Bucket Elevator for Sand

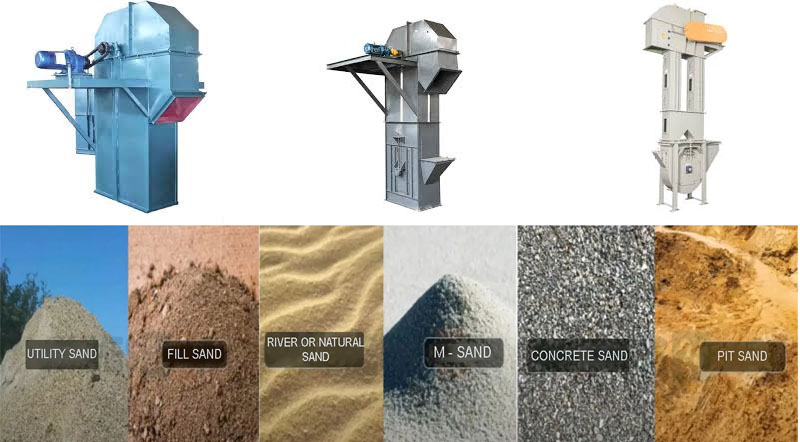

It is a bucket elevator used for conveying granular or small block sand and gravel such as sand, gravel, machine-made sand, river sand, etc. vertically from low to high.

| Lifting height | 3-80 meters, can be customized according to needs |

| Transportation capacity | 4-900 tons/hour |

| Hopper capacity | 5-50 liters |

| Motor power | 5.5-75 kW |

| Operating speed | 0.8-3.5 m/s |

What is Bucket Elevator for Sand?

Bucket Elevator for Sand is a bucket elevator for lifting various sand and gravel materials (including river sand, machine-made sand, quartz sand, limestone, gypsum, etc.); it can smoothly transport sand and gravel from a low place to a height of 80 meters, with a conveying capacity of up to 900 tons per hour. It is the preferred equipment for sand and gravel production lines, quarries and building material processing plants.

Bucket Elevator for Sand is made of carbon steel (Q235), stainless steel (304/316) and wear-resistant steel (NM360/400), which can meet the corrosion resistance, wear resistance and lightweight requirements of different working conditions. Common models include TD series (general purpose, lifting height ≤40m), TH series (chain type, bulk materials), NE series (plate chain type, high efficiency and heavy load) and HL series (old-style chain), etc., which can be selected according to needs.

What types of Bucket Elevator for Sand are there?

Bucket Elevator for Sand is mainly divided into three categories according to the different traction components: plate chain type, ring chain type and belt type, which can adapt to sand and gravel materials of different particle sizes, humidity and temperature.

| Sand type | Applicable models | Hopper type | Features |

| Dry sand/fine sand | TD series (tape type) | Shallow bucket (Q type) | Lightweight design, anti-clogging |

| Wet sand/sticky sand | TH series (ring chain type) | Medium-deep bucket (ZH type) | Anti-adhesion, moisture-resistant |

| Crushed stone/mechanical sand | TH series (heavy chain) | Deep bucket (SH type) | Impact-resistant, strong wear resistance |

| High-temperature sand (such as foundry sand) | TH high-temperature resistant type | Heat-resistant steel bucket | Can withstand high temperatures of 250℃ |

| Large, highly abrasive sand and gravel materials, such as granite crushed stone, limestone, etc. | NE series plate chain type | Using high-strength alloy steel plate chain as traction parts | The maximum conveying capacity can reach 900t/h and the lifting height can reach 40 meters |

Why choose Bucket Elevator for Sand?

Bucket Elevator for Sand adopts high-strength chain or belt traction, combined with intensive hopper layout, to achieve efficient, stable continuous lifting, fully enclosed structure, and reduce dust pollution during sand and gravel transportation.

Large-capacity transportation: The hopper adopts intensive layout, and the single-machine conveying capacity can reach 900t/h, which meets the needs of large-scale sand and gravel production lines

High efficiency and energy saving: inflow feeding + induced unloading, reduce return material, and reduce power consumption by 30%.

Widely applicable: It can convey dry sand, wet sand, gravel, slag, etc., with a density of ≤1.5t/m³.

Wear-resistant design: The hopper is made of manganese steel or polyurethane, which is suitable for highly abrasive sand and gravel, and the chain and bearings are made of alloy steel, with trouble-free operation for more than 20,000 hours.

