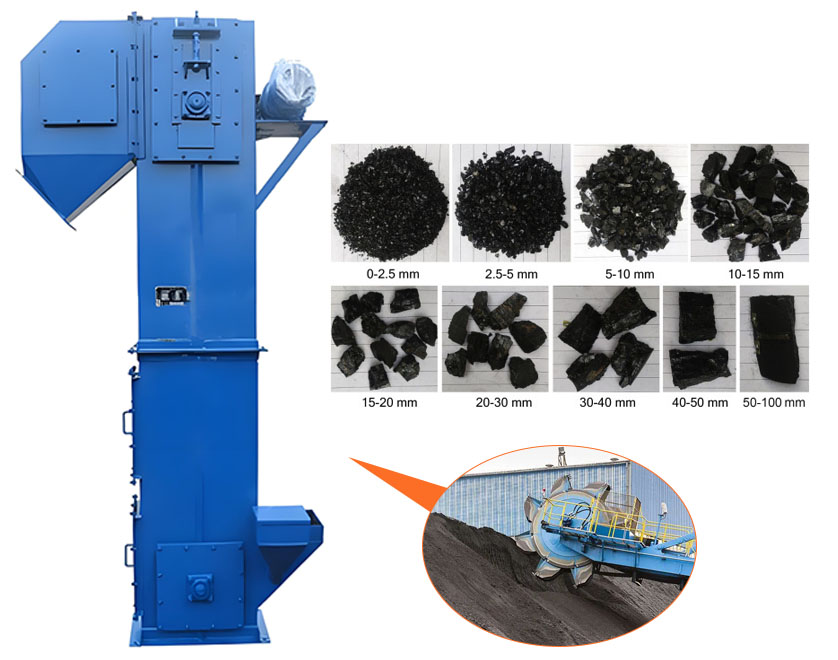

Coal Conveying Bucket Elevator

A device used to lift bulk materials such as coal vertically from a low location to a fixed height; price range: $350-$7,600.

Lifting height: 5-60 meters

Conveying capacity: 50-800 t/h

Bucket capacity: 5-50 liters

Operating speed: 0.8-2.5 m/s

What is Coal Conveying Bucket Elevator?

Coal Conveying Bucket Elevator is a bucket elevator used to lift bulk materials such as coal and coke vertically or obliquely. It lifts coal from a low place to a high place through a bucket fixed on a chain or belt. The lifting height is 5-60 meters and the maximum lifting capacity can reach 800 tons per hour. It is widely used in coal, electric power, metallurgy, chemical industry and other industries.

Moreover, compared with ordinary conveyors, the Coal Conveying Bucket Elevator transports materials vertically, occupies a small area, and is suitable for use in places with limited space. It has the characteristics of high efficiency, stability, and good sealing, and can meet the needs of large-scale coal transportation.

What is Coal Conveying Bucket Elevator used for?

The main purpose of the Coal Conveying Bucket Elevator is to transport coal, coal powder, and other coal-like bulk materials vertically or inclined, including:

Coal transportation: lifting coal from the ground or coal storage yard to high coal storage bins, boilers or conveying equipment.

Coke transportation: in the metallurgical industry, it is used for the lifting and transportation of coke.

Other bulk materials: vertical transportation of materials such as ore, limestone, gypsum, etc.

What industries is Coal Conveying Bucket Elevator used in?

Coal Conveying Bucket Elevator is an indispensable equipment in coal transportation. It can transport coal from one location to another. It is often used in the transportation, loading, unloading and storage of materials similar to coal in the coal industry, electric power, metallurgy, chemical industry, building materials and other industries.

Coal Industry: Used for coal transportation in coal mines, coal washing plants, thermal power plants and other places.

Power Industry: Used for coal lifting in coal-fired power plants to transport coal to boilers for combustion.

Metallurgical Industry: Used for lifting and conveying materials such as coke and ore.

Chemical Industry: Used for the transportation of coal chemical raw materials.

Building Materials Industry: Used for the lifting of building materials such as limestone and gypsum.

What are the advantages of Coal Conveying Bucket Elevator?

Coal Conveying Bucket Elevator can be used to vertically lift various types of coal. Vertical transportation is not restricted by space, with high transportation efficiency, large conveying capacity, good sealing, no dust leakage, and strong adaptability. Customized transportation solutions can be provided according to application scenarios or materials.

Efficient transportation: It can continuously and stably transport large amounts of coal, with a lifting height of 60 meters.

Good sealing: It adopts a closed structure to reduce the spillage of coal dust and meet environmental protection requirements.

Strong adaptability: It can transport coal of different particle sizes and humidity and adapt to various working conditions.

Compact structure: It occupies a small area and is suitable for places with limited space.

Smooth operation: It adopts chain or belt drive, which runs smoothly and has low noise.

How does Coal Conveying Bucket Elevator work?

