealed structure to prevent dust, impurities, and pollution. It is available in carbon steel and stainless steel.

Dried Chickpeas Z Bucket Elevator Video

What are the advantages of the Dried Chickpeas Z Bucket Elevator?

The Dried Chickpeas Z Bucket Elevator features a Z-shaped layout, enabling vertical lifting and horizontal conveying of dried chickpeas. It can transport dried chickpeas from ground-level silos to higher storage tanks, or transfer them between different floors. This layout is suitable for factories with complex structures, significantly saving space. It uses a hopper to scoop material; this flexible handling method minimizes impact force when in contact with the dried chickpeas. Combined with low-speed operation, this effectively reduces breakage and ensures material integrity. The fully enclosed body with smooth inner walls eliminates dead corners, reducing material residue and meeting food hygiene requirements. Furthermore, it can support multi-point feeding or unloading according to the needs of the application site, and supports customized dimensions, hopper capacity, motor configuration, and other parameters.

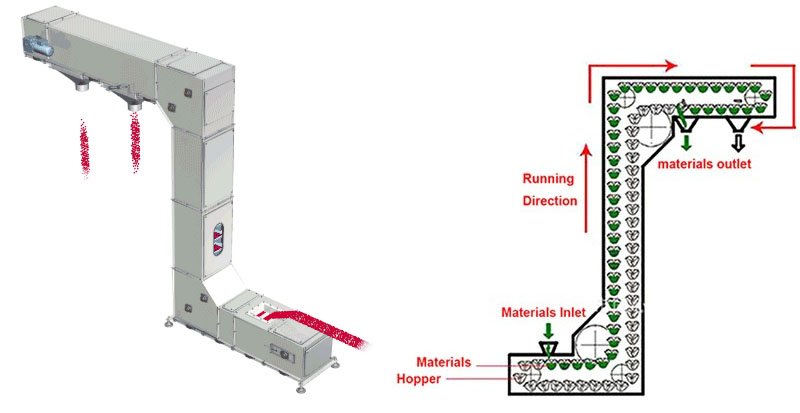

How does the Dried chickpeas Z Bucket Elevator work?

When the Z Bucket Elevator is working, the dry chickpeas enter from the lower feed port. A series of hoppers are fixed at equal intervals on the chain or belt. Driven by the drive device, the hoppers pick up the materials from the feed port and lift them upward along a closed vertical or inclined track. When the hopper runs to the upper discharge port, due to gravity or centrifugal force, the dry chickpeas will be discharged from the hopper and enter the next process or designated location. The entire lifting process is smooth and continuous, ensuring that the dry chickpeas are not squeezed or collided during the transportation process.

Dried Chickpeas Z Bucket Elevator Specifications

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

What are the applications of Dried chickpeas Z Bucket Elevator?

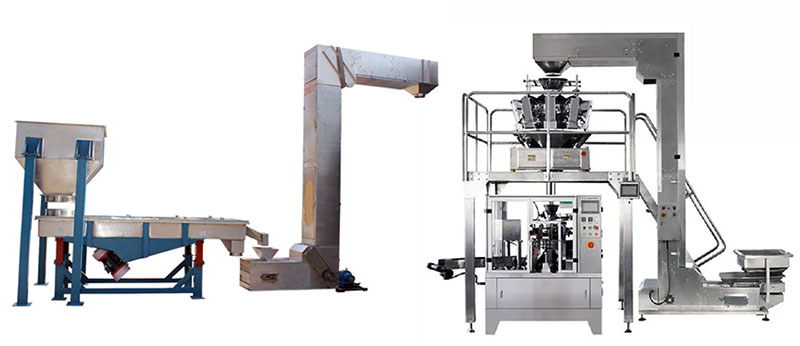

The Dried Chickpeas Z Bucket Elevator is primarily used in the processing, storage, and packaging of dried chickpeas to vertically lift them from a low position to a high position. It can be used to lift whole, broken, or uniformly sized dried chickpeas with a particle size of 0.1-50mm. In raw material lifting, it can raise dried chickpeas from the raw material warehouse or the ground to the feed inlet of processing equipment, achieving automatic raw material supply. During the processing of dried chickpeas, it can transport dried chickpeas from one process step to the next. In finished product packaging, it can lift processed dried chickpeas to packaging machines or storage equipment for subsequent packaging and storage operations.

Dried chickpeas Z Bucket Elevator Customer Case

| Application scenario | Lift height | Lift capacity | Features |

| Xinjiang Agricultural Technology Co., Ltd.: Dried chickpea particles are transported from the pre-treatment workshop to the feed port of the grinder. | 8 meters | 5 tons/hour | Using 304 stainless steel and equipped with PP plastic hopper to prevent the beans from being damaged and ensure food-grade hygiene standards. This production line is mainly used to produce chickpea instant drink powder, crispy beans and other products. The elevator maintains the integrity of the material during the transportation process and reduces dust spillage |

| A certain Indian biotechnology company uses it to lift the roasted chickpeas from the cooling area to the automatic packaging machine silo. | 6 meters | 3 tons/hour | Using a Z-type bucket elevator with a dustproof sealing structure to prevent the beans from getting wet. The equipment runs stably, adapts to the needs of automated production, supports multi-point unloading, and meets the feeding needs of different packaging lines. |

| A large food processing plant in the United States uses it to lift the screened dry chickpeas from the storage area to the color sorter feed port. | 10 meters | 8 tons/hour | It uses carbon steel spray-coated shell, wear-resistant chain, and is equipped with variable frequency speed regulation function to meet the transportation needs of different batches of materials. The equipment runs with low noise and meets the environmental protection requirements of food processing workshops. |

What equipment can the Dried Chickpeas Z Bucket Elevator be used with?

In storage, pre-processing, deep processing, and packaging stages, the Dried Chickpeas Z Bucket Elevator can connect to silos and pre-processing equipment such as screening machines to achieve size grading of dried chickpeas, remove impurities and fragments, and transport the sieved dried chickpeas to the processing stage. It can also be used with weighing and batching systems for multi-point feeding, or connected to packaging machines to complete the packaging and transportation of finished products, improving packaging efficiency.

How to choose Dried chickpeas Z Bucket Elevator?

When selecting a Dried Chickpeas Z Bucket Elevator, it's essential to consider the properties of the dried chickpeas, their material, hopper capacity, lifting height, and lifting capacity. For dried chickpeas with skins, ensure the equipment is airtight to prevent dust generation. For peeled or broken chickpeas, choose a gentle, scratch-resistant conveyor structure to avoid breakage. Food-grade 304 stainless steel is generally preferred for its cleanliness, hygiene, and ease of cleaning, preventing corrosion from starch and protein residues in the dried chickpeas. For hopper capacity, shallow hoppers are recommended for 2-3mm chickpeas to prevent leakage, while deeper hoppers are needed for 4-5mm chickpeas. The lifting height should be between 2-30 meters, determined by the workshop's vertical layout, with sufficient space for maintenance. The lifting capacity can be selected based on the production standards for dried chickpeas, typically ranging from 5-50 tons per hour.