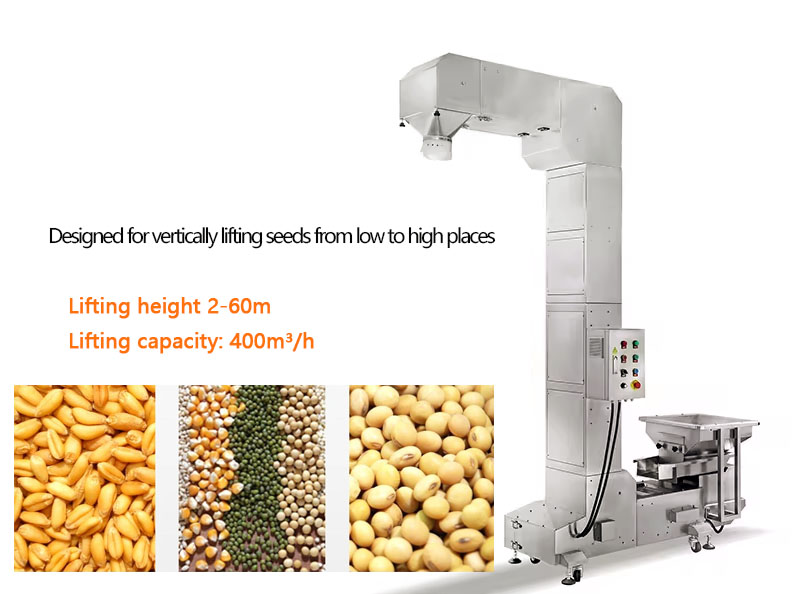

Bucket Elevator for Seeds

It is used to transport seed materials vertically from a low place to a designated high place. The use of a low-speed, large-capacity hopper can prevent the seeds from being damaged or leaked during transportation.

| Lifting height | 2-60m |

| Conveying capacity | 10-400m³/h |

| Drive power | 0.75-7.5KW |

| Hopper type | Deep hopper, shallow hopper, anti-stick hopper, food stainless steel hopper |

What is Bucket Elevator for Seeds?

Bucket Elevator for Seeds is a bucket elevator used for conveying seed materials (such as seeds, grains, fertilizers) vertically or at a large angle in the agriculture, grain processing and seed industries. It adopts a low-speed + large-capacity hopper structure to ensure that seeds are not damaged or leaked during transportation. It can smoothly lift seeds, grains and other materials from a low level to a specified height. The height can meet customized needs of 1 meter to 60 meters, and the conveying capacity ranges from 2 tons/hour to 100m³/h.

Bucket Elevator for Seeds hopper can be made of food-grade PP plastic, stainless steel or carbon steel galvanized material, and the body is also available in carbon steel and stainless steel to ensure hygiene and durability, suitable for seed processing links with high requirements for cleanliness; widely used in grain drying, seed sorting and packaging lines, to achieve gentle transportation, with a breakage rate of less than 0.1%.

How to choose bucket elevator for different seeds?

Bucket Elevator for Seeds can be divided into belt type, double chain type, ring chain type, Z type, etc., which can be used to lift light, fragile, high oil and hybrid seeds. The corresponding model can be selected according to the characteristics of the seeds.

| Seed type | Recommended model | Hopper material | Technical points | Representative crop seeds |

| Small particle light seed | Belt elevator | Food grade PP | Enclosed anti-scattering design | Sesame, rapeseed, tobacco |

| Easily broken brittle seeds | Double-chain low-speed elevator | 304 stainless steel | Buffering feed device | Rice, vegetables, melons |

| High-fat sticky seeds | Plate chain elevator | Mirror stainless steel 316 | Nano coating on the inner wall of the bucket for anti-sticking | Soybeans, sunflowers, peanuts |

| High-priced hybrid seeds | Fully sealed Z-type elevator | Aluminum alloy + Teflon | Nitrogen filling anti-oxidation system | Corn, cotton, hybrid rice |

What are the advantages of Bucket Elevator for Seeds?

Bucket Elevator for Seeds runs at an ultra-low speed of 0.5 - 1.5m/s, which greatly reduces the collision between seeds and strictly controls the breakage rate within 0.1%, fully guaranteeing the quality of seeds. The equipment adopts a fully enclosed structure, like a solid barrier, effectively preventing seed dust from spilling out, fully complying with GMP food hygiene standards, and providing strong guarantees for the cleanliness and safety of the production environment. In terms of high efficiency and energy saving, large-capacity hoppers are densely arranged, and the conveying capacity can reach up to 200m³/h, which saves 30% energy compared to traditional conveying equipment and significantly reduces energy consumption costs. There are various material options, including 304 stainless steel or carbon steel galvanized materials, which can be flexibly selected according to different seed storage environments, with strong corrosion resistance to ensure stable operation of the equipment. Moreover, it uses EPU molecular guides or wear-resistant belts, and the operation process is stable and reliable, with a service life of more than 50,000 hours, reducing the frequency of failures and maintenance.

