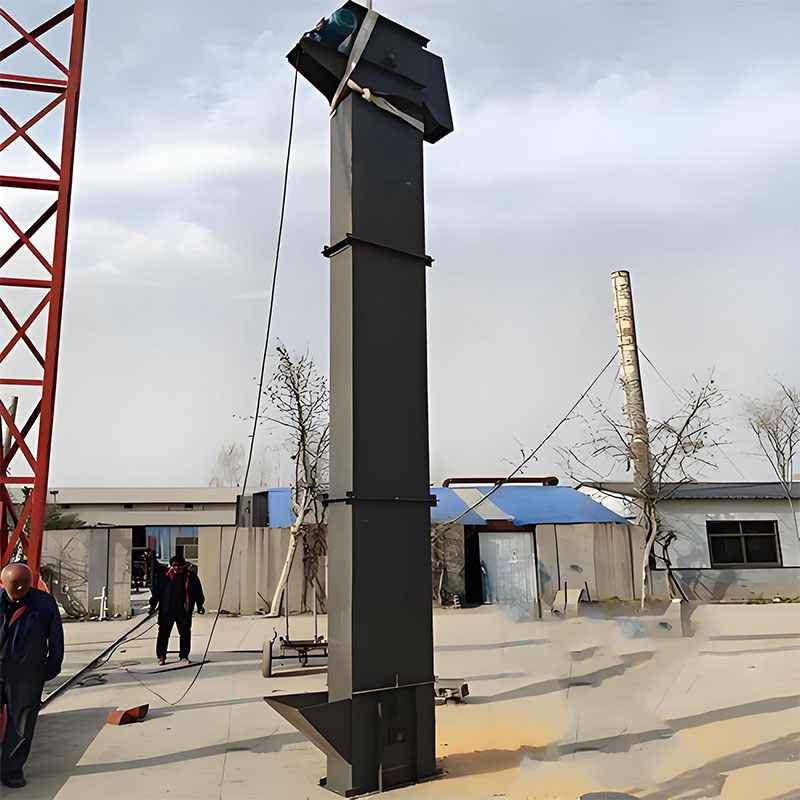

Chain bucket elevator for fertilizer

Thursday December-04 2025 15:29:31

Chain bucket elevators for fertilizer are used to transport fertilizer raw materials or finished products from lower to higher levels, or for transfer and feeding between different equipment. They use a chain to drive buckets to vertically lift fertilizer, transporting raw materials into storage, transferring them within fertilizer production lines, and loading finished fertilizer products onto trucks. The lifting height ranges from 5-50 meters, with a lifting capacity of 10-100 tons per hour. They are available in carbon steel and stainless steel.

Chain bucket elevators for fertilizer can be used to lift various types of fertilizers, including powders, granules, and small blocks. However, the type of bucket and material required varies depending on the properties of the fertilizer being transported. Deep buckets are used for conveying granular fertilizers to prevent spillage; shallow buckets are used for conveying powdered fertilizers to prevent residue buildup during unloading, and a guide chute helps prevent dust. For fertilizers that are hygroscopic and prone to clumping, buckets with an anti-stick coating are used. For conveying corrosive fertilizers, stainless steel casings are required, and the material strips must be treated with anti-corrosion coatings.

What types of chain bucket elevators for fertilizer are available?

There are two main types of chain bucket elevators for fertilizer: single-chain and double-chain. They differ in lifting height, lifting capacity, and the type of fertilizer they can transport.

Single-chain chain bucket elevator for fertilizer: This type uses a single chain to pull the bucket. It is lightweight and generally used in small to medium-scale fertilizer production. The lifting height is no more than 20 meters, and the lifting capacity is 10-50 m³/h. It is commonly used for lifting fertilizers with uniform granules and no caking.

Double-chain chain bucket elevator for fertilizer: This type uses two parallel chains to drive the bucket, which is installed between the two chains. Its structure is more stable and robust than the single-chain type, with a stronger load-bearing capacity. The lifting height can reach 50 meters, and the lifting capacity is 50-150 m³/h. It can transport large lumps, easily caking, or high-density fertilizers and is suitable for large-scale fertilizer production lines.

