Bucket Elevator for Sugar

Used for continuous vertical lifting of white sugar, brown sugar, rock sugar and other powders, granules, block sugar and loose sugar

| Lifting height | 10-60 meters |

| Conveying capacity | 5-400m³/h |

| Hopper type | SH deep bucket/ZH medium deep bucket/PP plastic bucket/304 stainless steel bucket |

| Motor power | 0.37-22kW |

| Lifting speed | 1.4-2 m/s |

What is Bucket Elevator for Sugar?

Bucket Elevator for Sugar is a bucket elevator that transports sugar materials such as white sugar, brown sugar, crystal sugar, powdered sugar, granules, and blocks from production, processing, and packaging. It realizes the automatic transportation of sugar from low to high places through the continuous operation of the hopper. The lifting height is 5-40 meters and the conveying capacity is 5-400m³/h. It is widely used in sugar factories, food processing, candy production and other industries.

Bucket Elevator for Sugar is made of 304/316L stainless steel, which is corrosion-resistant and easy to clean. Its hopper is available in food-grade PP or stainless steel, which is anti-stick and anti-pollution. Due to the extremely high requirements for sugar hygiene, a fully enclosed structure is used to avoid sugar powder leakage. The Z-type/C-type layout can also be customized to adapt to the production line space.

What types of Bucket Elevator for Sugar are there?

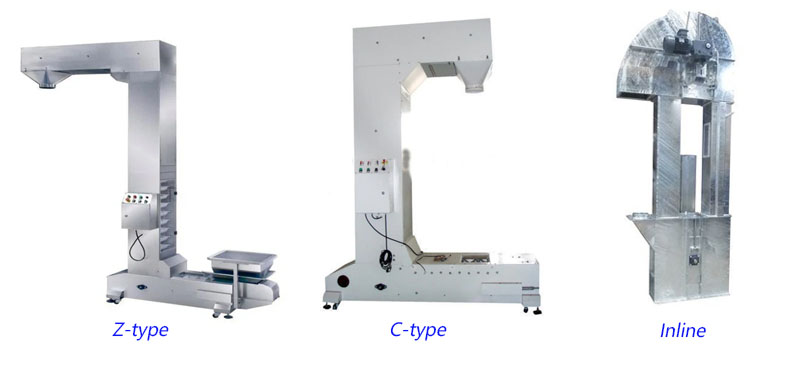

According to the characteristics of different sugar materials, bucket elevators for sugar can be divided into three types: Z-type, C-type and inline type.

Z-type Bucket Elevator for Sugar: suitable for sites with limited space, realizing horizontal-vertical-horizontal transportation, often used for front-end feeding of packaging machines

C-type Bucket Elevator for Sugar: compact design, suitable for medium-height sugar powder lifting

Inline Bucket Elevator for Sugar: traditional vertical transportation, suitable for high-yield and high-height sugar transportation

What are the advantages of Bucket Elevator for Sugar?

Bucket Elevator for Sugar can efficiently transport and elevate various types of sugar vertically. It uses gentle handling methods to prevent sugar from breaking or spoiling. Food-grade materials prevent pollution. The entire sugar production and processing process can be used with confidence. It supports customization and can be adapted to various sugar production lines.

Designed specifically for sugar transportation: Optimized design based on different sugar characteristics (fluidity, humidity, particle size), deep bucket (SH type) is used for white sugar lifting, medium-deep bucket (ZH type) is used for brown sugar and wet sugar, and special anti-stick coating treatment is used to reduce sugar powder residue.

Low crushing rate: shaftless chain transmission reduces friction, and low-speed operation (0.5-1.5m/s) reduces sugar particle breakage.

Large lifting height and conveying capacity: TH type has a maximum lifting height of 50m, and Z type is suitable for medium and short distance lifting of 2-20m, with a conveying capacity of up to 400m³/h, meeting different production needs.

Sealing performance: The fully enclosed structure prevents sugar powder from leaking out and keeps the workshop clean; special sealing strip design, dust leakage rate <0.1%, in line with food-grade hygiene standards.

What is the working principle of Bucket Elevator for Sugar?

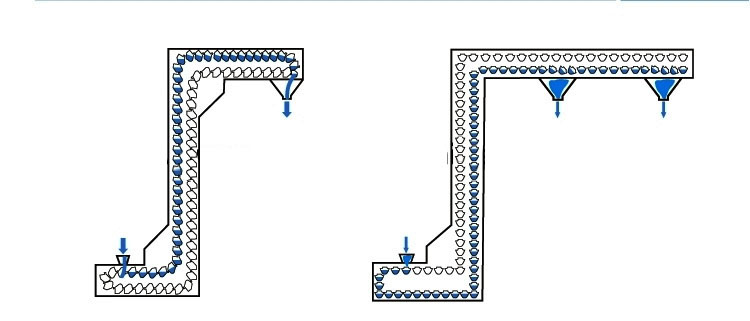

When the Bucket Elevator for Sugar is working, sugar flows into the hopper from the feed port, and the hopper moves upward with the traction chain or belt. When the hopper reaches the top, it bypasses the top drive sprocket or roller, and under the action of gravity and centrifugal force, the sugar is discharged into the discharge port. During the entire conveying process, the hopper continuously scoops up sugar, lifts sugar and discharges it, thereby achieving continuous vertical lifting of sugar. The motor drives the transmission device to keep the traction chain or belt at a stable running speed, ensuring the efficiency and stability of sugar transportation.