How does Bucket Elevator for Seeds work?

Bucket Elevator for Seeds completes the conveying process through hopper scooping, vertical lifting and gravity unloading: seeds evenly enter the hopper from the bottom feed port (deep hopper is suitable for dry seeds, shallow hopper is suitable for fragile seeds), the chain/belt drives the hopper to rise vertically, the casing seal prevents dust from overflowing, and the seeds are discharged at the top by centrifugal force or gravity and enter the next processing link.

Bucket Elevator for Seeds Parameters

| Model | Conveying capacity (m³/h) | Lifting height (m) | Applicable seeds | Hopper type | Drive power (kW) |

| TH160 | 5-15 | ≤20m | Wheat, corn | Deep bucket | 1.5-3.0 |

| NE30 | 10-30 | ≤30m | Soybean, rapeseed | Shallow bucket | 2.2-5.5 |

| TD250 | 20-50 | ≤40m | Rice, hybrid seeds | Anti-sticking bucket | 4.0-7.5 |

| Z-type elevator | 1-10 | ≤6m | Small grain seeds | Food grade stainless steel bucket | 0.75-2.2 |

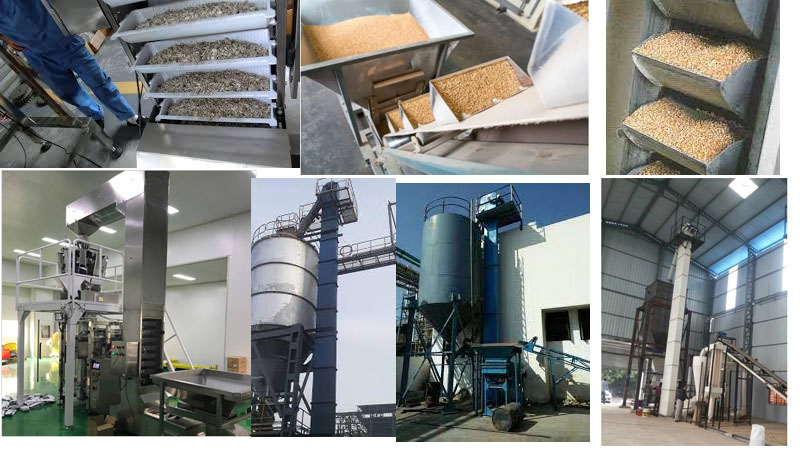

What are the applications of Bucket Elevator for Seeds?

Bucket Elevator for Seeds is widely used in agricultural production and seed processing. In the seed storage process, it can vertically lift various types of crop seeds after harvest, such as corn, wheat, rice and other grain seeds, soybeans, rapeseed, sunflower seeds and other oil seeds, and tomato, cucumber, carrot seeds and other vegetable seeds from transport vehicles or temporary storage sites to the height of the warehouse for storage, optimize the use of storage space, and facilitate classification, storage and management.

Bucket Elevator for Seeds Customer Cases

| Application scenarios | Lifting height | Lifting amount | Motor power | Equipment model/features | Applicable seed type |

| Seed processing plant initial cleaning process | 5m | 3-5t/h | 2.2kW | TH315 chain bucket elevator, galvanized hopper | Corn, wheat and other large seeds |

| Seed coating machine feeding system | 8m | 2-3t/h | 1.5kW | Z-type bucket elevator, 304 stainless steel | All kinds of coated seeds |

| Seed storage and transportation | 15m | 10-15t/h | 7.5kW | TD400 belt bucket elevator, dustproof design | Soybeans, rice, etc. |

| Seed packaging line automatic feeding | 3m | 1-2t/h | 0.75kW | C-type bucket elevator, variable frequency speed control | Small particle vegetable seeds |

How to choose Bucket Elevator for Seeds?

When choosing Bucket Elevator for Seeds, you need to consider seed type, lifting capacity, and environmental hygiene:

Seed type (particle size, fluidity): Determine the hopper shape (deep bucket/shallow bucket).

Transportation capacity requirement: 2-400m³/h, choose a matching model (TH/NE/TD).

Sanitary requirements: Food-grade stainless steel is preferred (such as hybrid seeds, organic seeds).

Bucket Elevator for Rice

Bucket Elevator for Rice