Continuous Bucket Elevator

Various bulk materials are transported upward in a closed casing through continuously arranged hoppers

| Delivery volume | 1500m³/h |

| Maximum lifting height | 50m |

| Applicable material size | ≤150mm |

| Motor power | 75kW |

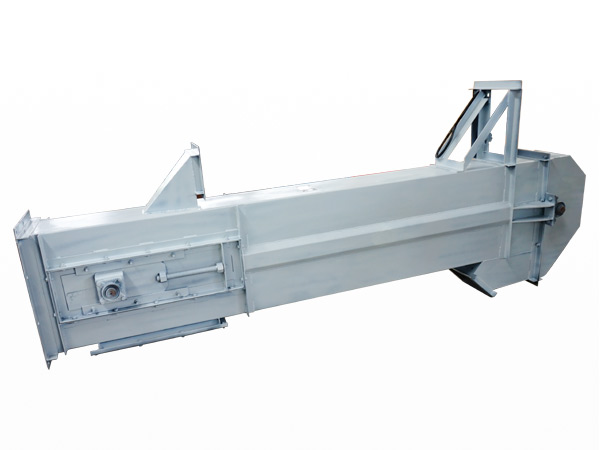

| Overall dimensions | 4800×1600×1800mm |

What is Continuous Bucket Elevator?

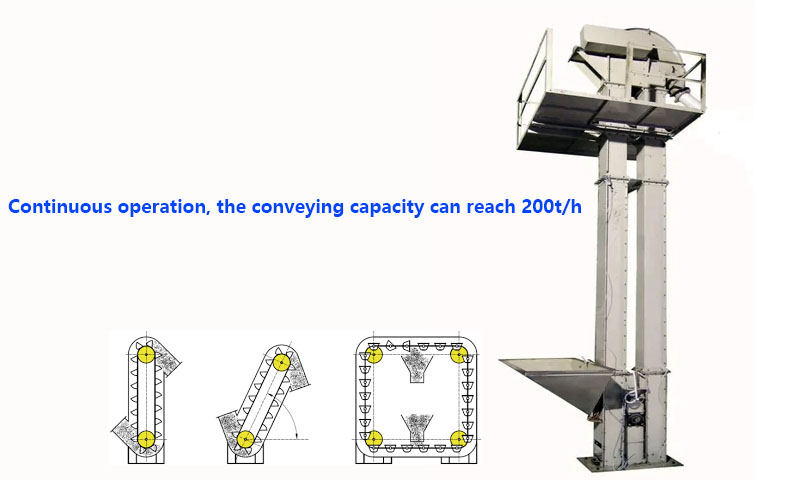

Continuous Bucket Elevator is an automated device that realizes continuous vertical conveying by pulling the bucket with an endless chain or belt. It is designed for handling dry, loose or sticky materials (such as cement, coal, sand and gravel). Its core advantage is that it can convey materials without interruption, which can avoid material accumulation or blockage. It is especially suitable for industrial scenarios with high output and long distance (up to 350 meters).

What types of continuous bucket elevators are there?

Continuous bucket elevators can be divided into plate chain type and belt type according to the traction components and applicable scenarios

Plate chain type continuous bucket elevator (such as NE series): uses high-strength plate chain as the traction component, suitable for vertical transportation of abrasive and blocky materials, such as limestone, cement clinker, etc. Its characteristics are large conveying capacity (up to 1500m³/h), long service life (8-10 years), and can adapt to high temperature environment (material temperature ≤250℃).

Belt type continuous bucket elevator (such as TD series): uses rubber belt or wire rope core belt as the traction component, suitable for conveying dry, loose powder or small granular materials, such as grain, fertilizer, etc. Its advantages are stable operation, low noise and low maintenance cost.

What are the advantages of Continuous Bucket Elevator?

Continuous operation: non-intermittent hopper arrangement, conveying efficiency increased by more than 30%, and the maximum processing capacity reached 200t/h.

Low wear design: the hopper is made of wear-resistant steel plate or polymer material, and the service life is extended by 50%; the GTD series tape has its own correction function to reduce the maintenance frequency.

Sealed and environmentally friendly: fully enclosed casing structure, dust overflow rate <0.5%, in line with ISO14001 environmental protection standards.

Intelligent control: equipped with material level sensor and speed controller, support automatic start and stop and fault warning.

Flexible adaptation: lifting height 5-350 meters can be customized, support gravity/screw dual tensioning system, adapt to different working conditions

How does the Continuous Bucket Elevator work?

The working principle of the Continuous Bucket Elevator can be summarized as a "loading-lifting-discharging" cycle. The material naturally falls into the hopper through the inflow feed port, without the need for the hopper to actively dig, reducing material damage and equipment wear. The plate chain or belt drives the hopper to rise at a low speed. The material is tightly piled under the action of gravity to avoid spilling. After reaching the top, the hopper bypasses the sprocket or roller, and the material is naturally discharged into the discharge port under the action of gravity. The discharge angle can be precisely controlled by adjusting the sprocket speed.

What are the applications of Continuous Bucket Elevator?

Building materials industry: Vertical transportation of clinker in cement plants, with 40% efficiency improvement.

Coal industry: Continuous lifting of raw coal from coal washing plants to sorting equipment to avoid blockage risks.

Chemical industry: Dust-free transportation of fertilizer particles to reduce material breakage rate.

Port logistics: Rapid loading of grain at bulk cargo terminals, supporting 24-hour continuous operation

Continuous Bucket Elevator Customer Cases

A cement plant uses NE1500 plate chain elevator to transport cement clinker, with a daily transportation capacity of 3,000 tons, which reduces energy consumption by 40% and maintenance costs by 60% compared with traditional centrifugal elevators.

A grain processing plant installed TD series belt elevators to process wheat, with operating noise below 70 decibels and material crushing rate below 0.5%, fully meeting food-grade production requirements.

A chemical company uses NBH high-speed elevators to transport powdered raw materials, with a transportation speed of 90m/min, realizing automated material feeding in the workshop and reducing labor costs by 70%.

Continuous Bucket Elevator vs Centrifugal Bucket Elevator

| Comparison items | Continuous bucket elevator | Centrifugal bucket elevator |

| Discharging method | Gravity/mixed discharge, suitable for sticky and wet materials | Centrifugal discharge, only suitable for dry and loose materials |

| Operation continuity | Uninterrupted continuous conveying, high efficiency | Intermittent conveying, easy to produce material accumulation |

| Applicable height | 5-60 meters (customizable ultra-long distance) | Usually ≤40 meters |

| Maintenance cost | Low wear design, low maintenance frequency | Hopper and traction parts are easy to wear, high maintenance cost |

| Typical applications | Building materials, metallurgy, chemical heavy-duty scenarios | Food, light industry small particle material transportation |

Centrifugal Bucket Elevator

Centrifugal Bucket Elevator