Bucket Elevator for Sugar Technical Parameters

| Parameters | TH type chain bucket type | Z type rotating bucket type | Food grade stainless steel type |

| Lifting height | 10-60m | 2-20m | 5-30m |

| Conveying capacity | 10-365m³/h | 0.5-6m³/h | 2-50m³/h |

| Hopper type | SH deep bucket/ZH medium deep bucket | PP plastic bucket | 304 stainless steel bucket |

| Motor power | 0.37-22kW | 0.37-3kW | 0.55-7.5kW |

| Applicable sugars | White sugar, brown sugar | Powdered sugar, rock sugar | Food grade powdered sugar |

Recommended configuration for different sugars:

| Sugar type | White sugar powder | Brown sugar granules | Sugar granules |

| Recommended model | TH-200-S | Z-150-H | C-100-G |

| Hopper type | SH type deep bucket | ZH type medium-deep bucket | ZH type medium-deep bucket |

| Material | 304 stainless steel casing + PP hopper | 304 stainless steel full machine | Carbon steel spraying + PP hopper |

| Typical parameters | Lifting height 20m, conveying capacity 120m³/h | Lifting height 15m, conveying capacity 80m³/h | Lifting height 10m, conveying capacity 50m³/h |

What are the applications of Bucket Elevator for Sugar?

Bucket Elevator for Sugar has a wide range of applications in the transportation of white sugar-related materials, and can meet the refined transportation needs of different industries. In the sugar factory, it can vertically lift raw sugar, white sugar and other raw materials to the storage tank or packaging line, and realize the efficient vertical transfer of materials through the continuously running hopper, providing stable support for the subsequent processing and storage links; in the candy processing scene, for the transportation of raw materials such as chocolate candy and hard candy, the specially designed anti-sticking structure of the bucket elevator can avoid material adhesion and contamination, ensuring that the candy raw materials remain pure during the transportation process, which meets the hygiene requirements of food processing; in the field of food additives, for powdered sugar materials such as glucose and lactose, the bucket elevator adopts a closed conveying method, which can not only prevent dust from escaping, but also ensure the uniform transportation of powdered sugar, meeting the precise batching requirements of additive production; in the pharmaceutical industry, the bucket elevator used for the transportation of pharmaceutical syrup excipients adopts sanitary materials and designs, which strictly complies with the hygiene standards of pharmaceutical production while meeting the efficiency of lifting, and ensures the safety and cleanliness of the transportation process of pharmaceutical excipients. From sugar production to terminal product processing, bucket elevators provide reliable vertical conveying solutions for white sugar-related materials with diverse technical adaptability.

| Application scenario | Lifting height (m) | Lifting volume (t/h) | Motor power (kW) | Equipment model | Main features |

| Lifting white sugar from a sugar factory in Vietnam to the packaging line | 15 | 50 | 11 | TH315 chain bucket elevator | Dust-proof design, anti-crushing of sugar particles, suitable for food-grade conveying |

| Multi-stage lifting of soft and hard candies in a candy factory in China | 8 | 20 | 5.5 | Z-type bucket elevator | Stainless steel hopper, low noise, suitable for fragile candies |

| Lifting sugar powder to mixing tank in a food processing plant in Pakistan | 12 | 30 | 7.5 | NE150 plate chain bucket elevator | Good sealing, prevents sugar powder from flying, meets food safety standards |

How to select Bucket Elevator for Sugar

When selecting Bucket Elevator for Sugar, it is necessary to clarify the physical properties of the sugar to be transported (particle size, humidity, fluidity, etc.), determine the process parameters (lifting height, conveying volume, working temperature, etc.), select the appropriate structure and drive mode, determine the material requirements and special functional requirements, etc.

Select according to the characteristics of sugar: for white sugar powder, choose a deep bucket (SH type), a higher lifting speed (1.2-1.5m/s), and a fully sealed design; for brown sugar granules, choose a medium-deep bucket (ZH type), a medium speed (0.8-1.2m/s), and a stainless steel material; for wet sugar/granules, choose a medium-deep bucket, a low speed (0.5-0.8m/s), and a cleaning system.

Select according to process requirements: Z/C type can be selected for lifting height <10 meters, and inline type is recommended for >10 meters; standard type is selected for conveying capacity <50m³/h, large quantities need to be customized, and food grade stainless steel + PP hopper is selected for hygiene requirements, and carbon steel can be selected for industrial grade.

Select according to production environment: stainless steel material is selected for humid environment, and anti-rust treatment is strengthened; explosion-proof motors and control systems are configured for explosion-proof areas; easy-to-clean design and no dead angle structure are selected for clean workshops.

Food Grade Bucket Elevator

Food Grade Bucket Elevator

Sugar Bucket Elevator

Sugar Bucket Elevator Bucket Elevator for Cocoa Powder

Bucket Elevator for Cocoa Powder