Chain bucket elevator for cement

Thursday December-11 2025 16:44:13

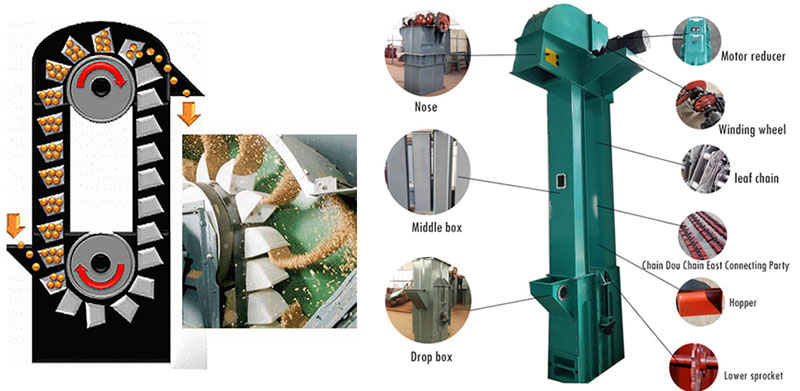

Chain bucket elevators for cement are used in the cement industry to vertically lift abrasive, slightly corrosive powdery, granular, or lumpy cement raw materials, raw meal, and clinker. They utilize a chain to drive buckets, vertically lifting cement from one location to another, with lifting heights ranging from 3 to 50 meters. They can be used for lifting and transferring materials between different stages of a cement production line, with a lifting capacity ranging from 5 m³ to 500 m³ per hour.

The conveying process of the chain bucket elevator for cement occurs within a sealed casing, reducing cement waste. The machine configuration varies depending on the type of cement being conveyed. For conveying abrasive cement clinker, a heavy-duty plate chain type with manganese steel buckets is selected for its wear resistance and durability. For conveying free-flowing powdery cement, ZH-type shallow buckets are used for fast unloading and no residue. For conveying dry, granular, loose cement, SH-type deep buckets are used.

What types of Chain bucket elevators for cement are there?

The type of chain bucket elevator used for cement varies depending on the properties of the cement material being lifted. There are two main types: plate chain and ring chain.

Plate chain bucket elevators for cement use a plate chain as the traction component. The chain links drive the buckets to scoop up cement and rise vertically along the barrel. Plate chains have high load-bearing capacity, are wear-resistant, operate stably, and have a low failure rate. They can be used for lifting abrasive cements such as ordinary Portland cement and slag cement. The lifting height can reach 80 meters, and the hourly lifting capacity of a single unit is typically 50-200 tons, making them suitable for medium- to high-volume cement production scenarios.

Ring chain bucket elevators for cement achieve cement lifting and unloading through a fixed connection between a ring chain and the bucket. Ring chains are flexible, have low starting impact, and are relatively inexpensive, but their wear resistance is lower than that of plate chains. They are more suitable for cement powder with uniform particle size or low abrasive cement clinker. The lifting height is generally 5-50 meters, and the lifting capacity is 30-150 tons/hour. They can be used for small and medium-sized cement storage or short-distance transportation.

What are the functions of a chain bucket elevator for cement?

A chain bucket elevator for cement can be used to continuously lift cement from a low position to a high position, either vertically or at a large angle. In the cement industry production process, chain bucket elevators are used for lifting and transferring raw materials, raw meal, clinker, and finished cement.

Raw material lifting: Lifting crushed limestone, clay, coal, and other raw materials to the raw meal mill or pre-homogenization stockpile.

Raw meal/clinker lifting: Lifting and transferring raw meal before it enters the kiln and clinker after it exits the kiln at multiple process points.

Finished cement product lifting: Lifting the ground cement product from the cement mill to the top of the cement storage silo.

Silo top/bottom conveying: Lifting operations between cement silo groups or at loading and unloading points.

What are the advantages of a chain bucket elevator for cement?

How does the chain bucket elevator for cement work?

After the chain bucket elevator for cement starts, cement is scooped up by the hopper from the bottom inlet. Driven by the chain, the cement-filled hopper is vertically lifted upwards along the inner wall of the machine casing until it reaches the top outlet. Under the influence of gravity and centrifugal force, the hopper tilts, and the cement is automatically discharged from the outlet to enter the next process. The empty hopper is then lowered to the bottom from the other side for continued loading and conveying. The conveying process uses a fully sealed structure to minimize dust leakage.

Chain bucket elevator for cement parameters

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

What are the applications of the chain bucket elevator for cement?

Chain bucket elevators for cement are used in the cement industry for vertical conveying of powdery, granular, and small-lump cement materials. They can lift bulk cement, cement raw meal, clinker, slag powder, fly ash, and similar bulk materials from a low level to a high level. They can be used in cement production lines for lifting and connecting different processing stages, including raw material pretreatment, raw meal feeding into the kiln, clinker cooling and conveying, finished cement warehousing, and packaging systems.

Chain bucket elevator for cement solutions

Chain bucket elevators in the cement industry are used for vertical conveying of bulk materials such as from raw material silos to preheaters and from clinker silos to mills. They can lift powdery raw meal, finished cement, clinker granules, and fly ash. Using the NE series chain bucket elevator for cement, the lifting height can reach 40 meters, and the lifting capacity ranges from 15-200 m³/h. Based on the characteristics of the materials, shallow hoppers are selected for powdery materials to reduce residue, while deep hoppers are selected for granular clinker to improve loading rate. The main contact parts of the elevator are made of wear-resistant manganese steel hoppers and high-strength alloy steel chains, and the shell is made of ordinary steel with wear-resistant inner lining to ensure stable operation under high temperature and high abrasion conditions. It has good sealing performance, stable operation and long service life, and can effectively meet the continuous and efficient conveying needs of cement production lines.

Recommend Product

- Chain Bucket Elevator

- TH Chain Bucket Elevator

- NE Plate Chain Bucket Elevator

- Cement Conveying Bucket Elevator