Bucket Elevator for Sorghum

Bucket elevator for lifting sorghum from low to high

| Lifting height | 1-60m |

| Conveying capacity | 0.5-100m³/h |

| Power | 3-55KW |

| Sorghum type | Red sorghum, white sorghum, sweet sorghum, brewing sorghum, fodder sorghum, etc. |

| Material | Carbon steel/stainless steel |

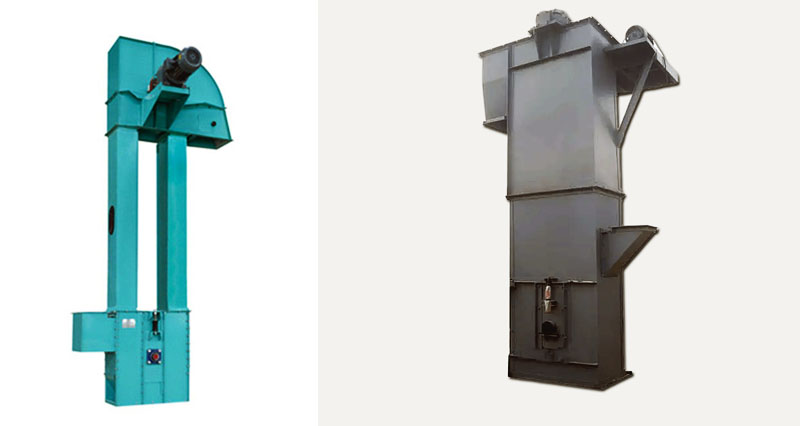

What is Bucket Elevator for Sorghum?

Bucket Elevator for Sorghum is a bucket elevator designed for vertical conveying of grain materials such as sorghum. It uses a continuous circulation method to lift sorghum from a low place to a high place. The lifting height can reach 50 meters to meet the height requirements of different plant buildings.The conveying capacity can reach 100m³/h. A variety of specifications are available to adapt to small-scale to large-scale production. The hopper material is available in stainless steel, carbon steel, engineering plastics, etc., which meet food grade and wear-resistant requirements.

Bucket Elevator for Sorghum optimizes the hopper shape and running speed specifically for the characteristics of sorghum particles. It adopts a low-speed and large-capacity design. Compared with traditional elevators, it can reduce the crushing rate by more than 30%. It is an ideal choice for industries such as breweries, feed mills, and grain storage.

Why choose Bucket Elevator for Sorghum?

As a high-hardness granular material, sorghum faces three major pain points during the lifting process: high particle crushing rate, wet and sticky varieties are easy to block the material, and the lifting volume is unstable. Bucket Elevator for Sorghum solves the problem through three core technologies:

Ultra-low crushing design: With a large-capacity bucket and ultra-low speed structure (≤28r/min), the material is fed by gravity flow to avoid extrusion and extrusion, and the crushing rate is controlled within 0.5%, which is significantly better than the industry level of 3% for ordinary models;

Anti-blocking material optimization: For high-humidity varieties such as glutinous sorghum, the ZH-type deep arc hopper and squirrel cage waterproof wheel are configured to prevent the material from sticking to the wall; for dry bulk varieties such as brewing sorghum, the SH-type deep bucket is used to achieve centrifugal rapid unloading;

High-yield and stable operation guarantee: The conveying capacity is as high as 58m³/h (equivalent to 30 tons/hour), matched with ZLY hard-toothed reducer and backstop, and it can run continuously for 20,000 hours without failure

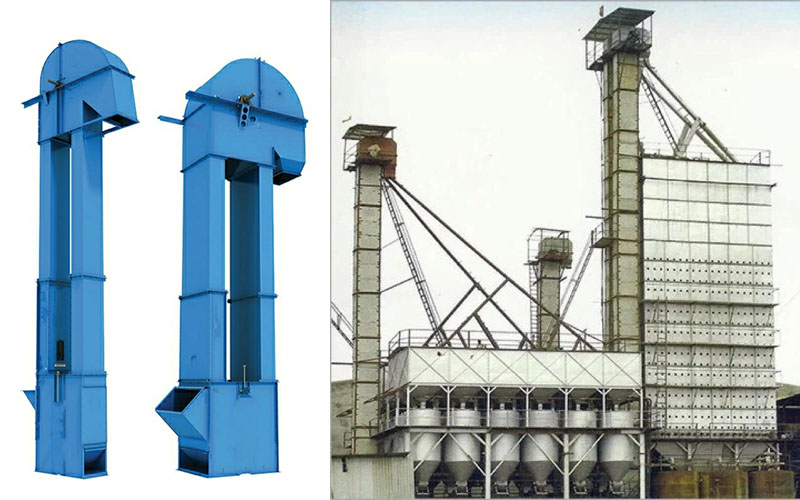

What types of Bucket Elevator for Sorghum are there?

