Cement Conveying Bucket Elevator

A device used for vertical conveying of various bulk materials such as cement raw materials, clinker, and semi-finished products; price range: $450.00 - $6,000.00/set

Lifting capacity: 15-800 cubic meters per hour

Lifting height: 40 meters

Material temperature: below 250℃

It can be used to vertically lift cement powder, cement clinker, ore, limestone, coal powder and other powdery, blocky and bulk materials.

What is Cement Conveying Bucket Elevator?

Cement Conveying Bucket Elevator is a bucket elevator used in the cement industry for vertically lifting cement and similar materials. Using a hopper attached to a chain or belt, it lifts powdered and granular cement materials (such as raw materials, clinker, or fly ash) from low to high locations, reaching heights of up to 60 meters and capable of lifting 5-400 m³ per hour. It is commonly used for elevated cement storage or vertical transport within cement production lines.

Cement conveying bucket elevators are available with shallow (Q-type), curved-bottom (H-type), medium-deep (ZD-type), or deep (SD-type) hoppers to meet the loading and unloading requirements of different cement types. The equipment offers excellent sealing, reduces dust pollution, operates stably, and has a trouble-free time of over 20,000 hours, making it an ideal low-energy conveying solution for the cement industry.

What are the types of Cement Conveying Bucket Elevator?

In the cement conveying industry, depending on the properties of the cement being conveyed, there are four common types of cement conveying bucket elevators: TD belt, TH chain, NE plate chain, and Z type:

| Type | TD belt bucket elevator | TH chain bucket elevator | NE plate chain bucket elevator | Z type bucket elevator (rotating bucket type) |

| Traction component | Tape (temperature resistant 60°C, steel rope tape can reach 80°C) | Forged chain (high temperature resistant 250°C) | Plate chain (wear-resistant and impact-resistant) | Used for "horizontal-vertical-horizontal" transportation, such as cement packaging lines; the transportation capacity can reach 100m³/h, and the lifting height is ≤30m |

| Applicable materials | Powdered and small granular cement, bulk density <1.5t/m³, low abrasiveness. | Cement clinker, slag, etc. with high abrasiveness | Powdered, granular cement and raw materials with moderate abrasiveness | |

| Features | Centrifugal or mixed unloading, low noise; conveying capacity up to 500m³/h, lifting height ≤40m; suitable for conveying raw materials and finished cement in cement plants. | Gravity or mixed unloading, conveying capacity up to 365m³/h, lifting height ≤50m; suitable for high-temperature materials with large specific gravity (such as rotary kiln clinker). | Gravity unloading, large conveying capacity (15~800m³/h); lifting height up to 50m, suitable for large cement production lines. |

In the cement transportation process, TD type (belt type) is selected for powdered cement (such as raw materials and finished cement); TH type (chain type) is selected for high-temperature clinker and slag; NE type (plate chain type) is used for large-capacity cement plants; Z type (rotating bucket type) can be selected for special layout requirements.

What industries can Cement Conveying Bucket Elevator be used in?

Cement conveying bucket elevator is used for vertical transportation of materials in multiple key links of cement production in the cement industry. Their primary applications include:

Raw material conveying: Lifting ground raw meal to a raw meal homogenization silo or directly into a preheater system.

Clinker conveying: After calcining, high-temperature clinker is conveyed to a cooler or storage silo.

Finished cement conveying: Lifting ground cement to a cement silo or packaging system.

Slag/admixture conveying: Lifting auxiliary materials such as slag and fly ash for cement mix preparation.

What are the advantages of Cement Conveying Bucket Elevator?

Cement conveying bucket elevators are designed specifically for vertical conveying of cement and other materials. They occupy a small footprint, making them ideal for transporting bulk cement in cement plants with limited space. They can transport cement from one level to another, with lifting heights ranging from 3 to 60 meters and a lifting capacity of 5 to 800 cubic meters per hour. They offer a wide range of applications, with some models featuring a high-temperature resistant design (capable of withstanding clinker temperatures of 400°C), making them suitable for a variety of materials including raw materials, clinker, finished cement products, and slag. The entire conveying process is fully enclosed to reduce dust spillage.

How does Cement Conveying Bucket Elevator work?

