Bucket Elevator for Sunflower Seeds

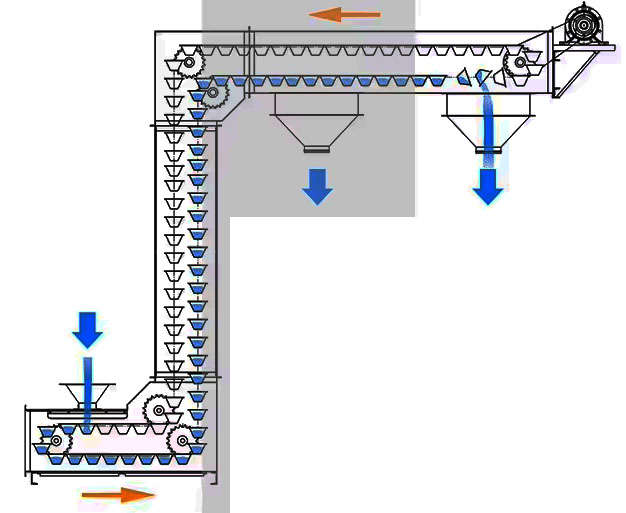

The Z-shaped three-dimensional conveying structure can be used for vertical low-to-high conveying of raw sunflower seeds, fried sunflower seeds, shelled sunflower seeds, etc.

| Lifting height | 3-40 meters (customizable) |

| Transportation capacity | 3-30 tons/hour |

| Power | 0.75-22 kW |

| Hopper | Stainless steel and PP plastic |

| Bucket depth | 1.0L, 1.8L, 2L can be customized |

What is Bucket Elevator for Sunflower Seeds?

Bucket Elevator for Sunflower Seeds can be used to vertically transport shelled or shelled sunflower seeds with a particle size of 5-15mm. It adopts a Z-shaped layout and gently lifts the sunflower seeds from a low place to a high place through the hopper. The conveying process will not cause the sunflower seeds to be broken. The lifting height can reach 40 meters and the lifting capacity can reach 30 tons/hour. The hopper is made of polyethylene or stainless steel, which is wear-resistant and pollution-proof. Its price is as low as US$500 and is suitable for sunflower seed processing, warehousing and other links.

Why choose Bucket Elevator for Sunflower Seeds?

Sunflower seeds need to undergo multiple transfers during the processing process (such as cleaning, shelling, baking, and packaging). Traditional conveying equipment is prone to seed damage, dust leakage, and cross-contamination. Especially for high-value sunflower kernels, the breakage rate directly affects the quality and selling price of the finished product.

Bucket Elevator for Sunflower Seeds can solve these problems well:

Fully sealed design: The closed shell prevents the spillage of sunflower seed dust, which not only meets the food production safety standards, but also reduces material loss, and can reduce 0.3%-0.5% of material waste per shift

Lossless transportation: Compared with traditional transportation methods, Bucket Elevator for Sunflower Seeds adopts inflow feeding and induced unloading design. The breakage rate of sunflower seeds during transportation is less than 0.5%, which is particularly suitable for finishing links with high requirements for material integrity

Flexible layout: Horizontal-vertical-horizontal Z-shaped path, only 1/3 of the floor space of traditional equipment is required, and it can adapt to narrow factory space.

What types of Bucket Elevator for Sunflower Seeds are there?

According to the different requirements of sunflower seed processing technology, Bucket Elevator for Sunflower Seeds can be divided into vertical and Z-type:

Vertical Bucket Elevator for Sunflower Seeds: used in places where space is limited and direct vertical lifting is required. It has a compact structure, small footprint, and a lifting height of up to 9-30 meters. It is suitable for raw sunflower seeds and sunflower seeds with shells after primary cleaning.

Z-type Bucket Elevator for Sunflower Seeds: A process line that requires horizontal-vertical-horizontal composite conveying can achieve multi-directional conveying, with a very low material damage rate. It is suitable for fragile materials such as fried sunflower seeds and seasoned sunflower seeds.

What is the working principle of Bucket Elevator for Sunflower Seeds?

When Bucket Elevator for Sunflower Seeds is working, the sunflower seeds are first evenly fed into the bottom hopper through a vibrating feeder. Then, the hopper fixed on the chain or belt lifts the sunflower seeds up to the designated position, and unloads by gravity and centrifugal force. The empty hopper returns to the bottom from the other end to continue loading.

Bucket Elevator for Sunflower Seeds Technical Parameters

| Parameters | 1.0L model | 1.8L model | 6.5L model |

| Processing capacity | 2~3.5 t/h | 4~6 t/h | 8.5~12 t/h |

| Single bucket capacity | 1.0 liters | 1.8 liters | 6.5 liters |

| Lifting height range | 3~15 meters | 3~20 meters | 5~30 meters |

| Power | 0.75 kW | 1.1 kW | 2.2 kW |

| Hopper material | PP plastic/304 stainless steel optional |

What are the applications of Bucket Elevator for Sunflower Seeds?

Bucket Elevator for Sunflower Seeds is suitable for conveying sunflower seeds with shells, shells, raw seeds, roasted seeds and different particle sizes (5-15mm). It is widely used in edible oil processing plants, food plants (such as melon seed snack production), feed plants and warehousing and logistics. Its closed design is particularly suitable for food-grade production that requires hygiene. It can efficiently complete the conveying tasks of raw material lifting, process transfer and finished product packaging, ensuring that the sunflower seeds are intact and pollution-free.

Conveying solutions for different types of sunflower seeds

| Sunflower seed type | Recommended configuration | Applicable scenarios |

| Sunflower seeds with shells | Carbon steel chain bucket + deep bucket type | Raw materials are initially cleaned and then put into the warehouse for lifting |

| Sunflower kernels | PP plastic hopper + low-speed chain drive | After shelling, the kernels are transported to the packaging line |

| Baked sunflower seeds | Stainless steel body + temperature-resistant chain | High-temperature material transfer after baking |

| Seasoned sunflower seeds | Airtight chassis + anti-corrosion coating | Avoid cross-contamination of spice odors |

Bucket Elevator for Sunflower Seeds Manufacturers