Bucket Elevator for Soybean Meal

A bucket elevator used to vertically lift soybean meal, defatted soybean meal and other soybean meal raw materials to a specified height

| Lifting height | 3-40 meters (customizable) |

| Transportation capacity | 2-200 tons/hour |

| Power | 0.75-3KW |

| Hopper material | 304 stainless steel/food grade PP |

What is Bucket Elevator for Soybean Meal?

Bucket Elevator for Soybean Meal is a vertical conveying device for soybean meal and other powdered and granular materials. It utilizes a hopper-belt structure to vertically elevate soybean meal from a low to high position. Available heights range from 5 to 40 meters, it can transport 10 to 200 tons per hour. It solves the challenge of vertical conveying in soybean meal storage and processing, improving efficiency while reducing material breakage and ensuring meal quality. It is suitable for use in soybean meal feed mills, oil and fat processing plants, and biofuel production lines, encompassing feeding, loading, and process transfer.

Bucket Elevator for Soybean Meal has deep hoppers (for high bulk density soybean meal) and shallow hoppers (for light soybean meal) available. Made of stainless steel or carbon steel, it is corrosion-resistant, wear-resistant, and non-stick, reducing soybean meal residue.

What types of soybean meal can Bucket Elevator for Soybean Meal transport?

Bucket Elevator for Soybean Meal can be used to transport various types of soybean meal, including granular, powdery and highly viscous. The following are equipment models for different types of soybean meal selection.

| Soybean meal type | Characteristics | Recommended model | Key configuration points |

| Full-fat soybean meal | High oil content (7-9%), good fluidity, low viscosity | TD-20 type | Standard bucket spacing (250mm), conventional line speed (1.2m/s) |

| Defatted soybean meal | Low oil content (<1%), poor fluidity, easy to agglomerate | TD-20 enhanced type | Reduce the spacing between the buckets (200mm), reduce the line speed (0.8m/s), and add a vibration cleaning device |

| Expanded soybean meal | Low bulk density, easy to generate dust | TD-05 sealed type | Fully sealed design, increase dust removal interface, use anti-static materials |

| Fermented soybean meal | High humidity (10-12%), easy to adhere | TD-20 anti-stick type | Teflon coating on the surface of the dustpan, with an additional cleaning door, can be quickly disassembled for cleaning |

| High-temperature soybean meal | The temperature can reach 80℃ | TD-20 heat-resistant type | High-temperature resistant dustpan material, with additional heat dissipation device |

Note: We can provide personalized selection solutions based on your specific soybean meal characteristics and process requirements to ensure the best match for the equipment.

What are the advantages of Bucket Elevator for Soybean Meal?

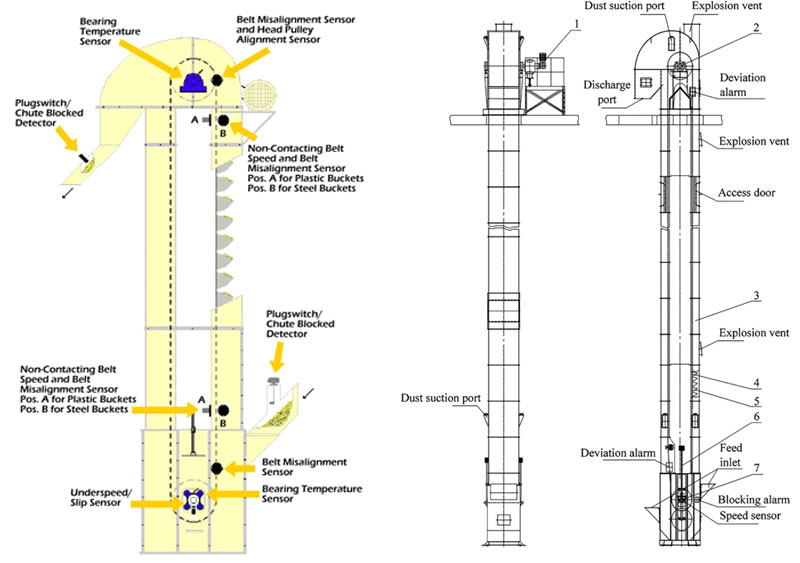

Bucket Elevator for Soybean Meal adopts a sealed structure, which can effectively solve the problems of dust flying, material residue, severe wear and low conveying efficiency during soybean meal transportation. Its configuration is flexible to meet the needs of different working conditions, as follows:

Efficient sealing design: The fully enclosed structure effectively prevents soybean meal dust from overflowing, and the working environment is cleaner, meeting food-grade hygiene standards

Wear-resistant configuration: The ultra-high molecular weight polyethylene bucket is used, and the wear resistance is 3-5 times that of ordinary plastics; high-strength thick flat tape traction, the service life is more than 5 years; wear-resistant lining plates are installed in key parts, which is especially suitable for defatted soybean meal with strong abrasiveness.