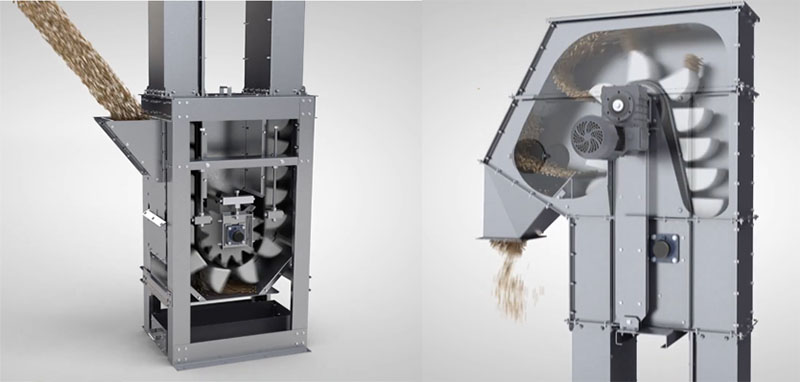

The workflow of a cement conveying bucket elevator consists of four steps: loading, lifting, unloading, and circulation. Cement enters from the bottom feed port, and the hopper continuously moves to scoop up the cement and load it into the bucket. The bucket rises vertically or obliquely along the elevator track as the chain or belt moves. When the bucket reaches the top, the cement is discharged from the bucket into the discharge port by gravity or centrifugal force. The empty bucket continues to move downward and returns to the bottom for the next loading, forming a continuous working cycle.

Cement Conveying Bucket Elevator Parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

What are the structural components of Cement Conveying Bucket Elevator?

The cement conveying bucket elevator primarily consists of core components such as the drive unit, traction member, hopper, casing, and tensioning device. The drive unit (including motor, reducer, and coupling) provides power, driving the traction member (belt, chain, or plate chain) in a circular motion. The hopper (shallow, deep, or combination) is evenly fixed to the traction member, responsible for holding and lifting the cement material. The casing (head, intermediate section, and tail) is fully enclosed to prevent dust from escaping and protect internal components. The tensioning device (screw or weight type) automatically adjusts the tension of the traction member to ensure smooth operation. Furthermore, auxiliary structures such as the inlet and outlet ports, backstop, and inspection door further optimize the equipment's sealing, safety, and maintenance ease, making it an efficient and reliable vertical conveying device for the cement industry.

Cement conveying bucket elevator customer case

| Customer Cases | A cement plant in the Philippines - TGD bucket elevator | A building materials plant in Pakistan - stainless steel bucket elevator | Sinoma Tianshan Cement - New anti-accumulation bucket elevator |

| Application scenarios | Used in large cement production lines to vertically transport cement clinker and finished cement. | Used in vertical transportation of powdered materials (such as raw cement) in cement plants. | Cement production lines can solve the problem of material accumulation in traditional elevators and improve transportation efficiency. |

| Lifting capacity | 30 tons/hour | 6 cubic meters/hour | 15 cubic meters/hour |

| Lifting height | 45m | 2.8 meters | 15m |

How to select a cement conveying bucket elevator?

Selecting the right bucket elevator for cement conveying requires careful consideration of cement properties, lifting height, capacity, power system, and other factors. Below is a detailed analysis for optimal selection.

Cement Characteristics (Material Properties): Cement is a powdery material with a loose density of about 1.2-1.5t/m³. It has low abrasiveness but is prone to dust.

| Parameter | Impact on Selection | Recommended Elevator Type |

| Powder (e.g., Portland cement) | Low abrasiveness, easy to convey | TD/D-type (belt-driven) |

| Granular (e.g., clinker, slag) | High abrasiveness, heavy | TH/HL-type (chain-driven) |

| Moisture content | Risk of clogging, sticking | NE-type (sealed design, anti-clogging) |

| Temperature | Hot clinker (>150°C) | High-temp chain (TH-type, heat-resistant) |

| Explosive dust risk | Need for explosion-proof motors | ATEX-certified models |

Lifting height and capacity: Cement conveying bucket elevators have lifting heights ranging from 3 to 60 meters and conveying capacities ranging from 5 to 800 cubic meters per hour. For lifting heights less than 20 meters, choose the TD belt elevator. For lifting heights between 20 and 40 meters, choose the NE (chain) elevator. For horizontal and vertical conveying, choose the Z elevator.

Drive device: For low power (3-15kW), choose TD type with belt drive, energy saving and low noise; for medium and high power (15-30kW), choose TH/NE type with hardened gear reducer, impact resistant, suitable for heavy load conditions

| Criteria | TD/D-type (Belt) | NE-type (Chain) | TH/HL-type (Heavy Chain) |

| Best for | Powder cement | General-purpose | Hot/clinker/slag |

| Max Height | ≤40m | ≤50m | ≤60m |

| Capacity | Up to 500 m³/h | Up to 800 m³/h | Up to 400 m³/h |

| Temp Limit | ≤80°C | ≤120°C | ≤250°C |

| Maintenance | Low | Medium | High |