Bucket Elevator for Sorghum can be divided into TH chain type and TD belt type according to the characteristics of sorghum and production needs:

| Model classification | TH chain bucket elevator for Sorghum | TD belt bucket elevator for Sorghum |

| Applicable sorghum type | Highly abrasive materials (such as hulled sorghum) | Dry loose sorghum (such as brewing sorghum) |

| Hopper selection | S-type deep round bottom bucket (anti-sticking) | SD type deep bucket (high-speed unloading) |

| Lifting height range | 10-50 meters | 5-40 meters |

| Maximum lifting capacity | 58m³/h | 45m³/h |

| Typical application scenarios | Sorghum processing plant, feed factory | Grain silo transfer, seed processing line |

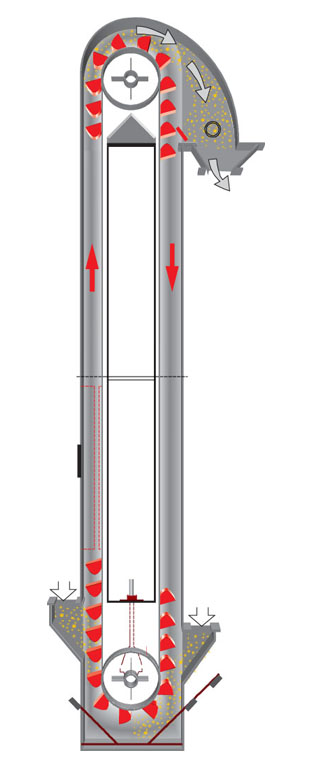

What is the working principle of Bucket Elevator for Sorghum?

After Bucket Elevator for Sorghum is started, sorghum flows evenly into the hopper from the bottom feed port. The hopper filled with sorghum rises vertically with the traction device (chain or belt) and runs in a closed casing to avoid external contamination. After the hopper reaches the top, the sorghum is discharged from the discharge port under the dual action of gravity and centrifugal force, and the empty hopper returns to the bottom along the other side, completing a working cycle.

Parameters of Bucket Elevator for Sorghum

| Model | Hopper type | Conveying capacity (m/h) | Hopper volume (L) | Chain specifications | Lifting height (m) | Motor power (kW) |

| TH160 | ZH medium-deep bucket | 15.77 | 1.2 | Φ14×50mm | ≤50 | 3-7.5 |

| TH160 | SH deep bucket | 24.97 | 1.9 | Φ14×50mm | ≤50 | 4-11 |

| TH200 | ZH Zhongshendou | 17.87 | 1.5 | Φ14×50mm | ≤50 | 4-11 |

| TH200 | SH deep bucket | 28.6 | 2.4 | Φ14×50mm | ≤50 | 5.5-15 |

| TH315 | ZH Zhongshendou | 35 | 3.75 | Φ18×64mm | ≤50 | 7.5-18.5 |

| TH315 | SH deep bucket | 59 | 6.0 | Φ18×64mm | ≤50 | 11-22 |

| TH400 | SH deep bucket | 94 | 9.5 | Φ22×86mm | ≤50 |

15-30 |

What are the applications of Bucket Elevator for Sorghum?

Bucket Elevator for Sorghum Customer Case

| Project name | Equipment model | Quantity | Lifting height/conveyance | Effect description |

| A well-known liquor group project | TH315 chain-type deep bucket elevator | 8 units | 28m/60m³/h | Meet the sorghum transportation needs of 50,000 tons of base wine per year, and the crushing rate is 30% lower than the industry standard |

| Large feed enterprise production line | TD200 belt-type shallow bucket elevator | 5 units | 15m/20m³/h | Achieve non-crushing transportation of feed sorghum, stable equipment operation, and simple maintenance |

| Grain reserve warehouse renovation project | NE50 plate chain elevator | 12 units | 35m/50m³/h | Meet the high-efficiency storage and retrieval requirements of modern granaries, and reduce operating power consumption by 25% |

| Sweet sorghum project of bioenergy company | TH400 ring chain medium-deep bucket elevator | 4 units | 18 meters/90m³/h | Adapt to the high moisture characteristics of sweet sorghum, non-blocking operation |