What are the advantages of a chain bucket elevator for fertilizer?

The chain bucket elevator for fertilizer uses a vertical conveying method, occupying a small area and making it suitable for spaces with limited space. For fertilizers that are hygroscopic, prone to caking, or slightly corrosive, the hoppers can be made of corrosion-resistant stainless steel with a smooth inner wall to prevent clumping and adhesion. The fully enclosed casing effectively prevents fertilizer from getting damp or dust from spilling, especially in humid southern regions, reducing conveying blockages caused by fertilizer clumping. Furthermore, various hopper types are available, including deep, shallow, and pointed hoppers, and hopper sizes, motor power, and materials can be customized to meet specific needs. For locations with varying conveying environments, a machine equipped with casters at the bottom can be selected for flexible movement and no site restrictions.

How does the chain bucket elevator for fertilizer work?

When the chain bucket elevator for fertilizer is in operation, fertilizer material is evenly fed to the inlet of the elevator by a feeder. The material falls naturally into the hopper. Once the hopper is full, the motor drives the top drive sprocket to rotate. The sprocket pulls the hopper upwards along the track inside the machine casing via a chain. During this process, due to the constraints of the track and the traction of the chain, the hopper maintains an upward-facing opening, preventing material spillage. When the hopper reaches the top of the elevator, the opening changes from upward to downward under the force of gravity, and the fertilizer inside is discharged to the top outlet by gravity and inertia. The fertilizer is then transported through pipes to a designated silo, production line, or other equipment. The empty hopper returns to the bottom from the other side to continue operation.

Chain bucket elevator for fertilizer parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Hopper form | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Conveying volume m/h | Ordinary type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved version | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper | Hopper width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Dou Rong L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Ordinary type | 500 | 512 | 688 | ||||||||||||||

| Improved version | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter × pitch) mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Ordinary type | 9 | 7 | 7 | ||||||||||||||

| Improved version | - | 5 | 5 | |||||||||||||||

| Hopper running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Material*large piece size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

What are the applications of the chain bucket elevator for fertilizer?

Chain bucket elevators for fertilizer are used in fertilizer production, storage, and loading/unloading processes to handle raw material receiving, inter-process material transfer, finished product warehousing, and port operations. They can transport various types of fertilizers, including granular, powdered, and small lump fertilizers, such as urea granules, compound fertilizer granules, monoammonium phosphate, diammonium phosphate powder, potash powder, potassium chloride, potassium sulfate, calcium phosphate, and superphosphate.

What is the role of a chain bucket elevator for fertilizer in fertilizer production?

In fertilizer production lines, chain bucket elevators are primarily used to vertically transport granular or powdered raw materials or semi-finished products such as urea and compound fertilizer from low-lying areas like silos and crusher outlets to higher-lying equipment such as mixers, granulators, screening machines, or finished product silos. This solves the problem of spillage and loss during fertilizer material transport, ensuring continuous operation of the production line. It can be used in conjunction with various equipment in fertilizer production lines. At the front end, it can connect to crushers, pulverizers, and raw material silos; in the middle, it can connect to mixers and granulators; and at the rear, it can connect to screening machines, quantitative packaging machines, belt conveyors, etc., forming a complete material conveying chain for fertilizer production.

Chain bucket elevator for fertilizer solution

A small organic fertilizer processing plant in Pakistan needed to lift fermented organic fertilizer raw materials with a moisture content of about 30% and slight caking from the ground stockpile to the feed inlet of a 3-meter-high granulator, with a conveying capacity of about 1.5 tons per hour. They chose a TH160 Chain Bucket Elevator for Fertilizer, with trapezoidal buckets to prevent caking and material jamming, and a sealed casing to prevent odors and dust. The customer has been using it for more than a year with almost no jamming problems, a very low breakage rate of organic fertilizer, and good sealing. The odor in the workshop is much less than when they used a screw conveyor, and the conveying capacity is stable at about 1.6 tons per hour.

Recommend Product

- Chain Bucket Elevator

- TH Chain Bucket Elevator

- NE Plate Chain Bucket Elevator

- TH type chain bucket elevator