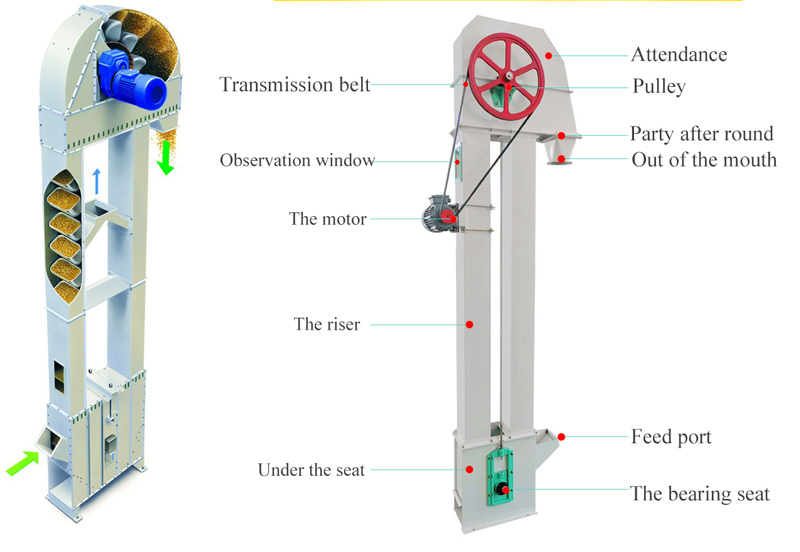

A Coal Conveying Bucket Elevator works by using a continuous loop of buckets attached to a belt or chain to vertically lift bulk coal. The coal is fed into the elevator's boot (bottom section), where the buckets scoop it up. As the belt/chain rotates, the loaded buckets travel upward, discharge coal at the top through centrifugal or gravity force, then return empty to repeat the cycle. Key components include drive motors, tensioning systems, and dust-proof enclosures to ensure efficient, enclosed coal transport for industries like power plants and mining.

What components does Coal Conveying Bucket Elevator consist of?

The Coal Conveying Bucket Elevator consists of the following main components:

Head and tail sections: Contains the drive unit (motor, reducer, etc.), rollers (drive/guide), inlet/discharge ports, and tensioning device.

Bucket: Made of wear-resistant material, fixed to the traction member to carry the material.

Traction member: A chain (heavy load) or belt (light load, high speed) drives the bucket in a circular motion.

Casing: Enclosed steel plate structure lined with wear-resistant material for dust and environmental protection.

Support structure: Columns and crossbeams ensure stability.

Safety devices: Include speed monitoring, anti-reverse rotation, and an emergency stop switch to ensure safe operation.

Control system: Electrical cabinet (start/stop speed control) and sensors (monitoring operating status).

Coal Conveying Bucket Elevator Customer Case

| Case | Application scenario | Lifting height | Lifting amount | Key features |

| Coal mine to power plant: | Used to transport coal mined from coal mines vertically to the coal storage bunker of power plant boilers to optimize the fuel supply process | 30m | 200 t/h | Using heavy-duty chain traction, wear-resistant and high-temperature resistant, suitable for long-term continuous operation; equipped with dust-proof sealing design to reduce dust pollution during coal transportation |

| Port loading and unloading | Used for port coal loading and unloading, lifting bulk coal from cargo ships to conveyor belts, and then transferring to storage areas | 25m | 150 t/h | NE series adapts to high humidity environments to prevent coal agglomeration; low failure rate design, suitable for high-intensity operations |

| Coking plant pretreatment | Used for lifting and grading coal before coking in coking plants to ensure the quality of coke | 40m | 100 t/h | High temperature resistant chain (can withstand 250°C), low breakage rate |

How to Select Coal Conveying Bucket Elevator?

Selecting the right coal conveying bucket elevator requires analyzing coal characteristics, lifting height, capacity, motor configuration, and operating conditions. The following is a structured approach:

Coal Characteristics

| Property | Impact on Selection | Recommended Solution |

| Moisture Content | Wet coal may clog; dry coal generates dust | → Sealed design (NE-type) for dust prevention; anti-clogging buckets |

| Particle Size | Lumps vs. fines affect bucket filling efficiency | → Deep buckets for lumps; scoop-type for fines |

| Abrasiveness | Coal with high silica wears buckets/chains faster | → Wear-resistant steel buckets + hardened chains |

| Temperature | Hot coal (e.g., from drying) requires heat resistance | → Heat-resistant chains (TH-type, up to 250°C) |

Lifting Height

| Height Range | Suitable Elevator Type | Key Considerations |

| < 20m | Belt-driven (TD-type) | Low power, cost-effective |

| 20–40m | Chain-driven (NE-type) | Balanced strength & speed |

| > 40m | Heavy-duty chain (TH-type) | Reinforced structure to handle load |

Note: Taller elevators need intermediate bearings to prevent belt/chain sagging.

Capacity

| Capacity | Bucket Size & Speed | Motor Power (Example) |

| < 50 t/h | Small buckets, 1–1.2 m/s | 7.5–15 kW |

| 50–200 t/h | Medium buckets, 1.5 m/s | 18.5–45 kW |

| > 200 t/h | Large buckets, 2 m/s | 55–110 kW |

Formula:

Motor Power (kW)≈Capacity (t/h)×Height (m)60×Efficiency (0.7–0.8)

Motor Power (kW)≈60×Efficiency (0.7–0.8)Capacity (t/h)×Height (m)

Motor Configuration

| Requirement | Motor Type | Advantages |

| Standard duty | 4-pole AC motor | Reliable, low maintenance |

| Variable speed | VFD-controlled motor | Adjust flow to match demand |

| Harsh environments | Explosion-proof (Ex d) | Safe for coal dust zones |

| High torque | Gearmotor + reducers | Smooth start for heavy loads |

Summary: Coal Bucket Elevator Selection Table

| Factor | TD-Type (Belt) | NE-Type (Chain) | TH-Type (Heavy Chain) |

| Best For | Dry, fine coal | General-purpose | Abrasive/hot coal |

| Max Height | ≤30m | ≤50m | ≤60m |

| Max Capacity | 150 t/h | 300 t/h | 200 t/h (high-temp) |

| Maintenance | Low | Moderate | High (chain wear) |