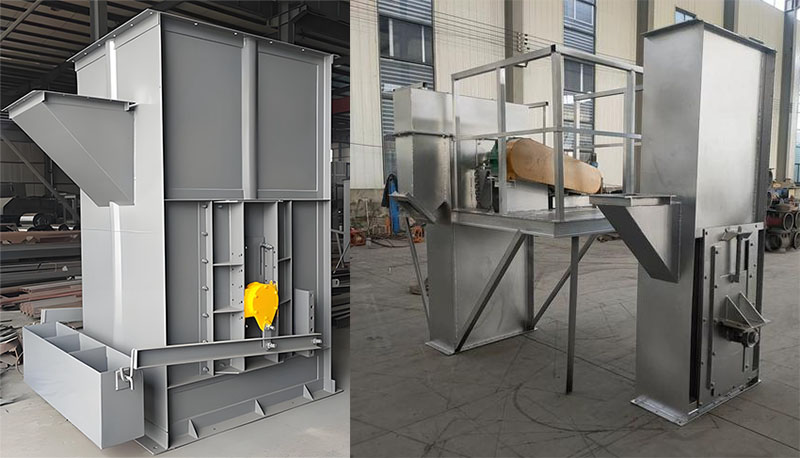

Chain bucket elevator in mining industry

Friday December-05 2025 16:39:59

Chain bucket elevator in mining industry can vertically lift powdered, granular, and lumpy materials such as coal and ore from low to high places. They use a ring chain bucket to transfer materials from the mine to the processing plant. The lifting height is 5-60 meters, and the lifting capacity ranges from 10 m³/h for small models to 500 m³/h for heavy models. The casing and chain are made of Q235 carbon steel, which has high strength and can operate stably even under harsh working conditions with high loads. The casing is designed to be fully enclosed to reduce dust pollution.

Chain bucket elevator in mining industry comes in various bucket capacities, including 1L, 2L, 3L, 4L, 5L, and 6L. These include shallow buckets, deep buckets, scale buckets, and guide trough buckets. The appropriate bucket can be selected based on the properties of the material being lifted. Deep buckets are suitable for materials with poor flowability and a tendency to clump, while shallow buckets are suitable for granular materials with good flowability. For large materials, guide trough buckets can be selected to prevent jamming. For corrosive materials, stainless steel materials should be chosen.

What types of Chain bucket elevators in mining industry are there?

Chain bucket elevators in mining industry are mainly of two types: ring chain and plate chain. They differ slightly in the materials they lift and the scenarios in which they are used.

Ring Chain bucket elevators in mining industry: These use ring chains as the traction device, capable of withstanding the impact of large pieces of ore. They have a relatively simple structure, are relatively inexpensive, and can withstand temperatures up to 250℃. They are suitable for powdery, granular, and small-lump materials with little or no abrasiveness.

Plate Chain bucket elevators in mining industry: These use plate chains spliced from steel plates. They are high-strength, not easily deformed, and have a strong load-bearing capacity. They can be used for heavy-duty, high-capacity transport of medium to large-lump and highly abrasive materials, with a conveying capacity of up to 500m³.

What are the advantages of chain bucket elevators in the mining industry?

Chain bucket elevators in the mining industry utilize durable, wear-resistant alloy steel chains with high load-bearing capacity. For corrosive conveying applications, an anti-corrosion coating is added to the chain surface to extend service life. Large-capacity hoppers up to 6L are used, with a conveying capacity of 10-500m³ per hour. Suitable for everything from small-scale mining to large-scale mining plants, the equipment material, hopper type, size, and motor power can be customized based on the properties of the materials being conveyed. For materials with high dust levels, in addition to a closed structure, a dust collection device can be added, providing double-layer protection to ensure the working environment remains uncontaminated.

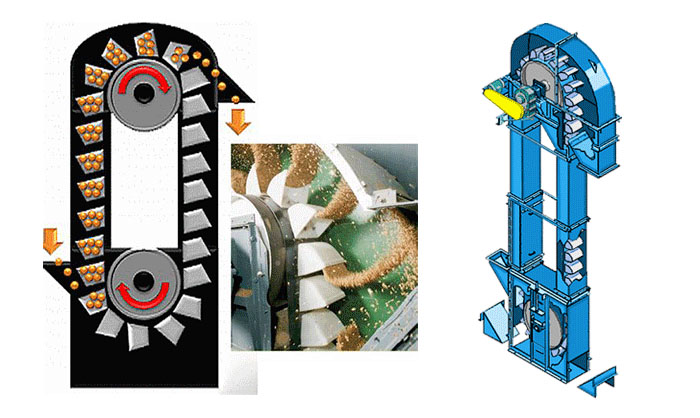

How does a Chain bucket elevator in mining industry work?

When operating, the Chain bucket elevator in mining industry goes deep into the mine's silo or crushing station to catch the lumpy or granular ore that hasn't been finely screened after mining. A high-strength chain pulls a wear-resistant bucket, scooping up the ore from the bottom and lifting it vertically upwards along the inner wall of the machine casing. The lifting process is done within a sealed casing, preventing mine dust and material spillage. Once at the top, the bucket rotates with the chain, and under the combined force of gravity and centrifugal force, the material is precisely unloaded into subsequent processing equipment. The empty bucket then returns to the bottom from the other side to continue processing.

Parameters of Chain Bucket Elevator in Mining Industry

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

What are the applications of Chain bucket elevator in mining industry?

Chain bucket elevators in mining industry are used for vertically lifting powdery, granular, and lumpy materials in mining production. They can be used for conveying lumpy fuels such as raw coal and coking coal, medium-hard ore particles such as iron ore and copper ore, and powdery materials such as concentrate powder, roasted ore powder, and tailings sand after flotation in scenarios such as raw coal hoisting in mines, ore and tailings transportation in ore dressing plants, and concentrate transfer in metallurgical mines. When in use, they can be paired with vibrating feeders to achieve uniform feeding, connected with jaw crushers and circular vibrating screens to complete the lifting and transfer of crushed and screened materials, and can also be used with belt conveyors and bucket loaders to form a complete conveying and processing production line from the mining site to the storage silo or processing workshop.

Chain bucket elevator in mining industry customer case

Recommend Product

- Chain Bucket Elevator

- TH Chain Bucket Elevator

- NE Plate Chain Bucket Elevator

- TH type chain bucket elevator