Bucket elevator for Rice Mill

Monday October-27 2025 15:56:17

The Rice Mill Bucket Elevator is a vertical conveying system for rice-like materials such as paddy rice, brown rice, finished rice, and rice bran during rice milling. Driven by wear-resistant chains or food-grade rubber belts, it features an anti-breakage hopper to minimize grain damage during the milling process. It can be used for raw grain cleaning, rice hulling, rice milling, color sorting, and packaging, lifting rice from a low location to a fixed height or transferring it between different equipment. The system has a lifting height range of 5-50 meters and a lifting capacity of 2-100 tons per hour. Depending on the type of rice being lifted, a deep hopper can be used to prevent rice from falling when lifting paddy or brown rice, a shallow hopper can be used to reduce breakage when lifting white rice, and a dense hopper can be used to prevent leakage when lifting bran. Materials typically used are stainless steel or food-grade plastic to meet food hygiene standards. Multiple layouts are supported, including C-type, Z-type, and vertical, to accommodate space-constrained factory environments.

Bucket Elevator for Rice Mill Video

What bucket elevators can be used in rice mills?

When choosing a bucket elevator, rice mills need to consider rice type, conveying height, output requirements and anti-crushing requirements. Bucket elevator for Rice Mill is available in C-type, Z-type and vertical types. When choosing a bucket elevator, rice mills need to consider rice type, conveying height, lifting volume requirements and anti-crushing requirements.

C-type Bucket elevator for Rice Mill: adopts the same side for feeding and discharging, suitable for space-constrained scenarios, with a conveying capacity of 1-25m³/h, a lifting height of 2-25m, and low-damage conveying of paddy, brown rice and finished rice.

Z-type Bucket elevator for Rice Mill: It can feed or discharge at multiple points to meet the needs of rice transfer between different levels or different workstations. It is suitable for color sorter return and packaging lines. The length of the upper and lower horizontal sections can be customized, the conveying height can reach 30 meters, and the conveying capacity can reach 50 tons.

Vertical Bucket elevator for Rice Mill: The chain or belt drives the hopper to move the rice vertically, with a maximum lifting height of 60m and a conveying capacity of 800m³/h. It is suitable for efficient transportation of raw grain from large rice mills to rice mills. It is sealed and dustproof, and has stable operation.

What are the applications of Bucket elevator for Rice Mill?

The Rice Mill Bucket Elevator can be used to transport rice vertically or at an angle throughout the entire rice milling process, from raw grain receipt, intermediate processing, finished product storage, to by-product handling, transporting rice from one location to another. At the raw grain stage, rice can be transported from the unloading pit to cleaning equipment like vibrating screens and stoners, addressing the height difference between the rice ground and processing equipment. During intermediate processing, it connects to equipment like hullers, rice mills, and grading screens to transfer pre-processed brown rice and semi-polished rice, preventing material accumulation and ensuring continuous production line operation. At the finished product stage, it can transport finely processed white rice to the finished product bin or packaging machine feed, while also collecting broken rice generated during the grading process and transferring it to the broken rice bin. The elevator can also be used to lift fresh and aged rice as raw material; brown rice (with bran) and semi-hulled brown rice as primary processing; premium, first-grade, and second-grade white rice (classified by grain size) as fine processing; and whole broken rice, fine broken rice, and rice bran (including fine flour) as by-products.

What are the advantages of Bucket Elevator for Rice Mill?

The Bucket Elevator for Rice Mill can transport rice vertically, occupying a small area and suited to the compact production layout of rice mills. It can continuously and stably transport materials such as paddy rice, brown rice, rice, and rice grains. It can reach a height of 50 meters and a lifting capacity of up to 100 tons/hour, achieving high output. The hopper gently transports rice, reducing rice damage and breakage, and ensuring the integrity of rice grains. The sealed conveying method effectively prevents material scattering and leakage during transportation, ensuring product quality and reducing waste. In addition, it supports customized shape support, hopper capacity, configuration and other parameters to meet different types of rice transportation needs.