Flexible adaptation: The machine base can be equipped with forward and reverse feed hoppers to meet the requirements of different process layouts; the lifting height of 3-40 meters can be customized to meet various plant space requirements.

Low-energy operation: The cycloidal pinwheel reduction motor is directly connected to drive, and the transmission efficiency is as high as 98%; 1.1-1.5kw motor can achieve 15-200 tons/h of conveying capacity, which is 20% energy-saving than similar products.

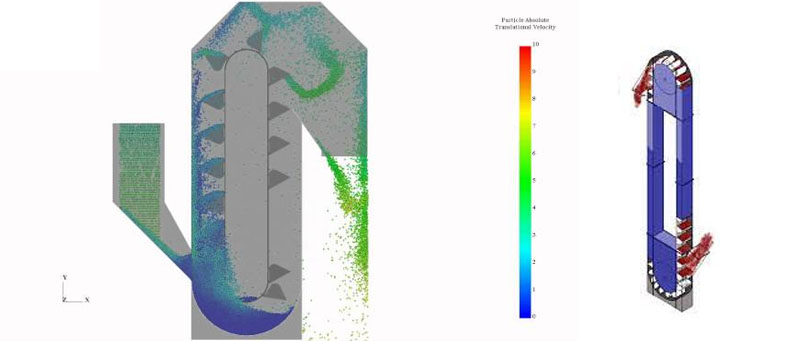

What is the principle of Bucket Elevator for Soybean Meal?

Bucket Elevator for Soybean Meal uses a motor to drive a belt or chain to circulate, driving the hopper fixed on it to dig soybean meal from the bottom. The hopper rises to the top with the transmission device and then flips over, throwing the soybean meal into the discharge port to complete vertical transportation.

Bucket Elevator for Soybean Meal Technical Parameters

| Model | Conveying capacity (m/h) | Power (kW) | Lifting height (m) | Applicable soybean meal type | Overall dimensions (mm) |

| TD-05 | 3-5 | ≥0.75 | 6 | Small batch, multiple soybean meal switching | 860×821×7400 |

| TD-20 | 15-30 | ≥1.1 | 6 | Continuous production of mainstream soybean meal | 1130×1057×7630 |

| TD-30 | 30-50 | ≥2.2 | 6-12 | High output in large feed mills | 1350×1200×customized |

| TD-H40 | 15-20 | ≥3.0 | up to 40 | Special requirements for high-rise factories | Customized on demand |

What are the structures of Bucket Elevator for Soybean Meal?

Bucket Elevator for Soybean Meal mainly consists of a drive device (motor + reducer), transmission parts (belt/chain), hopper (dust bucket), head (upper box), base (lower box), barrel (middle section), tensioning device and inlet/outlet. Among them, the hopper is responsible for digging soybean meal, the transmission parts drive it to circulate and rise, the barrel is closed to prevent dust, and the tensioning device keeps the belt/chain running stably. According to the characteristics of soybean meal, it can be optimized to an anti-stick coating hopper, a high temperature resistant structure or a sealing design to ensure efficient transportation.

Bucket Elevator for Soybean Meal Customer Case

| Industry | Customer needs | Solution | Effect |

| Feed processing industry | The original equipment had serious residue when conveying defatted soybean meal, and it needed to be shut down for cleaning 3-4 times a month | TD-20 anti-stick Bucket Elevator for Soybean Meal, Teflon coating on the bucket surface | No manual cleaning required for 6 months of continuous operation, the residual rate dropped from 3% to 0.2% |

| Soy sauce brewing enterprise | Fermented soybean meal has high humidity, and ordinary equipment is easy to clog, affecting continuous production | Customized TD-30 enhanced Bucket Elevator for Soybean Meal, adding vibration cleaning device and quick maintenance door | Completely solve the clogging problem, and reduce annual maintenance time by 80% |

| Soy protein extraction factory | High temperature soybean meal (80℃) causes ordinary plastic buckets to deform and fail | High temperature resistant TH40 Bucket Elevator for Soybean Meal, using special alloy buckets and heat-resistant tape | Equipment life extended from 6 months to more than 4 years |

| Organic fertilizer production | Soybean meal and other raw materials are transported alternately, and cross contamination is serious | All stainless steel sealed Bucket Elevator for Soybean Meal, equipped with CIP cleaning system | Achieve pollution-free switching of multiple materials to meet organic certification requirements |

| Large-scale grain and oil comprehensive enterprises | Limited plant space requires high-volume lifting equipment | Compact TD-30, lifting height of 25 meters, only 1.5m² | Save 30% of plant space, and the conveying capacity reaches 40m³/h |