Bucket Elevator for Rice

It can be used to transport rice, paddy, milled rice, etc. from one place to another, and can ensure that the rice remains intact during transportation and reduce damage.

| Price | $450.00-$9,600.00 |

| Lifting height | 10-80 meters |

| Conveying capacity | 5-800m³/h |

| Hopper type | SH deep bucket/ZH medium deep bucket/PP plastic bucket/304 stainless steel bucket |

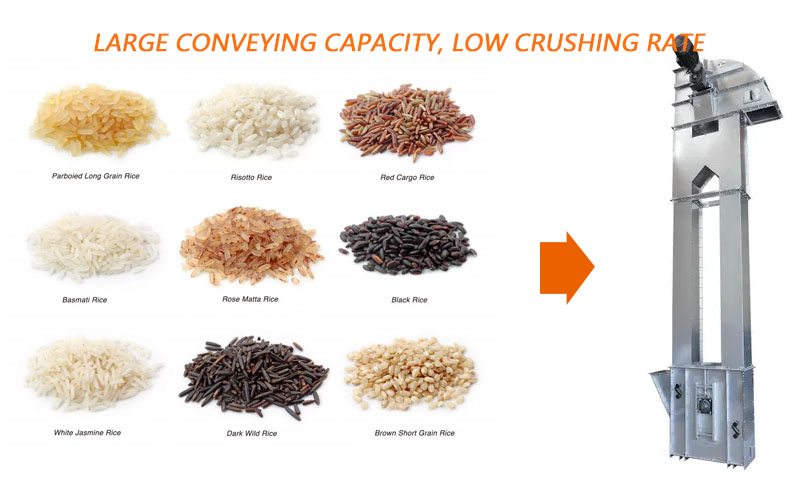

| Lifting materials | Various types of rice such as indica rice, japonica rice, glutinous rice, rice, brown rice, polished rice, etc. |

What is Bucket Elevator for Rice?

Bucket Elevator for Rice is a bucket elevator used for vertical transportation of various types of rice, such as paddy rice, brown rice, polished rice, etc. It adopts a continuous bucket conveying method, which can efficiently and stably lift rice from a low place to a high place. It can lift 800 cubic meters of rice per hour and the lifting height can reach 60 meters. It is often used in rice processing plants, grain depots, food factories and other places to ensure that the rice is not damaged or polluted during transportation, and improve production efficiency. The materials are optional, including carbon steel and stainless steel.

Bucket Elevator for Rice Video

What types of Bucket Elevator for Rice are there?

Bucket Elevator for Rice can be divided into belt type, chain type, plate chain type and Z type. The appropriate model can be selected according to the properties of the rice to be lifted and the application scenario.

| Type | Belt-type Bucket Elevator for Rice (TD type) | Ring-chain Bucket Elevator for Rice (TH type) | Plate-chain Bucket Elevator for Rice (NE type) |

| Traction component | Rubber belt/wire rope core belt | Alloy steel forged chain | High-strength wear-resistant plate chain |

| Applicable rice | Ordinary rice (indica rice, japonica rice) | High-humidity rice (such as glutinous rice) | Large-scale grain processing (such as polished rice, polished rice) |

| Features | Smooth operation, low noise, suitable for small and medium-sized rice processing plants | High temperature resistance (≤250℃), wear resistance, suitable for high-moisture rice transportation | Large conveying capacity, suitable for large grain storage |

| Lifting height | ≤40 meters | ≤60 meters | 80 meters |

| Conveying capacity | 6-60m³/h | 15-365m³/h | 15-800m³/h |

Why choose Bucket Elevator for Rice?

Bucket Elevator for Rice has a large conveying capacity and low crushing rate. It adopts inflow feeding to avoid the extrusion damage of rice caused by traditional buckets, ensure the integrity of rice grains, and fully enclosed casing design to prevent rice dust from leaking out.

Efficient conveying: adopts intensive hopper layout, large lifting capacity (15-800m³/h), to meet the needs of rice processing of different scales

Low crushing rate design: reasonable hopper design avoids extrusion and damage of rice during transportation, ensuring the integrity of rice.

Corrosion-resistant material: hoppers can be made of 304 stainless steel, nylon, polyethylene and other materials to adapt to different rice characteristics (such as high-humidity glutinous rice)

High efficiency and energy saving: intensive hopper layout, reduce return material, and drive power is 30% lower than traditional equipment.

What is the principle of Bucket Elevator for Rice?

When Bucket Elevator for Rice is in operation, the hopper is connected to a continuous belt or chain and moves in a cycle. At the bottom of the elevator, the hopper scoops rice from the hopper or storage box. As the belt or chain moves, the filled bucket is transported vertically upward. At the top of the elevator, the bucket reaches a certain position and tips over, unloading the rice into a receiving hopper or other processing unit. The empty bucket continues down and returns to the bottom, repeating the process.

