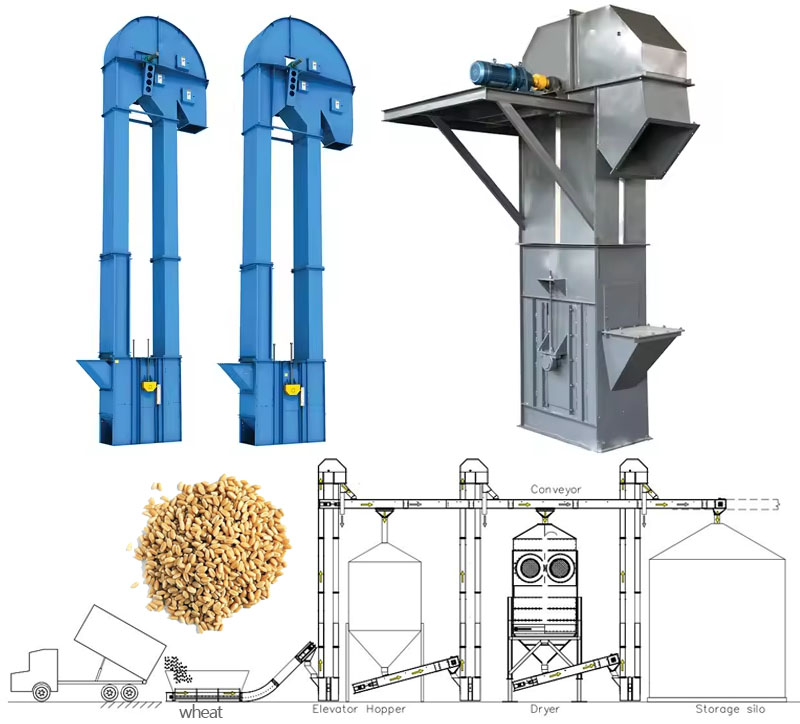

Bucket Elevator for Wheat

Used for vertical transportation of grain crops such as wheat, flour, bran, etc., which can meet the different needs from small flour mills to large grain processing bases

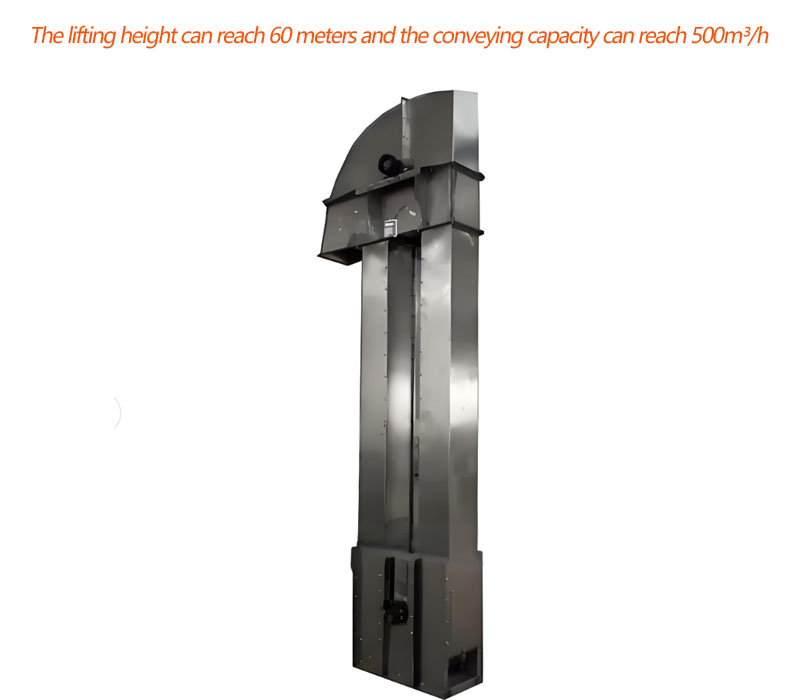

| Lifting height | 3-60 meters (customizable) |

| Transportation capacity | 2-500 tons/hour |

| Power | 0.75-22KW |

| Hopper type | deep hopper, shallow hopper, pointed hopper |

| Hopper material | 304 stainless steel/food grade PP |

What is Bucket Elevator for Wheat?

Bucket Elevator for Wheat is an elevator that can lift wheat from a low place to a specified height; its lifting height ranges from 3 meters to 60 meters, and its lifting capacity can reach 500 cubic meters per hour. It is commonly used in wheat production, processing, and packaging to move wheat from one location to another.

To meet the characteristics of different wheat varieties (such as hard wheat, soft wheat, winter wheat, spring wheat, etc.), Bucket Elevator for Wheat is available in various models, including TH, TD, NE, and Z types. The hopper is available in three specifications: deep hopper (SH type), medium-deep hopper (ZH type), and shallow hopper (Q type), to meet the different needs of small flour mills to large grain depots.

What types of Bucket Elevator for Wheat are there?

