Bucket Elevators for Bulk Materials Handling

Wednesday October-29 2025 14:43:19

What are bucket elevators for bulk materials handling?

Bucket elevators for bulk materials handling are elevators used for vertical conveying of bulk materials such as powders, granules, and small lumps. Using a hopper attached to a belt or chain, they transport bulk materials from low to high locations, enabling transfer between different heights. They offer lifting heights ranging from 3 to 60 meters and a lifting capacity of 5 to 800 cubic meters per hour, meeting the production needs of various industries. Depending on the particle size, moisture content, corrosiveness, and abrasiveness of the bulk materials being transported, different hopper types are selected. Generally, shallow, deep, and pointed hoppers are available. Shallow hoppers are used for highly fluid powders, deep hoppers are used for dry, loose granules or lumps, and pointed hoppers are more suitable for materials prone to agglomeration and adhesion. Open and closed hoppers are available depending on the application requirements.

Bucket Elevators for Bulk Materials Handling Video

What types of bulk material handling bucket elevators are available?

Bulk material handling bucket elevators mainly come in three types: belt, chain, and Z-type. They differ in their operating principles, the bulk materials they can transport, their lifting height, and the amount they can lift.

Belt-type bucket elevators for bulk material handling use a rubber belt to drive the hopper to lift bulk materials. They offer high speed and are inexpensive, but the belts have limited load capacity and are prone to slippage and deviation when overloaded. They are not suitable for high-temperature or corrosive bulk materials. They are generally used for dry, lightweight bulk materials such as grain, flour, feed, and plastic pellets. They have lifting heights of 5-40 meters and can lift up to 100 m³/h.

Chain-type bucket elevators for bulk material handling use a hopper connected to a chain to convey bulk materials vertically. Chains come in both plate and ring types and are wear-resistant, heat-resistant up to 300°C, and offer strong load-bearing and impact resistance. However, they are also expensive. They are suitable for heavy, abrasive, or high-temperature granular and bulk materials such as cement clinker, coal, and ore. They can reach lifting heights of up to 60 meters and lift up to 800 m³/h.

Z-type bucket elevators for bulk material handling combine horizontal and vertical conveying methods. Their Z-shaped conveying path allows for multiple feeding and unloading points, ensuring excellent sealing, virtually eliminating dust emissions, and minimizing material residue. Suitable for complex structures, they can handle material transfers between different floors and workstations. However, they are limited to a height of 30 meters and are suitable for handling fragile, dust-sensitive bulk materials such as snacks, sugar, milk powder, and chemical powders.

What are the advantages of Bucket Elevators for Bulk Materials Handling?

Bucket Elevators for Bulk Materials Handling utilize a vertical lifting and conveying method, occupying a small footprint and suitable for production sites with limited space but no height restrictions. They can lift bulk materials from the ground to a specified height or into equipment. The lifting process occurs within a sealed enclosure, creating a dust-free environment and preventing material contamination. They offer a large lifting capacity, ranging from 5 to 800 cubic meters, and can handle a wide range of bulk materials, from powders to lumps and abrasives. The overall dimensions, hopper capacity, and speed can be customized based on the material being lifted and the application.

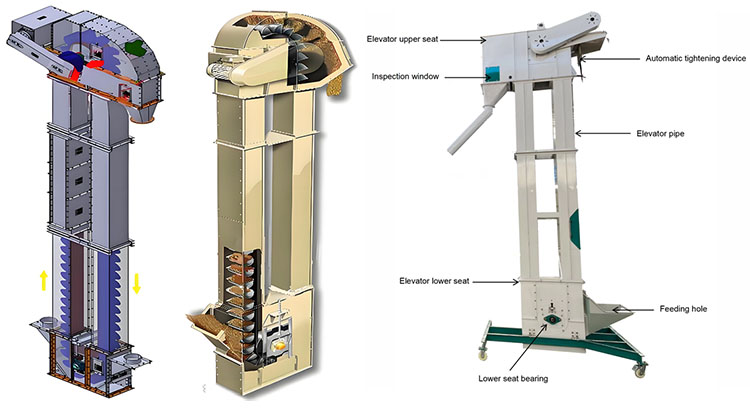

How do Bucket Elevators for Bulk Materials Handling work?

When a Bucket Elevator for Bulk Materials Handling is in operation, a hopper attached to a traction device scoops up bulk material at the bottom inlet. The material is then moved upward to the top of the machine casing by a belt/chain along the inner wall. Under the influence of gravity or centrifugal force, the hopper automatically discharges the material at the outlet. The empty hopper then returns to the bottom of the machine through the other side for reloading and elevation.

Bucket Elevator for Bulk Materials Handling Parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

What are the uses of Bucket Elevators for Bulk Materials Handling?

Bucket Elevators for Bulk Materials Handling are used for vertical conveying of bulk materials in industries such as mining, cement, grain, chemicals, building materials, food, and coal. They enable continuous lifting and feeding of materials between floors. They can handle a variety of bulk materials, including powders, granules, small lumps, and materials with abrasiveness or moisture, such as cement, flour, grain, fertilizer, feed pellets, gravel, coal, limestone, slag, and sand. They meet the diverse lifting requirements, ranging from light and dry to heavy and high-temperature bulk materials.

Bucket Elevators for Bulk Materials Handling Customer Cases

| Application Scenario | Material Lifting | Lifting Height | Lifting Amount |

| A 10,000 t/d Cement Production Line in China | Cement Clinker | 50 meters | 2,000 tons/hour |

| A European grain processing plant | Wheat, corn, and other grains | 48 meters | 300 tons/hour |

| A silo feeding system for a fertilizer plant in India | Urea granules | 35 meters | 315 tons/hour |

| An automated puffed food production line in Pakistan | Puffed grains and nuts | 12 meters | 8 cubic meters/hour |

Bucket Elevators for Bulk Materials Handling Manufacturers

Dahan Machinery is a manufacturer with 15 years of experience in the production and development of bucket elevators for bulk materials handling. We produce a variety of types, including plate chain, ring chain, belt, Z-type, centrifugal, and continuous types. We have a complete range of models and specifications, with prices starting as low as US$450. For conveying different types of bulk materials, we have carbon steel and stainless steel materials to choose from. The hopper capacity ranges from 1L to 8L, and larger ones can be customized according to needs. In addition, for some special materials or application scenarios, we can also make targeted product customization or improvements according to needs, such as explosion-proof types (for flammable and explosive occasions or materials), mobile types that are not restricted by site, and equipped with dust removal devices (suitable for occasions with high dust content and the need to improve the environment and purify the dust).

Recommend Product

- Stainless Steel Bucket Elevator

- NE Plate Chain Bucket Elevator

- Food Grade Bucket Elevator

- Z Type Bucket Conveyor