Bucket Elevator for Rice Parameters

| Model | Bucket width (mm) | Lifting amount (m³/h) | Lifting height (m) | Applicable rice type |

| TD140 | 140 | 6 | ≤40 | Ordinary indica rice, japonica rice |

| TD250 | 250 | 22-26 | ≤60 | Refined rice, polished rice |

| NE100 | 100 | 15-30 | ≤50 | High humidity glutinous rice |

| NE800 | 800 | 800 | ≤80 | Large grain storage transportation |

| TH315 | 315 | 100-365 | ≤40 | High temperature drying of rice |

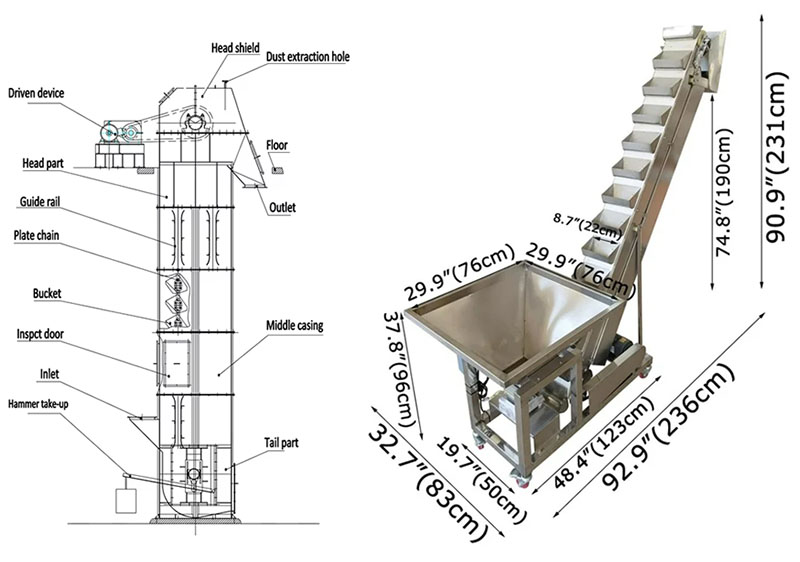

What are the components of a rice bucket elevator?

The main components of a rice bucket elevator include a drive unit (motor, reducer), a traction mechanism (belt or chain), a hopper (deep, shallow, or curved), a housing (sealed and dustproof), inlet and discharge ports, and a tensioning device (automatic or manually adjustable). The drive unit drives the traction mechanism through a head pulley, rotating the hopper in a circular motion. After loading material at the bottom, the hopper is lifted vertically to the top, where it is discharged by centrifugal force or gravity. The equipment uses wear-resistant materials (such as nylon belts and alloy chains) to reduce wear, and features anti-shatter features (such as squirrel-cage pulleys) to minimize rice breakage.

What are the uses of Bucket Elevator for Rice?

Bucket Elevator for Rice plays an indispensable role in the entire rice industry chain. In the rice mill processing link, it can realize the efficient transportation of rice from husking, polishing to packaging; in the grain storage scene, it can complete the vertical storage of rice and brown rice, greatly reducing the intensity of manual handling; in the field of food processing, whether it is glutinous rice and fragrant rice transported to the puffing and packaging production line, or as a raw material transportation for rice puffed food, rice noodles and other production lines, it is easy to handle; in export shipment, it can also be used for vertical lifting before rice container loading, significantly improving loading efficiency, with strong adaptability and efficiency, to fully meet the material transportation needs of all links.

Bucket Elevator for Rice Customer Case

| Application Scenario | Lifting Height (m) | Lifting Capacity (t/h) | Motor Power (kW) | Equipment Model/Features |

| Rice processing plant raw grain cleaning process | 3.6 - 12.0 | 5 (rice) | 1.1 | TD-5 model, automatic belt tensioning, good sealing, quiet, suitable for vertical lifting of granular materials |

| Organic rice processing color sorter secondary return grain elevator | 20 | 15 (rice) | 5.0 | Z-type elevator, using a PP plastic hopper and nylon self-lubricating chain, low-breakage conveying, suitable for multi-point unloading |

| Vertical conveying of rice in large grain processing plants | 40 | 30 (Rice) | 4.0 | TH-type chain bucket elevator, dual-channel chain structure, suitable for high-temperature (≤250°C) materials, highly wear-resistant |

How to choose a suitable Bucket Elevator for Rice?

When choosing Bucket Elevator for Rice, you can choose from rice properties (particle size, humidity, etc.), lifting amount, lifting height, and application environment.

| Selection | Specific scenario/demand | Recommended traction component type | Applicable model | Core advantages | |

| Select by rice type | Refined rice, glutinous rice (low crushing requirement) | TD belt type (tape) | TD series (such as TD140, TD200) | Smooth operation, broken rice rate <1%, protect rice integrity | |

| Paddy, brown rice (high wear resistance requirements) | TH ring chain (ring chain) | TH series (such as TH315) | Wear resistance and impact resistance, adapt to shell friction | ||

| Large grain storage (high-yield transportation) | NE plate chain (plate chain) | NE series (such as NE100-NE800) | High strength, single lifting capacity > 100 tons / day | ||

| Select according to production demand | Small rice mill (<20 tons/day) | TD belt type | TD140-TD200 | Lightweight equipment, low cost, suitable for small batch operations | |

| Medium rice mill (20-100 tons/day) | TD belt type / TH ring chain type | TD250-TH315 | Taking into account both efficiency and wear resistance, suitable for medium production | ||

| Large grain depot (>100 tons/day) | NE plate chain type | NE100-NE800 | Large load continuous operation, high lifting efficiency | ||

| Select by lifting height | ≤40 meters | TD series / TH series | All TD/TH models | Stable structure, suitable for medium and low height lifting | |

| ≤70 meters | NE series | All NE models | High-strength design, can meet the needs of large-height transportation |

bucket elevator for sugar

bucket elevator for sugar