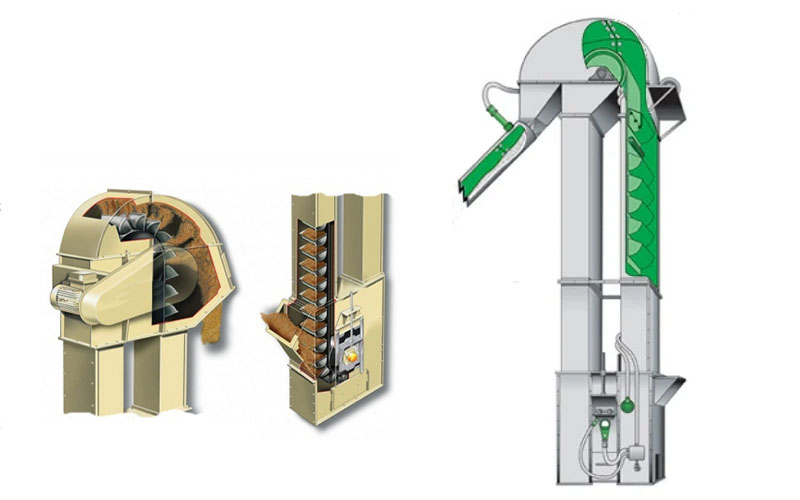

Bucket Elevator for Wheat is available in four specifications: TH ring chain type, TD belt type, NE plate chain type, and Z type. You can choose the appropriate model based on the characteristics of the wheat to be elevated and the application scenario.

TH chain-type Bucket Elevator for Wheat: It adopts forged chain drive, has high mechanical strength, large lifting capacity (nearly double that of HL type), stable operation, and easy maintenance. It is suitable for wheat processing lines with large conveying capacity, large and medium-sized flour mills, grain storage warehouses and other occasions.

TD belt-type Bucket Elevator for Wheat: It uses rubber belt traction, low operating noise, economical cost, simple structure, and is suitable for conveying small particles and good fluidity wheat. It can be used in small flour mills and grain primary processing enterprises.

NE plate chain-type Bucket Elevator for Wheat: It has plate chain drive, high lifting efficiency, and the name directly reflects the conveying capacity (such as NE150=150t/h). It is suitable for high-yield flour production lines and grain deep processing enterprises.

Z-type Bucket Elevator for Wheat: Its multi-stage bending layout allows for flexible adaptation to plant space constraints. It's suitable for vertical or inclined conveying of wheat grains, reducing grain breakage (<0.5%) and ensuring wheat integrity. It boasts a conveying capacity of 5-100 m³/h and a lifting height of 5-30 meters.

What are the advantages of Bucket Elevator for Wheat?

Bucket elevator for wheat has comprehensive advantages such as efficient transportation, low crushing rate, durability, reliability and intelligent maintenance: it adopts intensive hopper and large capacity design (such as TH315 model with a conveying capacity of 35-59m³/h, TH630 up to 114-185m³/h), with unloading structure and buffer system optimized for wheat characteristics, so that the wheat crushing rate is less than 0.5%; the driving power is 30% lower than that of traditional equipment, and the closed structure ensures that dust does not overflow and the noise is less than 75 decibels; the traction chain is forged with carburized and quenched low-alloy steel, with a tensile strength of 190-660KN (depending on the model) and a service life of up to 50,000 hours; it is also equipped with a gravity automatic tensioning device and an overload protection system, which can automatically adjust when stuck, effectively prevent equipment damage and reduce downtime, and significantly improve production efficiency and operation safety.

What is the working principle of Bucket Elevator for Wheat?

When Bucket Elevator for Wheat is working, the bottom hopper scoops up wheat from the feed port, and then driven by a chain or belt, it starts to lift upward. During the rising process, the wheat is loaded in the hopper and will not spill. When the hopper reaches the top, the wheat is discharged from the discharge port under the action of centrifugal force or gravity to complete the transportation. At the same time, the empty hopper continues to circulate downward and returns to the bottom to be reloaded.

Bucket Elevator for Wheat Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

What are the applications of Bucket Elevator for Wheat?

Bucket Elevator for Wheat is suitable for conveying various types of wheat such as hard wheat, soft wheat, high-moisture wheat, germinated wheat, etc., whether it is raw grain, clean wheat grains or wheat after primary processing; it is often used in flour mills, grain storage warehouses, food processing plants, feed mills and other scenes, for wheat in and out of the warehouse, cleaning and screening, and lifting before grinding. Its closed structure can reduce dust spillage and ensure hygiene and safety. At the same time, the low crushing rate design protects the quality of wheat and is suitable for continuous and automated grain processing production lines.

Bucket Elevator for Wheat Customer Cases

A large flour mill project in China: 3 TH315 Bucket Elevators for Wheat are used, with a lifting height of 28 meters, 50 tons of wheat are processed per hour, and they have been running continuously for 2 years without any failures

A grain reserve warehouse project in South Africa: 2 TZD800 double-row bucket elevators are installed, with a lifting height of 45 meters and a conveying capacity of 600t/h, meeting the needs of fast in and out of the warehouse

Wheat flour conveying system of a noodle factory in Shanghai: 5 TD250 belt bucket elevators are used, which run smoothly, with noise less than 65 decibels, and perfectly adapt to the food production environment.

A wheat processing base in Europe: TH500 elevator group is configured, with high temperature resistant design to adapt to dry climate, and no pressure to handle different varieties of wheat.