Bucket Elevator for Salt

Vertically lift industrial salt, snow-melting salt, sea salt, coarse salt, chemical salt, high-temperature salt, edible salt, fine salt and other powder, granules, block salt materials from low to high

| Lifting height | 3 meters - 60 meters |

| Conveying capacity | 5~400m³/h |

| Bucket capacity | 1-20 L |

| Material temperature | ≤250 ℃ (special design) |

| Motor power | 2.2-37KW |

What is Bucket Elevator for Salt?

Bucket Elevator for Salt can transport salt vertically from a low place to a designated high place during salt production, processing, storage and transportation, with a height of up to 60 meters. It is a vertical conveying equipment for salt materials. It is widely used in the lifting of various types of granular salt, powdered salt, block salt, such as industrial salt, edible salt, sea salt, snow-melting salt, etc., with a lifting capacity of up to 400m³ per hour.

In terms of material selection, the casing of Bucket Elevator for Salt is usually made of carbon steel or stainless steel, and the hopper needs to be corrosion-resistant. Stainless steel or food-grade plastic fine materials are preferred. The hopper capacity can be adjusted according to the conveying volume. Small buckets (1~5L) are suitable for fine conveying, and large buckets (10~20L) are used for large flow operations.

What types of Bucket Elevator for Salt are there?

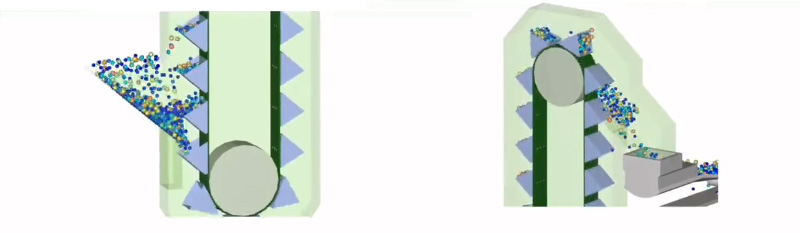

Bucket Elevator for Salt can be divided into three types: TH chain, TD belt and stainless steel Z type. The model can be selected according to the physical properties of salt (such as particle size, humidity, corrosiveness) and conveying requirements.

TH chain bucket elevator for salt: It adopts alloy steel forged chain, which is corrosion-resistant and wear-resistant. It is suitable for high temperature (≤250℃) environment, suitable for large particles or high humidity salts such as industrial salt, snow melting salt, sea salt, etc., with a lifting height of up to 60 meters and a conveying capacity of 15-365m³/h.

TD belt bucket elevator for salt: It adopts rubber belt + plastic/stainless steel hopper, which runs smoothly and reduces the flying of salt powder. It is suitable for low-abrasive salts such as edible salt and fine salt powder. The lifting height is 4-40 meters and the conveying capacity is 6-60m³/h.

Stainless steel Z-type bucket elevator for salt: 304/316L stainless steel material, rust-proof, easy to clean, in line with food hygiene standards, suitable for food-grade salt, medical salt and other scenes with high hygiene requirements, suitable for horizontal-vertical-horizontal transportation, and a lifting height of 5-30 meters.

What are the advantages of Bucket Elevator for Salt?

Salt materials are easy to absorb moisture, highly corrosive, and have different particle sizes. Ordinary conveying equipment is prone to blockage, wear, corrosion and other problems. Bucket Elevator for Salt uses corrosion-resistant stainless steel, sealed structure and wear-resistant chain to ensure that the equipment can maintain efficient and stable operation when conveying salt materials for a long time. Its core advantages include:

Strong corrosion resistance: 304/316L stainless steel is used to effectively resist salt corrosion and extend the life of the equipment.

Sealed and moisture-proof: The fully enclosed structure prevents salt from absorbing moisture and agglomerating, and the medium-deep bucket (ZH type) is used to ensure that the salt is dry and non-adhesive.

Efficient and stable: Gravity unloading or centrifugal unloading is used, with high conveying efficiency and no material return.

Strong adaptability: It can convey various forms of salt such as granular salt, powder salt, coarse salt, snow-melting salt, etc.

What is the principle of Bucket Elevator for Salt?

Bucket Elevator for Salt realizes vertical transportation of salt materials through hoppers and traction mechanisms (chains or belts). When salt materials flow into the hopper from the feed port, the motor drives the chain or belt to drive the hopper up, transports the materials to the specified height, and then discharges them from the discharge port. The empty hopper automatically returns to the bottom and continues the cycle.

Bucket Elevator for Salt Parameters

| Model | Lifting height (m) | Conveying capacity (m/h) | Applicable salts | Motor power (kW) |

| TH160 | 4.5-40 | 6-30 | Industrial salt, snow-melting salt | 2.2-7.5 |

| TH200 | 5-50 | 15-60 | Sea salt, coarse salt | 3-11 |

| TH315 | 10-50 | 35-120 | Chemical salt, high temperature salt | 5.5-18.5 |

| TD400 | 4-30 | 58-94 | Edible salt, fine salt | 11-22 |

| TH630 | 4.5-60 | 114-185 | High humidity salt, chemical salt | 18-37 |

What are the applications of Bucket Elevator for Salt?

Bucket Elevator for Salt can be used to transport various dry and fluid granular or powdered salt materials, such as industrial salt, edible salt, sea salt, mineral salt, snow-melting salt, etc. It is mainly used in salt processing, food seasoning, chemical production, water treatment and winter snow-melting agent distribution. It is used for raw material lifting and packaging in salt plants; for quantitative transportation of salt in the food industry; for salt additive feeding in chemical plants; and for the feeding of water treatment salt in the environmental protection field. Its corrosion-resistant design ensures long-term stable operation and meets the vertical transportation needs of different scenarios.

How to choose a suitable Bucket Elevator for Salt according to the characteristics of salt?

Granular salt (industrial salt, snow-melting salt): TH chain type (wear-resistant and impact-resistant)

Powdered salt (edible salt, fine salt): TD belt type (smooth operation, dust-proof)

High-humidity salt (sea salt): stainless steel Z type (corrosion-resistant and anti-caking)

High-temperature salt (chemical salt): high-temperature resistant TH type (resistant to 250°C)