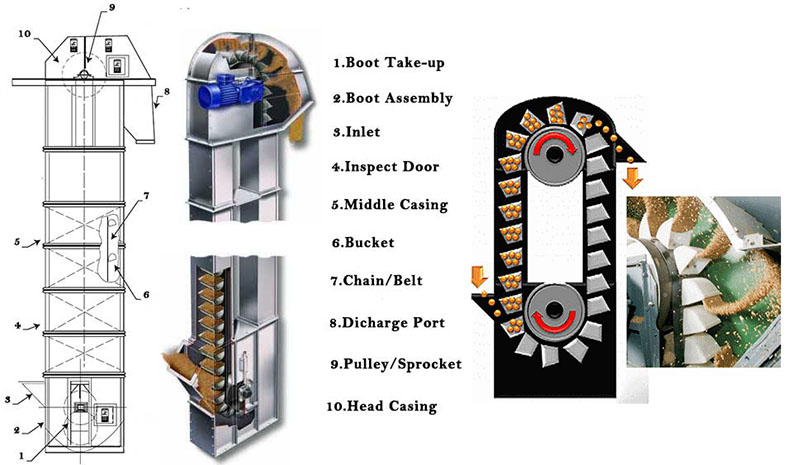

What is the principle of Bucket Elevator for Sand?

Bucket Elevator for Sand scoops the material through the hopper, lifts it vertically to the top by the traction part (belt or chain), and discharges it to the discharge port by centrifugal force or gravity. The process is as follows:

Feeding: Sand flows from the lower storage bin into the hopper.

Lifting: The motor drives the traction mechanism to drive the hopper upward.

Discharging: Sand is thrown into the discharge trough at the top by centrifugal force (high speed) or gravity (low speed)

Bucket Elevator for Sand Parameters

| Model | NE50 | NE200 | NE300 | TH160 | TH250 | TD315 |

| Conveying capacity (t/h) | 22 | 100 | 200 | 35 | 80 | 118 |

| Lift height (m) | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤30 |

| Hopper capacity (L) | 3.2 | 10 | 20 | 5.6 | 14 | 9.5 |

| Chain/belt speed (m/s) | 1.25 | 1.25 | 1.25 | 0.8 | 0.8 | 2.0 |

| Motor power (kW) | 5.5 | 18.5 | 30 | 7.5 | 15 | 11 |

| Applicable sand and gravel type | Small and medium pieces | Large pieces | Extra large pieces | Wet sand | Viscous sand | Fine sand |

Note: For special sand and gravel materials, we can also provide the following customized parameters:

High temperature resistant type: can withstand high temperature sand and gravel materials up to 250℃

Anti-corrosion type: suitable for corrosive sea sand and other materials

Anti-sticking type: special treatment for high-humidity sticky sand and gravel

Large inclination type: adapt to special site installation requirements

What are the applications of Bucket Elevator for Sand?

Bucket Elevator for Sand can be used for vertical lifting of river sand, machine-made sand, quartz sand and other materials in sand and gravel mining and processing; lifting of aggregates, sand and other raw materials in the production of cement and concrete prefabricated parts in the building materials manufacturing industry; transportation of mineral raw materials such as iron ore and limestone in the mining and metallurgy industry; loading and unloading of bulk sand and gravel at ports and terminals, etc.

For different application scenarios, we provide professional Bucket Elevator for Sand solutions:

Explosion-proof type: used in flammable and explosive environments

Food grade: used for lifting food-grade raw materials such as quartz sand

Ultra-quiet type: suitable for urban construction sites

Mobile type: suitable for temporary engineering needs

Bucket Elevator for Sand Customer Cases

| Application scenarios | Lifting height (m) | Lifting volume (t/h) | Motor power (kW) | Equipment model | Main features |

| Vertical conveying of sand and gravel aggregates in a sand and gravel aggregate plant in Southeast Asia | 25 | 120 | 22 | TH315 chain bucket elevator | Wear-resistant chain, dust-proof design, suitable for high-load continuous operation |

| A concrete mixing station in the United States lifts machine-made sand to the storage bin | 18 | 80 | 15 | NE150 plate chain bucket elevator | Good sealing, anti-leakage, low-noise operation |

| Quartz sand grading and lifting in a quartz sand processing plant in China | 30 | 150 | 30 | TD400 Belt bucket elevator | Corrosion-resistant hopper, high stability, suitable for fine materials |