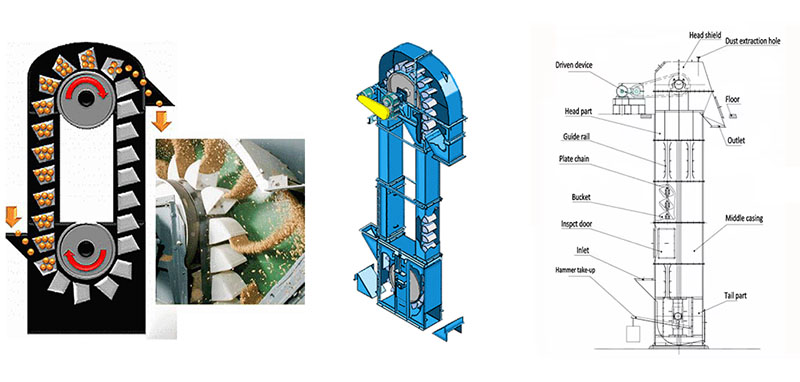

How does Bucket Elevator for Rice Mill work?

The rice bucket elevator transports rice through a hopper uniformly mounted on a belt or chain. Rice enters the machine's housing through a feed inlet at the bottom, where the hopper scoops up the rice. A traction mechanism then drives the hopper vertically upward along the inner wall of the housing, sealing the housing to prevent rice spillage and dust from escaping. When the hopper reaches the top, a roller tilts the hopper, driven by a combination of centrifugal force and gravity, unloading the rice into a discharge port at the top for transport to subsequent processing. The empty hopper then returns to the bottom of the housing through the other side, entering the next round of retrieval and lifting, achieving continuous vertical conveying of rice.

Bucket Elevator for Rice Mill Specifications

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

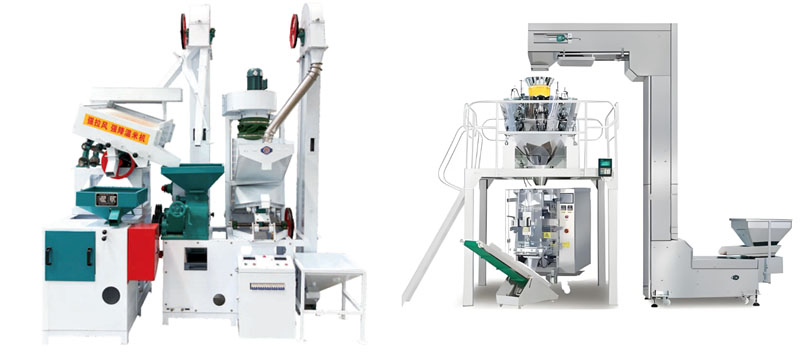

What equipment can the Rice Mill Bucket Elevator be used with?

The Rice Mill Bucket Elevator is designed for use with vibrating screens, rice hullers, rice mills, and finished product silos. When used with a vibrating screen, it vertically conveys raw grain to the screen, helping to remove impurities such as straw and sand, preventing these impurities from affecting the accuracy of subsequent equipment and the quality of the finished rice. When used with a rice huller, it conveys cleaned raw grain to the huller, ensuring continuous feeding and efficient husking. When used with a rice mill, it conveys brown rice to the mill, ensuring continuous operation to remove bran and process it into polished rice. When used with a finished product silo, it conveys polished rice to the silo for storage, facilitating subsequent packaging and turnover, thereby improving overall production efficiency.

Bucket Elevator for Rice Mill Customer Case

| Case Name | Application Scenario | Material Lifting | Lifting Height | Lifting Volume |

| Chinese Pharmaceutical Rice Flour Production Line Project | Rice Flour Milling and Finished Product Transportation to Finished Product Warehouse | Rice Flour | 10m | 9.375t/h |

| European Rice Mill Project | Raw grain is transported to prefabricated steel silos after receipt | Rice | 7.5m | 1000kg/h |

| Rice Milling Project at a Southeast Asian Agricultural Cooperative | Graded white rice is transported to a temporary storage hopper on a packaging scale | Finished white rice | 5.5m | 1.25t/h |

Bucket Elevator for Rice Mill Manufacturer

Dahan Bucket Elevator for Rice Mill Manufacturer manufactures equipment for rice mills, including belt bucket elevators, plate chain bucket elevators, ring chain bucket elevators, Z-type bucket elevators, C-type bucket elevators, and mobile bucket elevators. Available in carbon steel and stainless steel, they offer a full range of models and specifications, sold directly from the manufacturer, with prices ranging from approximately $350 to $7,800. Customized products and added features, such as explosion-proof, high-temperature models, and dust removal systems, are also available based on different rice types or application scenarios.

Recommend Product

- Bucket Elevator for Rice

- Food Grade Bucket Elevator

- Grain Bucket Elevator

- Bucket Elevator for Millet